Active and passive energy storage combined driver

A driver and combined technology, applied in the field of robotics, can solve problems such as low energy conversion efficiency, and achieve the effects of improving practicability, energy conversion rate, and energy optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in more detail below in conjunction with accompanying drawing

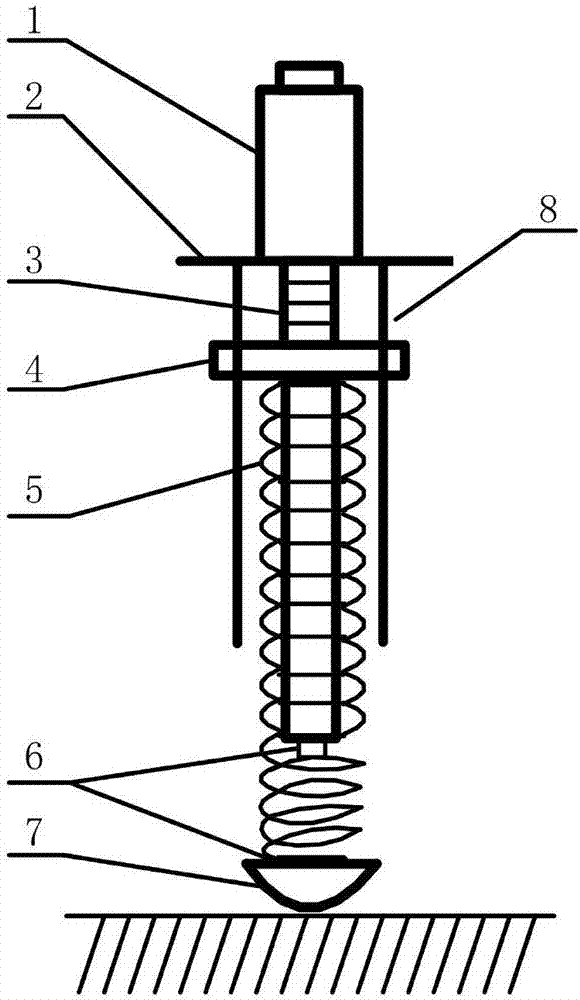

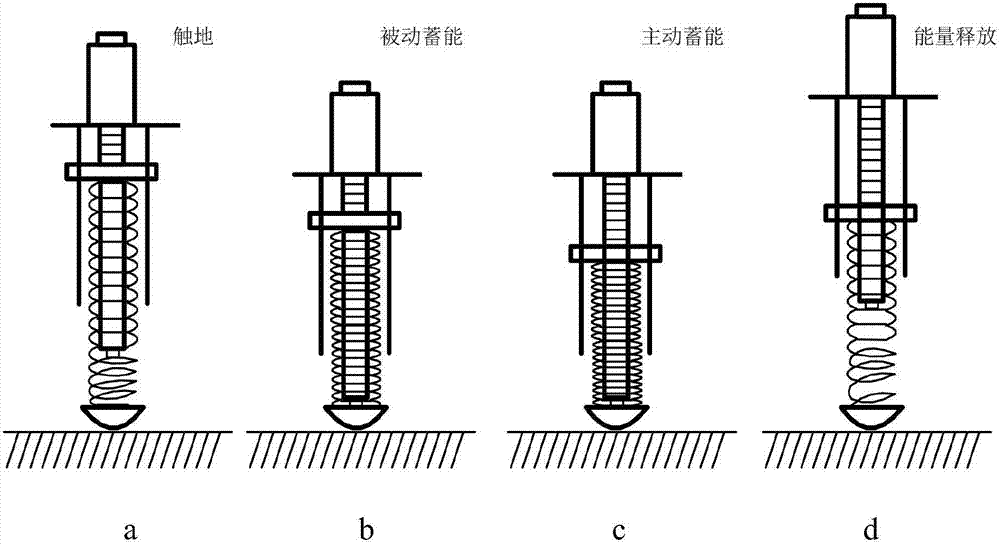

[0014] to combine Figure 1-2 , the present invention is a combination of active and passive energy storage driver, which is applied to a single-foot jumping robot, including a motor mounting frame 2, a servo motor 1 is fixedly installed above the motor mounting frame, and the output shaft of the servo motor 1 is directly It is connected with the ball screw 3, and the flange guide device 8 is fixed under the motor mounting frame 2, and the ball nut 4 matched with the ball screw is slidably set on the linear fixed guide rail, so as to ensure that the ball nut will not move during the movement. When the rotation occurs, an energy storage spring 5 is fixed below the ball nut 4, the energy storage spring is set on the ball screw, and the lower end of the energy storage spring is fixed with an elastic sole 7, the lower end of the ball screw screw 3 and the upper end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com