Manufacturing method for metal shell body, metal shell body and electronic equipment using metal shell body

A technology of metal shell and manufacturing method, which is applied in the direction of metal shell, etc., can solve the problems of sundries, easy to break knives, long processing time, etc., to prevent water, sundries or sharp objects from piercing, beautiful and unique Effects of improved appearance and design freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

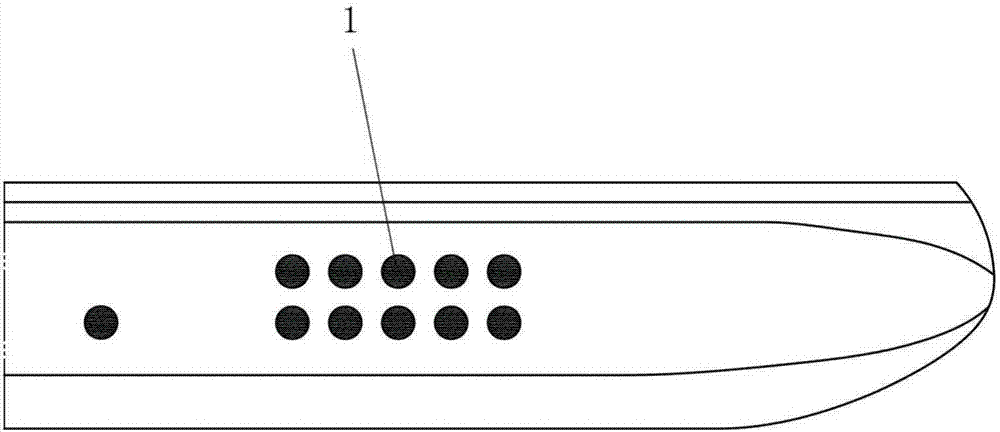

[0023] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. The metal casing referred to in the present invention can be the metal casing of various electronic devices such as mobile phone, tablet computer, laptop computer, etc., for the convenience of description, in the following description, the metal casing of mobile phone is used as an example to illustrate, and for The same symbols are used for the same components.

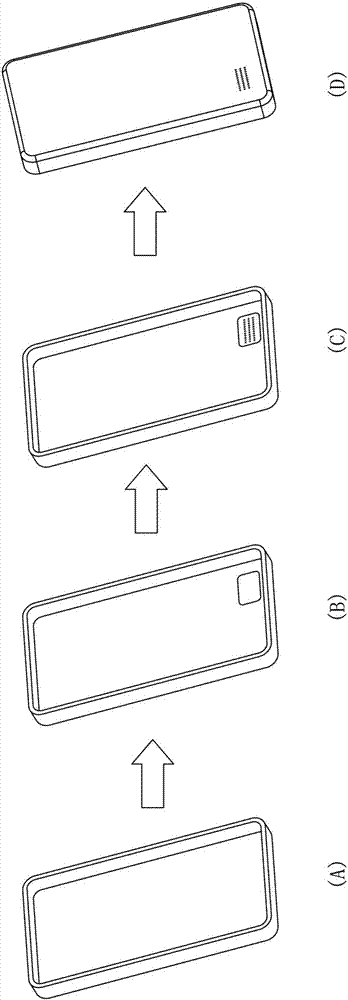

[0024] figure 2 It is a schematic diagram showing a part of the flow of the metal casing manufacturing method of the present invention.

[0025] When making a metal case for a mobile phone, it is first necessary to prepare a metal plate of a predetermined size.

[0026] Then, the sheet metal is processed into a metal shell having a predetermined shape by stamping and forging and CNC processing or only by CNC processing, such as figure 2 Step (A).

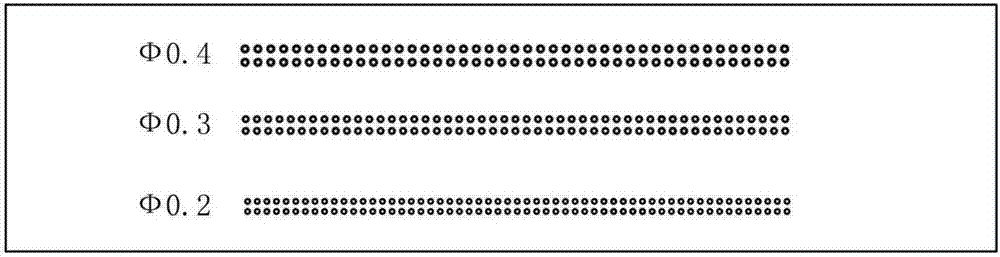

[0027] Then, in the predetermined area of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com