Coating embossing process

A technique of painting and embossing, applied in the painting and embossing process. It can solve the problems of slow volatilization of taste, difficult curing, and long decoration cycle, and achieve the effects of simple equipment requirements, guaranteed life, and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

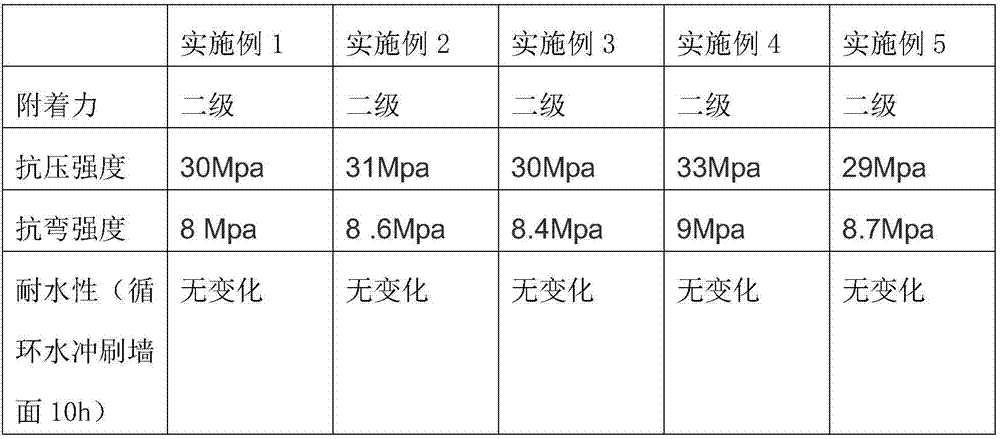

Examples

Embodiment 1

[0025] A coating relief process, comprising the following steps,

[0026] Step 1, use a spatula to remove the wall skin on the wall to be painted to ensure that the wall is smooth and clean; in order to ensure the adhesion of the primer, it also includes using a brush to clean up the larger particles floating on the wall. Large particles mainly refer to the size greater than 2mm;

[0027] Step 2, roll-coat the anti-alkali sealing primer to the wall surface of the belt to ensure the smoothness of the anti-alkali sealing primer, and control the paint film thickness of the primer to be 0.1mm; in the present embodiment, the anti-alkali sealing primer comes from Zhengzhou Senta Chemical Co., Ltd., the model is ST‐H06‐102;

[0028] Step 3: Decorate the plaster on the wall with a spatula, spray water mist on the paint film of the primer, control the coverage of the water mist on the wall to 50%, and level the plaster with a spatula. The plaster includes the following weights Parts ...

Embodiment 2

[0034] A painting relief process, comprising the following steps, step 1, using a spatula to remove the wall skin of the wall surface to be painted, so as to ensure that the wall surface is smooth and clean;

[0035] Step 2, roll-coat the penetrating primer to the painted wall surface to ensure the smoothness of the penetrating primer, and control the paint film thickness of the primer to 1.3mm; the penetrating primer comes from Jiamei Latex Paint Co., Ltd.;

[0036] Step 3, use a spatula to decorate the plaster on the wall, spray water mist on the paint film of the primer, control the coverage of the water mist on the wall to 65%, and level the plaster with a trowel, wherein the plaster includes the following weights Parts of each material: 2 parts of water, 1.5 parts of gypsum powder, 1 part of stone powder, 0.5 parts of polyester fiber;

[0037] Step 4. When the gypsum is 60% to 80% dry, place a model board with a hollowed-out pattern on the area where relief is required on...

Embodiment 3

[0043] A painting relief process, comprising the following steps, step 1, using a spatula to remove the wall skin of the wall surface to be painted, so as to ensure that the wall surface is smooth and clean;

[0044] Step 2, roll the primer to the painted wall to ensure the smoothness of the primer, and control the film thickness of the primer to 0.3mm; the primer is a compound alkali-resistant primer of acrylic emulsion and silica sol, and the acrylic emulsion and The silica sol composite alkali-resistant primer includes the following materials in parts by weight, 1 part of silica sol, 30 parts of acrylic acid emulsion, 10 parts of diatomaceous earth, and 10 parts of pebble powder; the particle size of the pebble powder is 0.1mm.

[0045] Step 3, use a spatula to embellish the plaster on the wall, spray water mist on the paint film of the primer, control the coverage of the water mist on the wall to 60%, and level the plaster with a trowel, wherein the plaster includes the fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com