Method for increasing yield of oligopeptide prepared by liquid state fermentation

A technology of liquid fermentation and oligopeptide, applied in the field of fermentation engineering, can solve problems such as oligopeptide, and achieve the effect of strong absorption, vigorous growth and metabolism, and promoting the growth of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] (1) Preparation of fermented seed liquid

[0066] Same as Step 1 of Comparative Example 1.

[0067] (2) Liquid fermentation of Bacillus subtilis

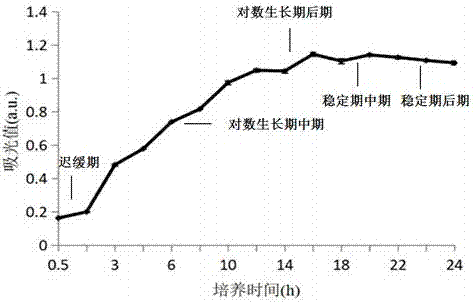

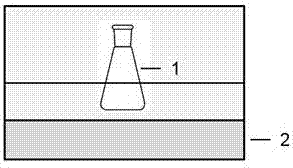

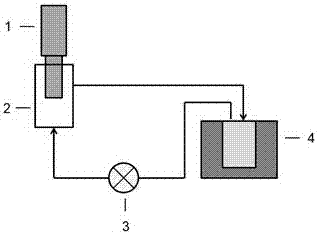

[0068] Inoculate 10% Bacillus subtilis seed solution into a triangular flask containing soybean meal medium, place it at 200 r / min, and culture it on a shaker at 36°C for 9 hours. , and the water in the ultrasonic water tank is flush with the liquid level of the bacterial solution in the triangular flask ( figure 2 ). After frequency-sweeping ultrasonic treatment for 1.5 h, they were cultured on a shaker for 14 h to enter the late stage of stable growth, and then subjected to countercurrent energy-concentrating ultrasonic treatment for 0.5 h ( image 3 ), and the medium was kept at 45°C for 4 h.

[0069] Frequency-sweeping divergent ultrasound parameters: power density 60 W / L, frequency 24±2 kHz, intermittent ratio 5 s:5 s.

[0070] Countercurrent focused ultrasonic parameters: power 500 W, frequency 40 kHz, intermitten...

Embodiment 2

[0075] (1) Preparation of fermented seed liquid

[0076] Same as Step 1 of Comparative Example 1.

[0077] (2) Liquid fermentation of Bacillus subtilis

[0078] Inoculate 10% Bacillus subtilis seed solution into a triangular flask containing soybean meal medium, place it at 200 r / min, and culture it on a shaker at 36°C for 9 hours. , and the water in the ultrasonic water tank is flush with the liquid level of the bacterial solution in the triangular flask ( figure 2 ). After frequency-sweeping ultrasonic treatment for 0.75 h, they were cultured on a shaker for 14 h to enter the late stage of stable growth, and then subjected to countercurrent energy-concentrating ultrasonic treatment for 0.75 h ( image 3 ), and the medium was kept at 50°C for 4 h.

[0079] Frequency-sweeping divergent ultrasound parameters: power density 60 W / L, frequency 24±2 kHz, intermittent ratio 5 s:5 s.

[0080] Countercurrent focused ultrasonic parameters: power 500 W, frequency 40 kHz, intermitt...

Embodiment 3

[0085] (1) Preparation of fermented seed liquid

[0086] Same as Step 1 of Comparative Example 1.

[0087] (2) Liquid fermentation of Bacillus subtilis

[0088] Inoculate 10% Bacillus subtilis seed solution into a triangular flask containing soybean meal medium, place it at 200 r / min, and culture it on a shaker at 36°C for 9 hours. , and the water in the ultrasonic water tank is flush with the liquid level of the bacterial solution in the triangular flask ( figure 2 ). After frequency-sweeping ultrasonic treatment for 1 h, they were cultured on a shaker for 14 h to enter the late stage of stable growth, and then subjected to countercurrent energy-concentrating ultrasonic treatment for 1 h ( image 3 ), and the medium was kept at 55°C for 4 h.

[0089] Frequency-sweeping divergent ultrasound parameters: power density 60 W / L, frequency 24±2 kHz, intermittent ratio 5 s:5 s.

[0090] Countercurrent focused ultrasonic parameters: power 500 W, frequency 40 kHz, intermittent ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com