Making method and application of Hanxiangmi dry white wine

A dry white wine and Hanxiangmi dry white technology is applied in the brewing field of Hanxiangmi dry white wine, which can solve the problems of poor aroma, low content of dry extracts, weak wine and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

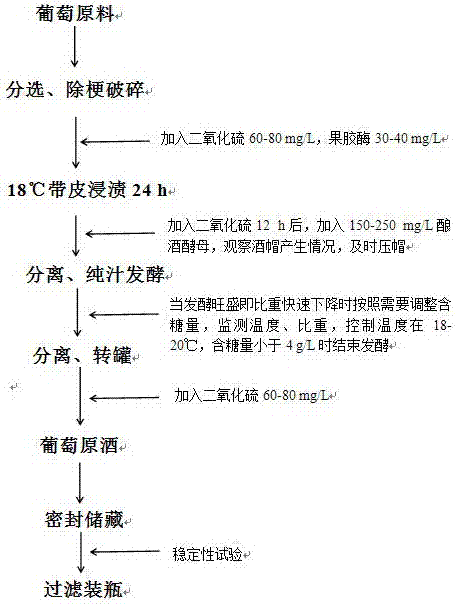

Method used

Image

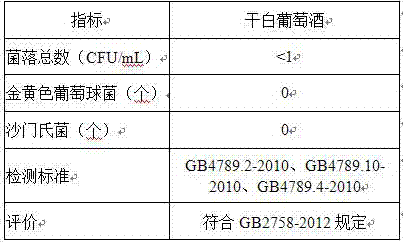

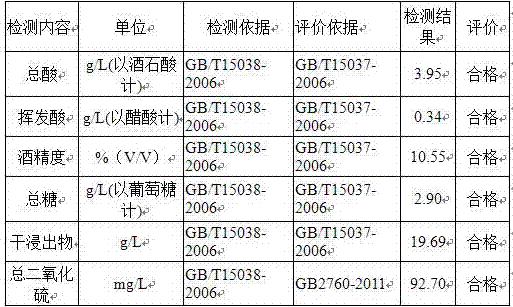

Examples

Embodiment 1

[0036] (1) Grape sorting: remove moldy and damaged grape berries, rotten leaves, sundries, etc.;

[0037] (2) De-stemming and crushing: The grape raw materials are 100% de-stemmed and crushed and put into the tank. Sulfur dioxide is added while feeding, and 60 mg of sulfur dioxide and 40 mg of pectinase are added to each kilogram of grape raw materials, and the closed cycle is performed once;

[0038] (3) Short-term immersion: add 200 mg / L of Saccharomyces cerevisiae after adding sulfur dioxide for 12 hours, control the temperature to 18°C, soak for 24 hours, observe the production of wine caps, and press the caps in time;

[0039] (4) Pure juice fermentation: separate the macerated grape mash residue, and ferment the pure juice. When the fermentation is vigorous, that is, the specific gravity drops rapidly, the sugar content is adjusted as needed. According to the potential alcohol content and the target alcohol content 12% (V / V ), 17g / L is converted into 1% (V / V) alcohol con...

Embodiment 2

[0060] comparative test

[0061]

[0062] Conclusion: The sensory evaluation score, dry extract content, aroma component content, total phenol content, total anthocyanin content and chromaticity value of the Hanxiangmi dry white wine brewed by the method of the present invention are higher than those of the traditional method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com