Removing device for non-gum component of eucommia ulmoides bark

A technology of removing device and eucommia bark is applied in sorting, grain processing and other directions, which can solve the problems of low degree of automation, unsatisfactory extraction efficiency, large human and material resources, etc. The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

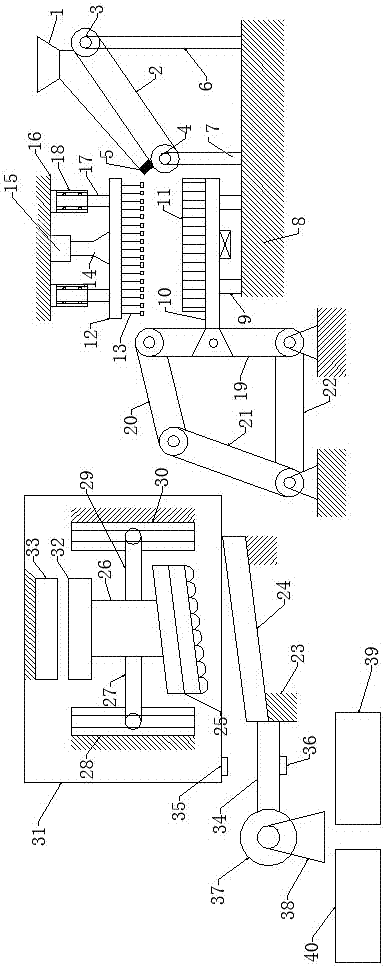

[0020] The specific implementation will be described below in conjunction with the accompanying drawings.

[0021] Such as figure 1 As shown, a device for removing non-adhesive components of Eucommia bark, including a feed hopper 1, a conveyor belt 2, a driving wheel 3, a driven wheel 4, a feeding gate 5, a first column 6, a second column 7, and a workbench 8. Fixed block 9, bottom plate 10, grid plate 11, pressure plate 12, stamping needle 13, push rod 14, hydraulic cylinder 15, first mounting seat 16, guide rod 17, guide column 18, rocker 19, connecting rod 20 , crank 21, connecting rod 22, block 23, inclined plate 24, boss 25, vertical bar 26, left cross bar 27, left guide rail 28, right cross bar 29, right guide rail 30, second mount 31, permanent magnet 32. Electromagnet 33, rotating plate 34, infrared emitter 35, receiver 36, rotating disc 37, fixed table 38, first material storage box 39, second material storage box 40.

[0022] A conveyor belt 2 is arranged below the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com