Sound absorption and sound insulation earplug and preparing method thereof

A production method and technology of earplugs, which are applied in the direction of earplugs, single-component polystyrene artificial filaments, etc., can solve problems such as limited effects, and achieve the effects of convenient operation, short process flow, and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] S1: Prepare the spinning solution solvent in a brown grinding bottle in units of mass,

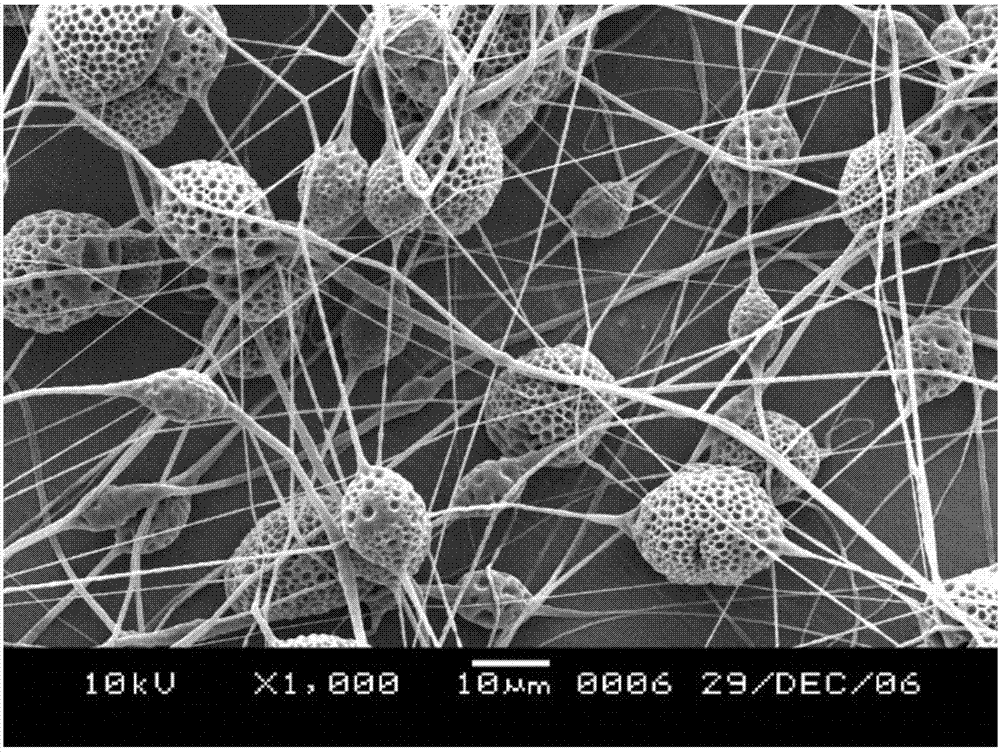

[0030] Prepare the spinning solution solvent in a brown grinding bottle in units of mass, the solvent is tetrahydrofuran and N-N dimethylformamide, the solvent mass ratio is tetrahydrofuran: N-N dimethylformamide = 3:1, weigh polystyrene As a solute, prepare a spinning solution, put the configured solution on a magnetic stirrer and stir at a constant speed for 3 hours, control the temperature and relative humidity of the experimental environment, until the solution is uniform, and prepare a solution concentration of 30wt% spinning solution;

[0031] S2: Pour the spinning solution prepared in step S1 into a syringe with an inner diameter of 0.7 mm and a capacity of 10 ml, fix the syringe on the syringe pump, and connect the injection port of the syringe and the experimental receiving plate to the positive and negative terminals of the DC high voltage power supply respectively The rec...

example 2

[0035] S1: Prepare the spinning solution solvent in the brown ground-mouth bottle by mass, and prepare the spinning solution solvent in the brown ground-mouth bottle by mass. The solvent is tetrahydrofuran and N-N dimethylformamide, and the solvent mass ratio is Tetrahydrofuran: N-N dimethylformamide = 3:1, weigh polystyrene as the solute, prepare spinning solution, put the prepared solution on a magnetic stirrer and stir at a constant speed for 3 hours, control the temperature and relative humidity of the experimental environment, until The solution is uniform, and the concentration of the prepared solution is 35wt% spinning solution;

[0036] S2: Pour the spinning solution prepared in step S1 into a syringe with an inner diameter of 0.7 mm and a capacity of 10 ml, fix the syringe on the syringe pump, and connect the injection port of the syringe and the experimental receiving plate to the positive and negative terminals of the DC high voltage power supply respectively The re...

example 3

[0040]S1: Prepare the spinning solution solvent in the brown ground-mouth bottle by mass, and prepare the spinning solution solvent in the brown ground-mouth bottle by mass. The solvent is tetrahydrofuran and N-N dimethylformamide, and the solvent mass ratio is Tetrahydrofuran: N-N dimethylformamide = 3:1, weigh polystyrene as the solute, prepare spinning solution, put the prepared solution on a magnetic stirrer and stir at a constant speed for 3 hours, control the temperature and relative humidity of the experimental environment, until The solution is uniform, and the concentration of the prepared solution is 35wt% spinning solution;

[0041] S2: Pour the spinning solution prepared in step S1 into a syringe with an inner diameter of 0.7 mm and a capacity of 10 ml, fix the syringe on the syringe pump, and connect the injection port of the syringe and the experimental receiving plate to the positive and negative terminals of the DC high voltage power supply respectively The rec...

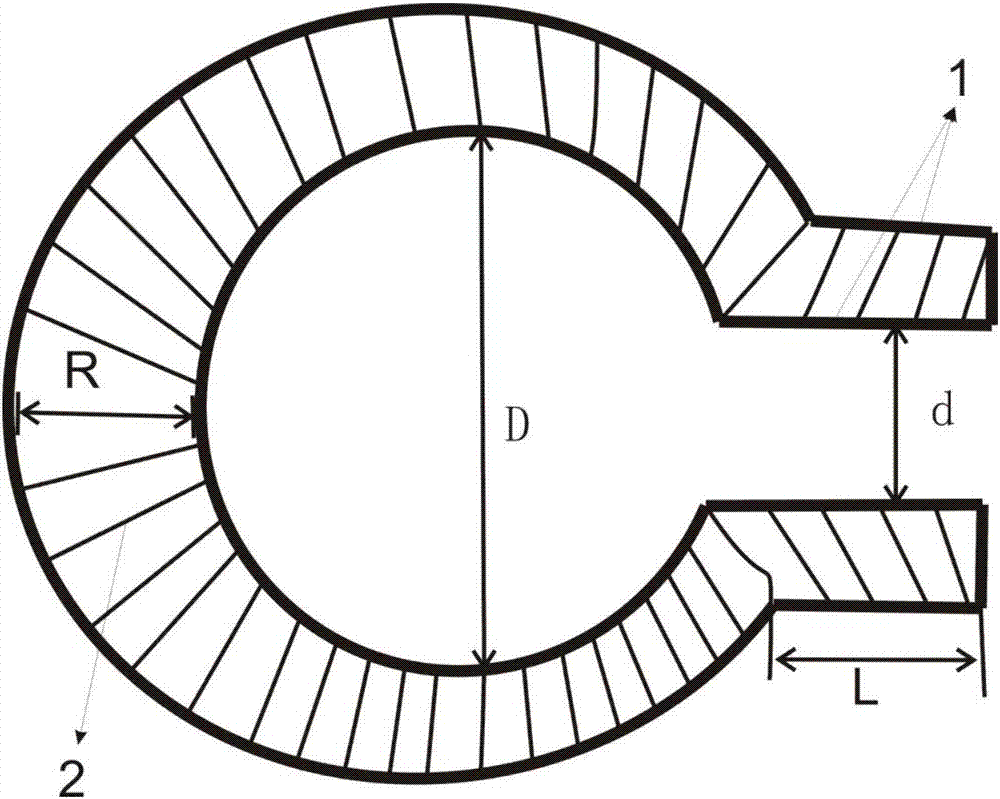

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com