Construction method for large steel plate embedded part of wall

A technology of embedded parts and construction technology, applied in the direction of construction, building structure, etc., can solve the problems of difficult adjustment, time-consuming and laborious, misalignment of steel plate embedded parts, etc., achieving obvious technical and economic effects, simple and convenient process, and speeding up The effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

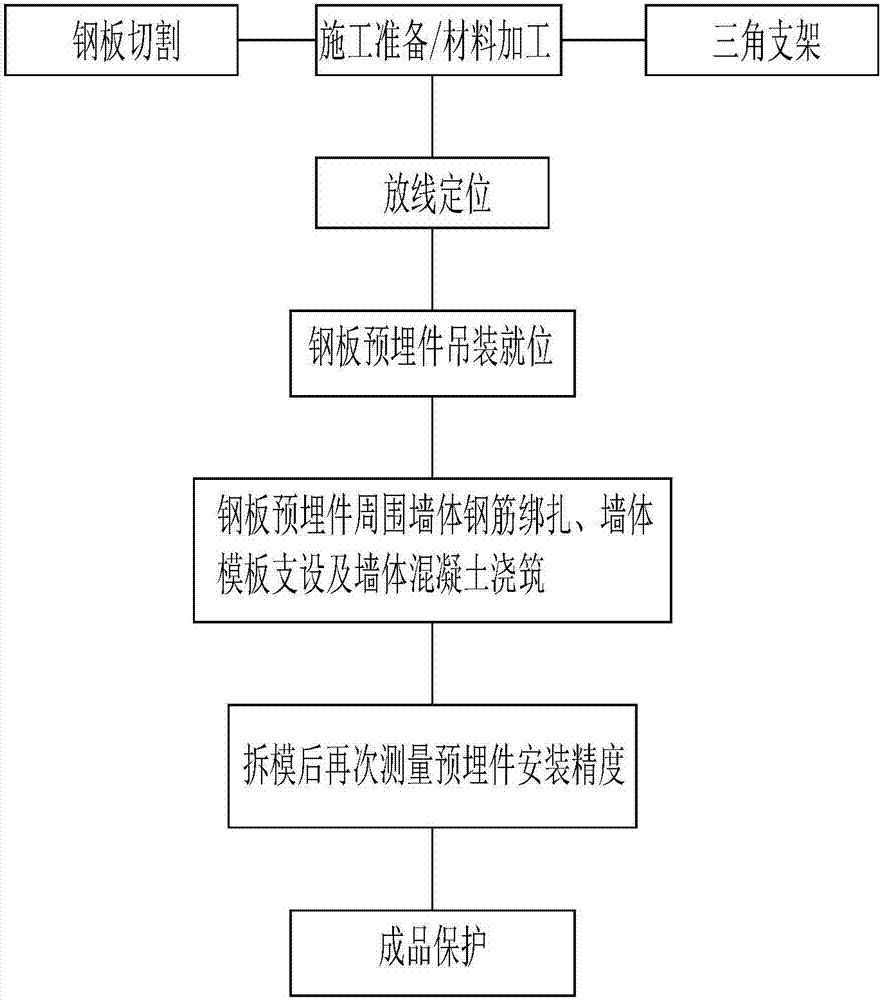

[0020] Such as figure 1 Shown:

[0021] The present invention adopts a construction method of large-scale steel plate pre-embedded parts of the wall, and its technological process is: factory processing and production → setting out and positioning → hoisting of the steel plate pre-embedded parts → welding the triangular steel bar bracket to fix the steel plate → binding the wall reinforcement around the steel plate , Support formwork, concrete pouring of the wall → measure the installation accuracy of the embedded parts again after removing the formwork → product protection.

[0022] The specific process and operation points are as follows:

[0023] 1 Factory processing and production

[0024] According to the design drawings and specification requirements, the steel plate after hot-dip galvanizing treatment is selected, the steel plate is cut by pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com