Vacuum furnace quenching oil cooling system used for thermal treatment

A technology of cooling system and quenching oil, which is applied in heat treatment equipment, heat treatment process control, quenching device, etc., can solve the problems that it is difficult to meet the requirements of rapid cooling of quenching oil and the uniformity of quenching oil cooling, and achieve flexible cooling speed, The effect of adjusting the cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

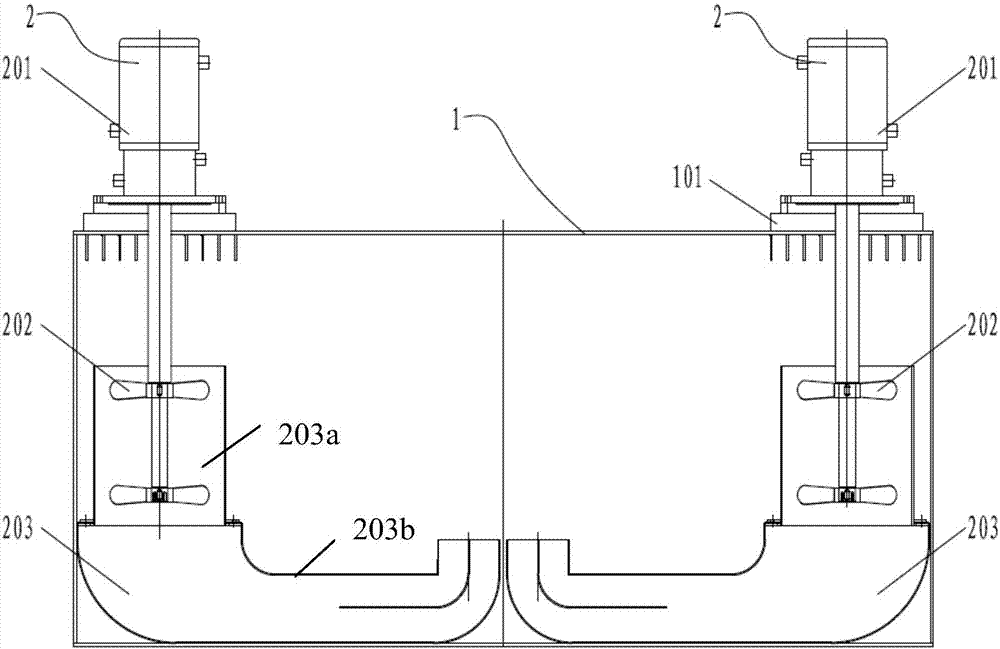

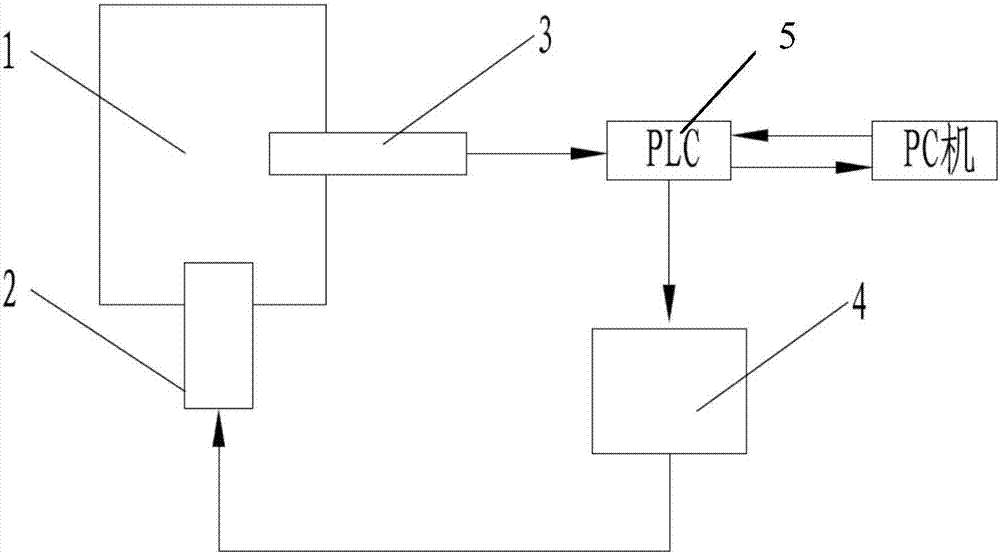

[0015] like figure 1 and figure 2 As shown, in a specific embodiment, the vacuum furnace quenching oil cooling system for heat treatment provided by the present invention includes a quenching oil tank 1, a quenching oil stirring and lifting device 2 and other components.

[0016] Water-cooled walls 101 are laid on the left and right ends of the top wall of the quenching oil tank 1 , and water circulation pipes are installed in the water-cooled walls 101 , and the water-cooled walls 101 can exchange heat with the external environment.

[0017] In this embodiment, two sets of quenching oil stirring and lifting devices 2 are provided, which are respectively arranged at the positions of two water-cooled walls 101. Each group of quen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com