Manual composite blanking die

A punching die and concave die technology, which is applied in the field of manual compound punching dies and punching dies, can solve the problems of increasing production costs, manual processing, and low work efficiency, and achieve the goals of improving work efficiency, reducing procedures, and saving costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

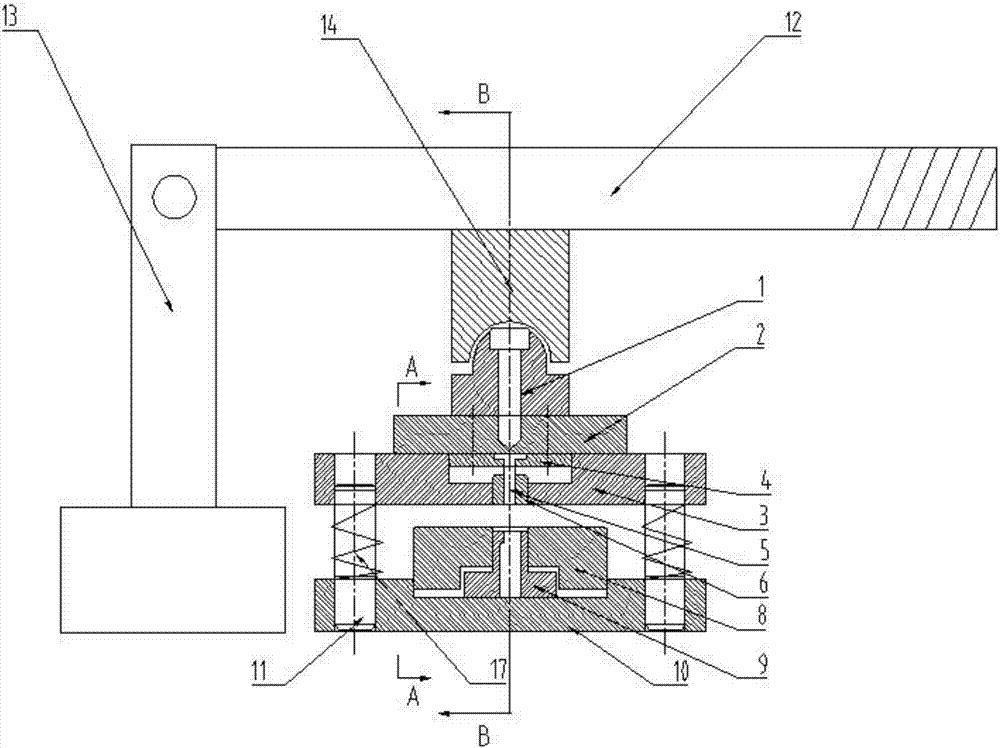

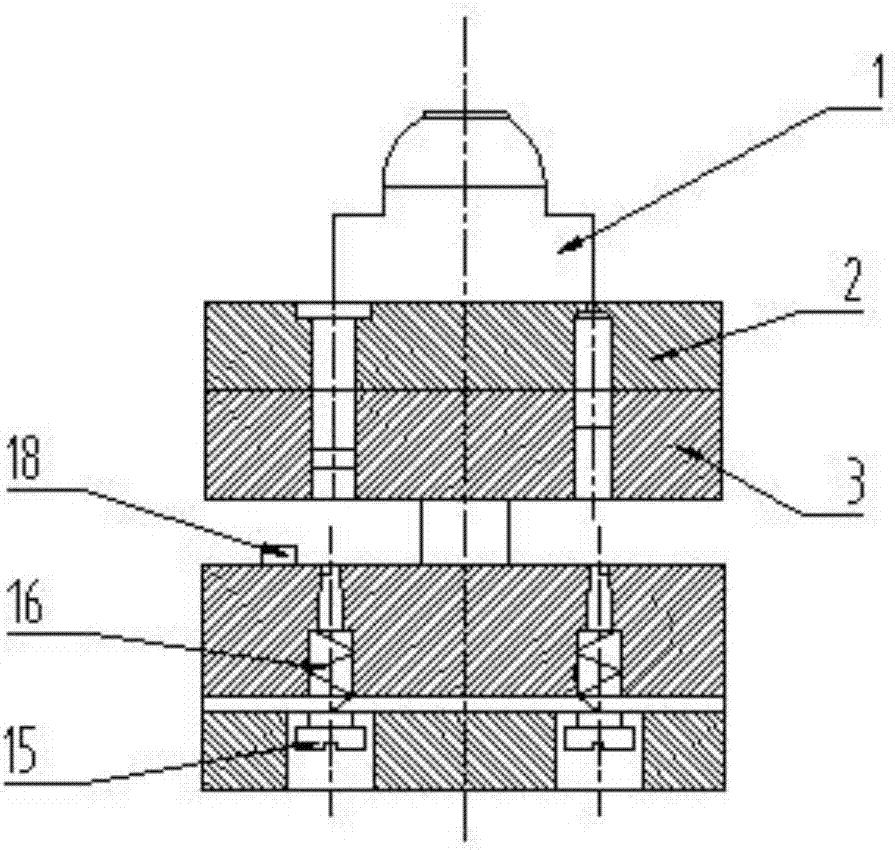

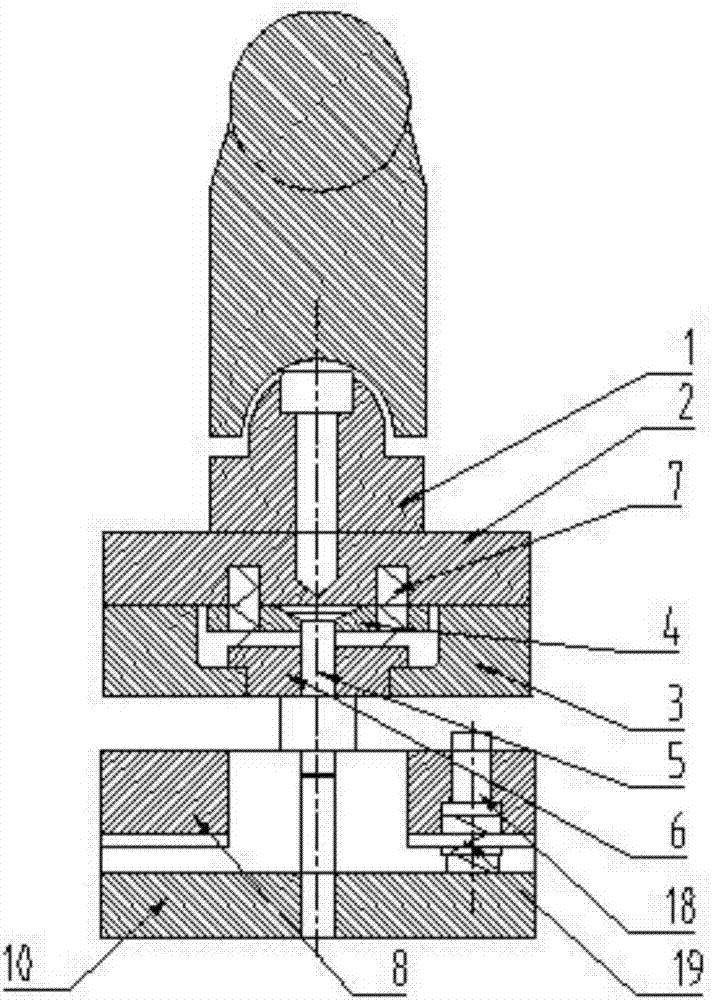

[0013] The present invention will be further described below in conjunction with accompanying drawing.

[0014] Such as Figure 1 to Figure 3 Shown, a kind of manual composite blanking die, comprises upper mold and lower mold, also comprises manual pressure bar, and described upper mold comprises handle mold 1, top plate 2, die 3, punch fixing plate 4, and described top plate 2 It is connected with the punch fixing plate 4 by screws, the top plate 2 and the die 3 are connected by cylindrical pins, the punch 5 is embedded on the punch fixing plate 4, the ejector 6 is in clearance fit with the die 3, the ejector 6, the die A compression spring 7 is arranged between the mold 3 and the punch fixing plate 4; the lower mold includes a stripping plate 8, a convex and concave die 9 and a bottom plate 10, and the convex and concave mold 9 is fixed on the bottom plate 10 by screws, and the stripping plate 8 passes through The screw 15 and the compression spring 2 16 are connected on th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap