Method for producing clavulanic acid kalium with inert carrier adsorption of solid state continuous fermentation

A technology of potassium clavulanate and inert carrier, which is applied in the field of continuous fermentation of potassium clavulanate by adsorption of inert carrier in solid state, and can solve the problems of high energy consumption and low output of potassium clavulanate, achieve low energy consumption and improve production efficiency , to achieve a continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Prepare potassium clavulanate with the method of the present invention, its step is as follows:

[0058] 1) Preparation of Streptomyces clavulicularis seed solution

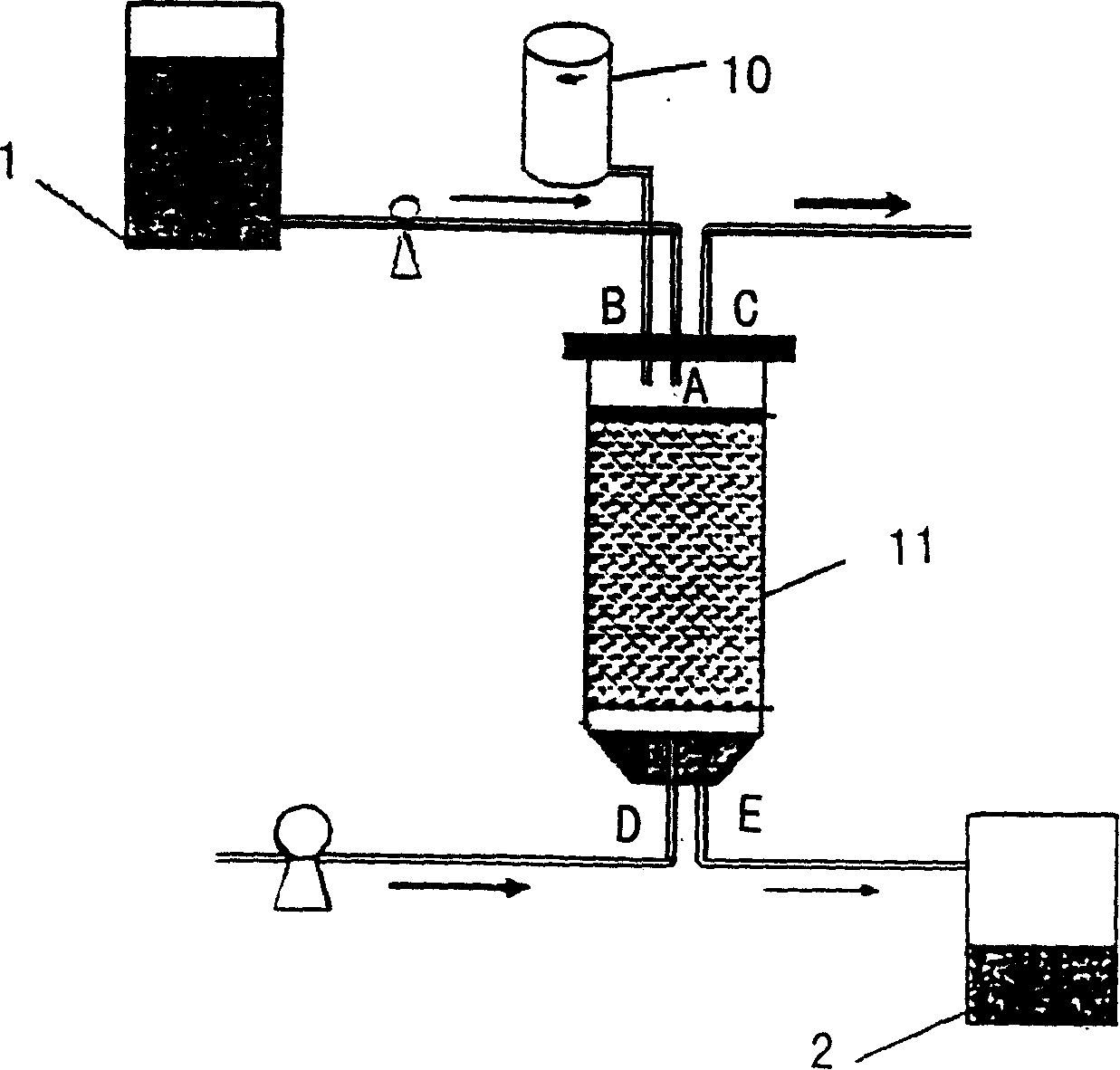

[0059] Streptomyces clavuligerus (Streptomyces, Clavuligerus, CCRC11518=ATCC27064, whose preservation number is CCMCC 4.3) purchased from the General Microorganism Collection Center of China Microorganism Collection Management Committee was inoculated on the slant medium of Streptomyces clavuligerus, and inoculated and cultivated at 29°C; Cultivate in the Streptomyces clavulicularis seed culture medium to produce mycelium, obtain the Streptomyces clavulinformis seed liquid and dress in figure 1 Streptomyces clavulicularis fermentation seed liquid storage tank 10 in;

[0060] The Streptomyces clavulis slant culture medium is Gao's No. 1 medium, and its contained components and proportions are: soluble starch 20g, KNO 3 1g, MgSO 4 0.5g, K 2 HPO 4 0.5g, NaCl 0.5g, FeSO 4 0.01g, 15-20g agar, 1000ml w...

Embodiment 2

[0076] Prepare potassium clavulanate with the method of the present invention, its step is with embodiment 1, and embodiment 1 difference is:

[0077] The inert carrier used in this embodiment is a polyvinyl chloride foam carrier;

[0078] In step 3) of this embodiment, the Streptomyces clavuliformis fermentation medium storage tank was pumped from the top of the Streptomyces clavuliformis fermentation medium into the fermenter at a flow rate of 0.04 ml / min through a peristaltic pump.

[0079] The flow rate at which the Streptomyces clavulosa seed liquid in the seed liquid storage tank in step 3) of this embodiment is pumped into the fermenter from its top is 0.04 ml / min.

[0080] In step 3) of this embodiment, while the Streptomyces clavulosa culture medium flows from top to bottom and ferments to produce fermentation metabolites, the flow rate of sterile air entering the fermenter from the air inlet at the bottom of the fermenter is 13ml / min.

Embodiment 3

[0082] Prepare potassium clavulanate with the method of the present invention, its step is with embodiment 1, and embodiment 1 difference is:

[0083] The inert carrier used in this embodiment is a polyvinyl chloride foam carrier;

[0084] In step 3) of this embodiment, the Streptomyces clavulicularis fermentation medium storage tank was pumped from the top of the Streptomyces clavuliformis fermentation medium into the fermenter at a flow rate of 0.05 ml / min through a peristaltic pump.

[0085] The Streptomyces clavulosa seed liquid in the seed liquid storage tank in step 3) of this embodiment is pumped into the fermenter at a flow rate of 0.05 ml / min from its top.

[0086] In step 3) of this embodiment, while the Streptomyces clavulosa culture medium flows from top to bottom and ferments to produce fermentation metabolites, the flow rate of sterile air entering the fermenter from the air inlet at the bottom of the fermenter is 15ml / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com