Stack-up type feeding device and operating method thereof

A feeder and stacking technology, which is applied in the direction of unstacking, transportation and packaging of objects, can solve the problems of high manufacturing cost and complicated mechanical structure, and achieve the effect of low production cost, simple working method and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

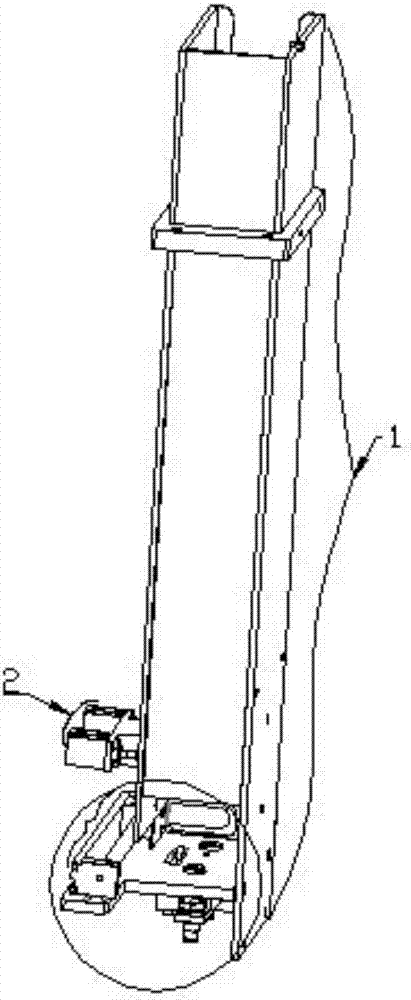

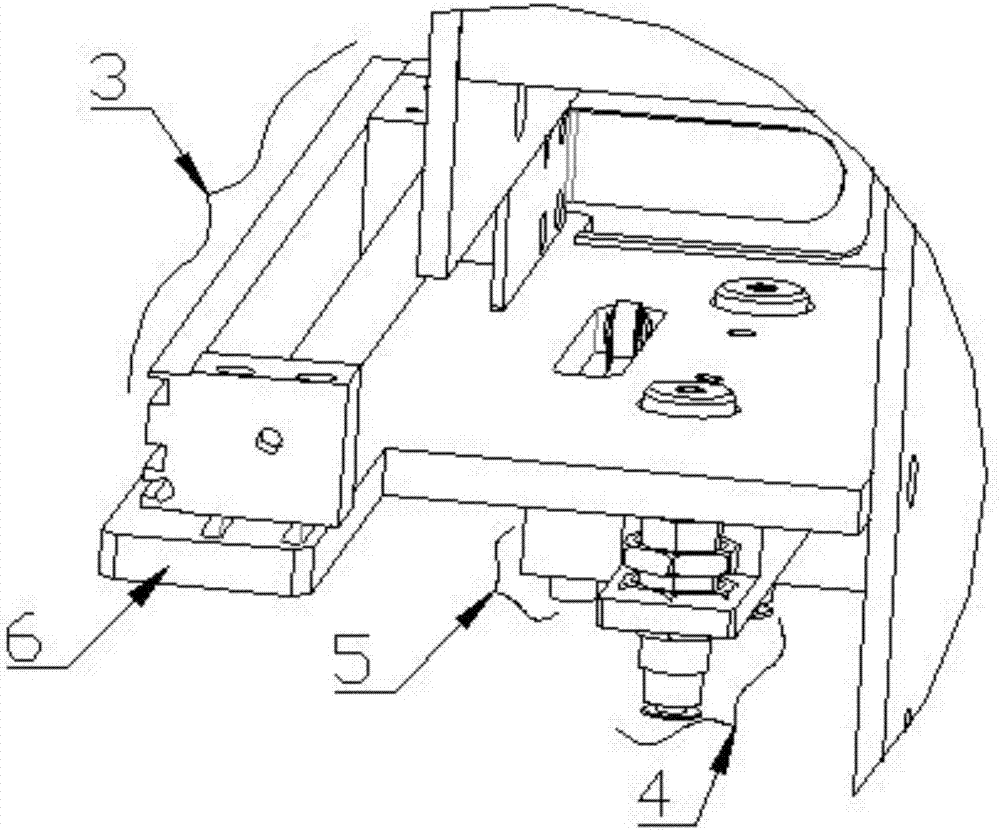

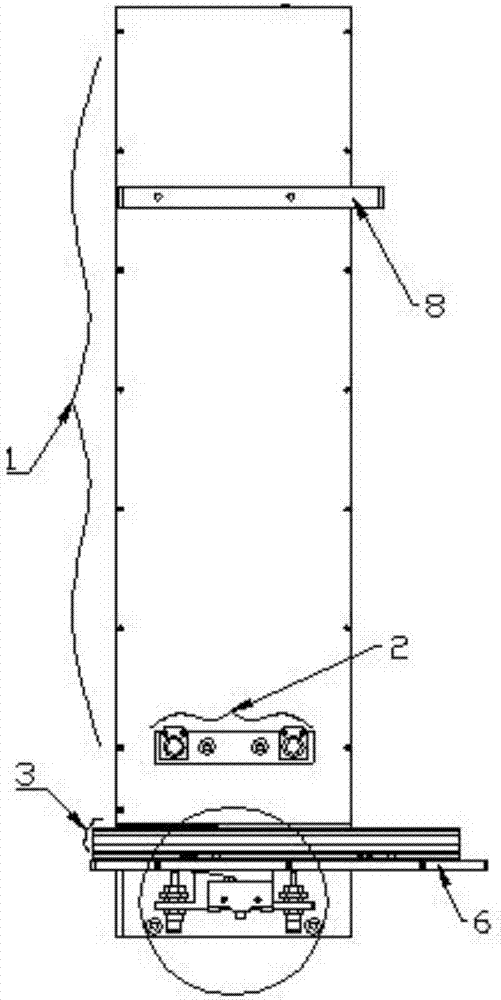

[0070] Embodiment one, such as Figure 1-13 , a stacked feeding machine, including the lower bin 1, and also includes a U-shaped frame 8, the U-shaped frame 8 is stuck above the lower bin 1 and fixed with bolts, and the inside of the lower bin 1 is placed Box-shaped material 7, the front of the lower material bin 1 is provided with a side clamping mechanism 2 close to the bottom, and the bottom of the lower material bin 1 is provided with a feeding device, and the feeding device includes a feeding device connected to the lower end of the lower material bin 1. plate 6, the feeding plate 6 protrudes from the conveying plate directly in front of the downward hopper 1, the conveying mechanism 3 is fixed above the conveying plate, and the ejecting mechanism 4 and the sensor 5 are fixed below the feeding plate 6 The lower silo 1 includes a front panel 101, a back panel 102, a left side panel 103 and a right side panel 104 connected together by screws and the upper ends are flush. S...

Embodiment 2

[0071] Embodiment two, such as Figure 1-13 , is basically the same as the first embodiment. Preferably, the sensor 5 includes a main body 501, a spring 502 and a contact 503 located below the spring 502 are arranged above the main body 501, and a roller 504 is provided at the end of the spring 502. , the feeding plate 6 is provided with a rectangular notch above the shrapnel 502, the roller 504 passes through the rectangular notch, the main body 501 includes a pressure sensor connected to the contact 503 and a contact rotary speed sensor connected to the roller 504 ; Main body 501, shrapnel 502, contact 503, roller 504 these 4 parts together form a limit switch with roller, namely inductor 5; The friction force by which the small material box is pushed out from the silo.

Embodiment 3

[0072] Embodiment three, such as Figure 1-13 , basically the same as the second embodiment, preferably, the side clamp drive 202 and the ejector drive 402 are both telescopic cylinders with electromagnetic reversing valves, and both the clamping rod and the ejector rod are the piston rods of the telescopic cylinder , the conveying drive 301 is a magnetically coupled cylinder with an electromagnetic reversing valve, the inside of the guide rod 303 is a piston rod with a magnetic ring armor, and the slider 304 is provided with a sleeve hole, and the inside of the sleeve hole A magnetic ring B that is magnetically opposite to the magnetic ring A is fixed, and the slider 304 is sleeved on the guide rod 303 through the magnetic ring B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com