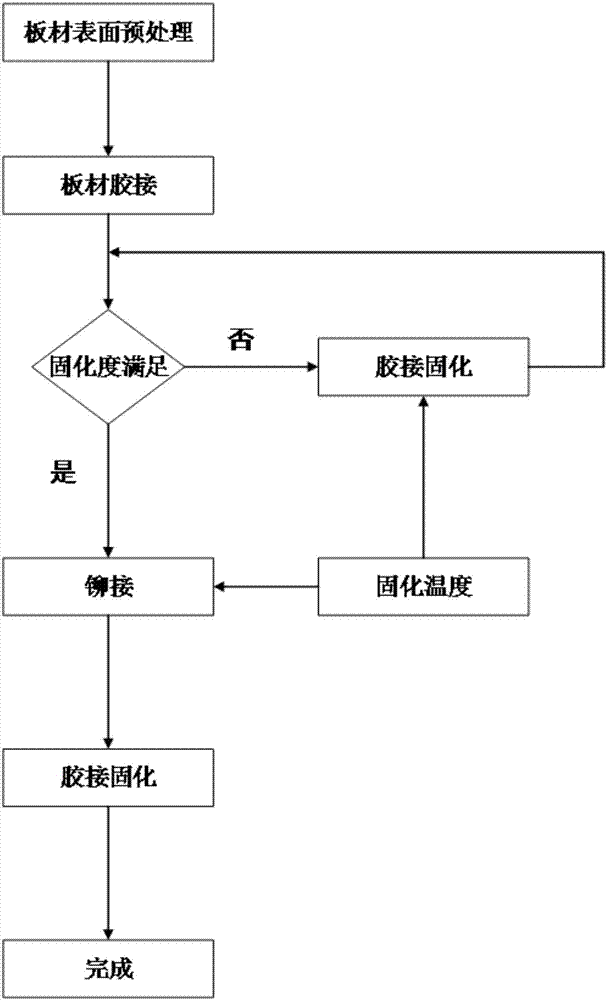

Pre-bonding curing sticking riveting process

A technology of adhesive bonding and process, applied in the field of adhesive riveting composite connection process, can solve problems such as separation, achieve the effect of reducing process, reducing deformation resistance and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

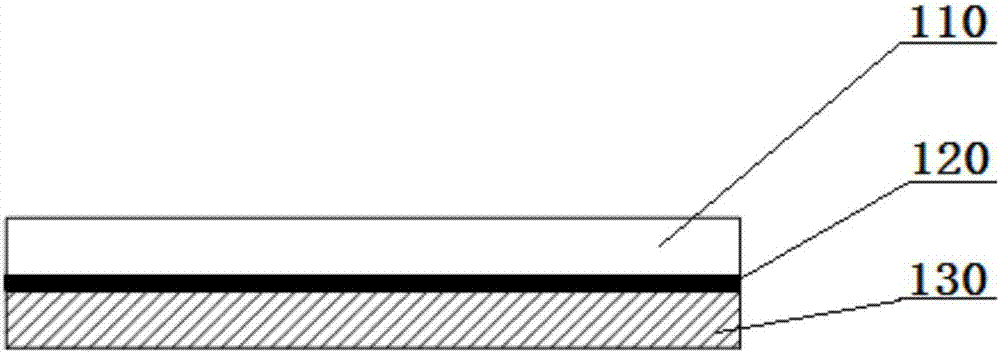

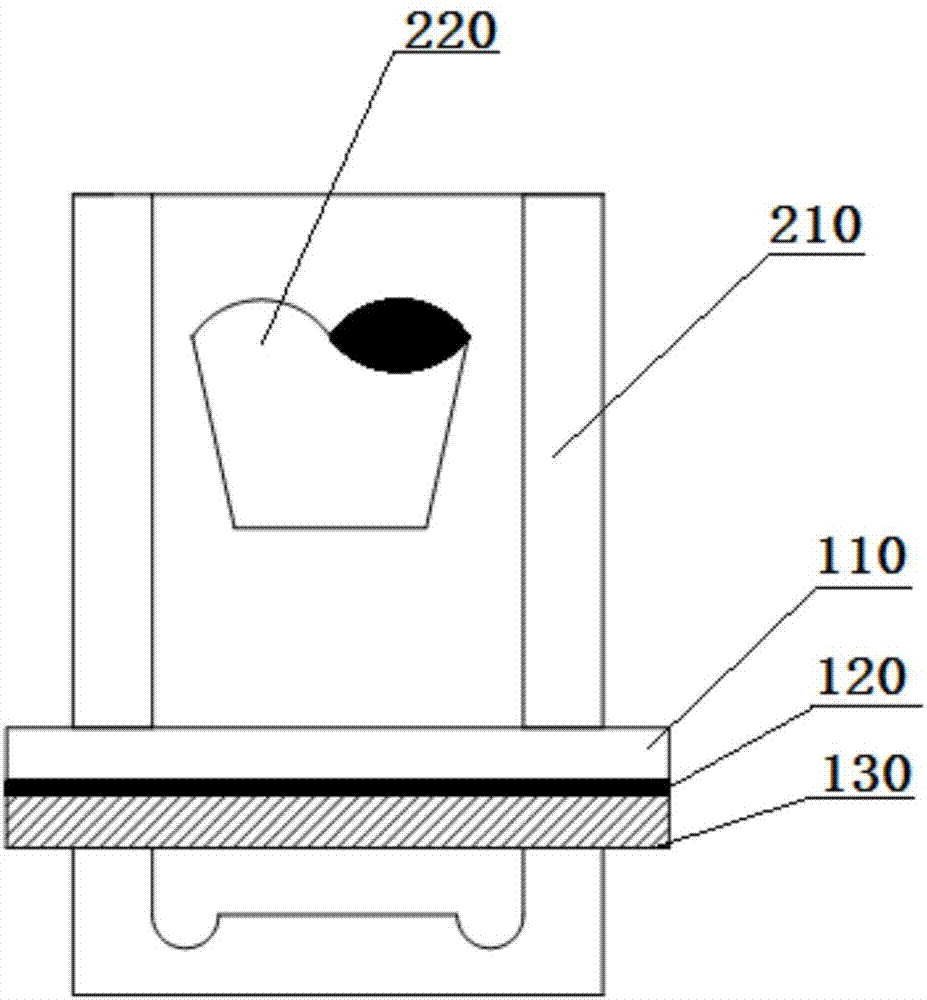

[0035] Step 1. At room temperature, pre-treat the upper and lower sheets to remove impurities, apply the polymer adhesive evenly on one side of the sheet for bonding, the thickness of the adhesive layer is 0.1-0.3mm, remove the excess around the sheet Adhesive, start curing; control the curing temperature at 80-200°C, stop curing when the curing degree is 0.18, and obtain the glued board;

[0036] In this step, the material of the upper and lower floor panels can be selected from metal and metal panels, metal and non-metal panels, non-metal and non-metal panels, as a preference, in the present invention, the upper and lower panels The materials are low carbon steel plate and copper plate respectively.

[0037] As a preference, the thickness of the adhesive layer in the present invention is 0.1mm, and the mechanical properties of the adhesive layer with this thickness are the best, because as the thickness of the adhesive layer increases, the mechanical properties gradually dec...

Embodiment 2

[0046] Step 1. At room temperature, pre-treat the upper and lower sheets to remove impurities, apply the polymer adhesive evenly on one side of the sheet for bonding, the thickness of the adhesive layer is 0.1-0.3mm, remove the excess around the sheet Adhesive, start curing; control the curing temperature at 80-200°C, stop curing when the curing degree is 0.37, and obtain the glued board;

[0047] In this step, the material of the upper and lower floor panels can be selected from metal and metal panels, metal and non-metal panels, non-metal and non-metal panels, as a preference, in the present invention, the upper and lower panels The materials are low carbon steel plate and copper plate respectively.

[0048] As a preference, the thickness of the adhesive layer in the present invention is 0.1mm, and the mechanical properties of the adhesive layer with this thickness are the best, because as the thickness of the adhesive layer increases, the mechanical properties gradually dec...

Embodiment 3

[0057] Step 1. At room temperature, pre-treat the upper and lower sheets to remove impurities, apply the polymer adhesive evenly on one side of the sheet for bonding, the thickness of the adhesive layer is 0.1-0.3mm, remove the excess around the sheet The adhesive starts to cure; the curing temperature is controlled at 80-200°C, and when the curing degree is 0.45, the curing is stopped to obtain a glued board;

[0058] In this step, the material of the upper and lower floor panels can be selected from metal and metal panels, metal and non-metal panels, non-metal and non-metal panels, as a preference, in the present invention, the upper and lower panels The materials are low carbon steel plate and copper plate respectively.

[0059] As a preference, the thickness of the adhesive layer in the present invention is 0.1mm, and the mechanical properties of the adhesive layer with this thickness are the best, because as the thickness of the adhesive layer increases, the mechanical pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com