Formwork reinforcement system with overall pouring construction of L-type short-leg shear wall

A formwork reinforcement and integral pouring technology, which is applied in the field preparation of building components, formwork/formwork/working frame connectors, construction, etc., can solve the problems of low turnover efficiency, increased project cost, fragmented formwork, etc. Achieve the effects of simplified reinforcement methods, easy operation and control, and control of molding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

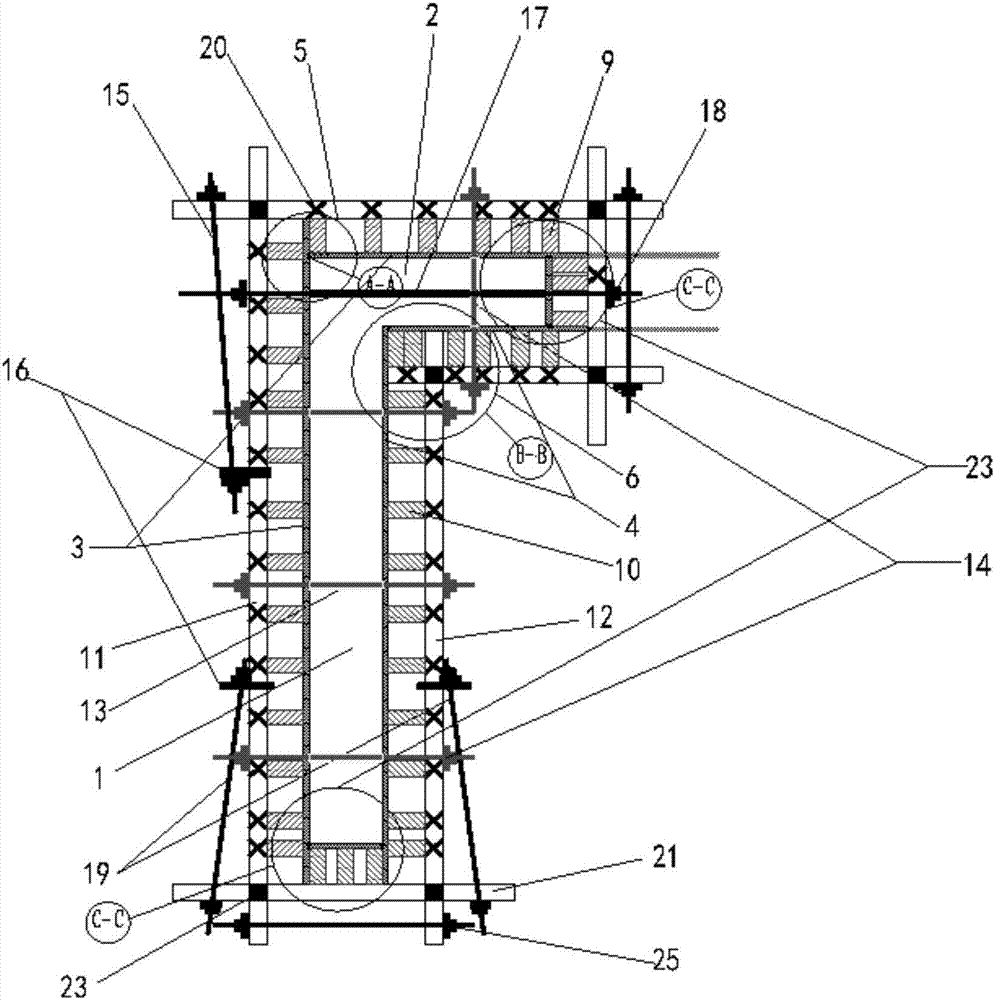

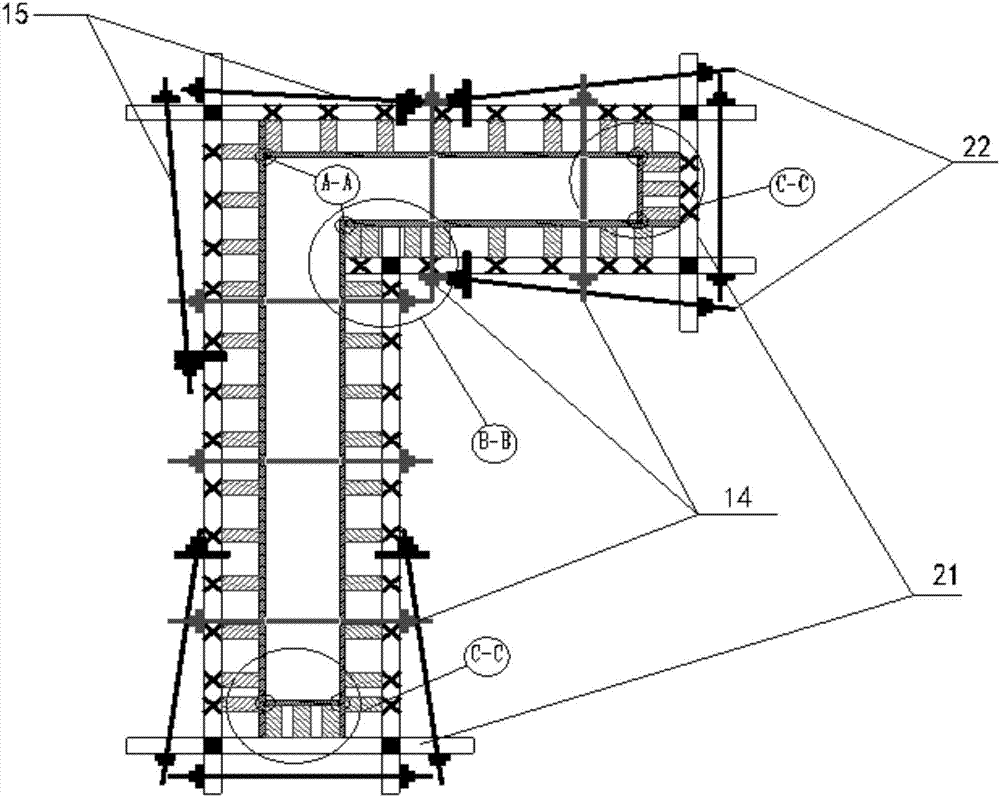

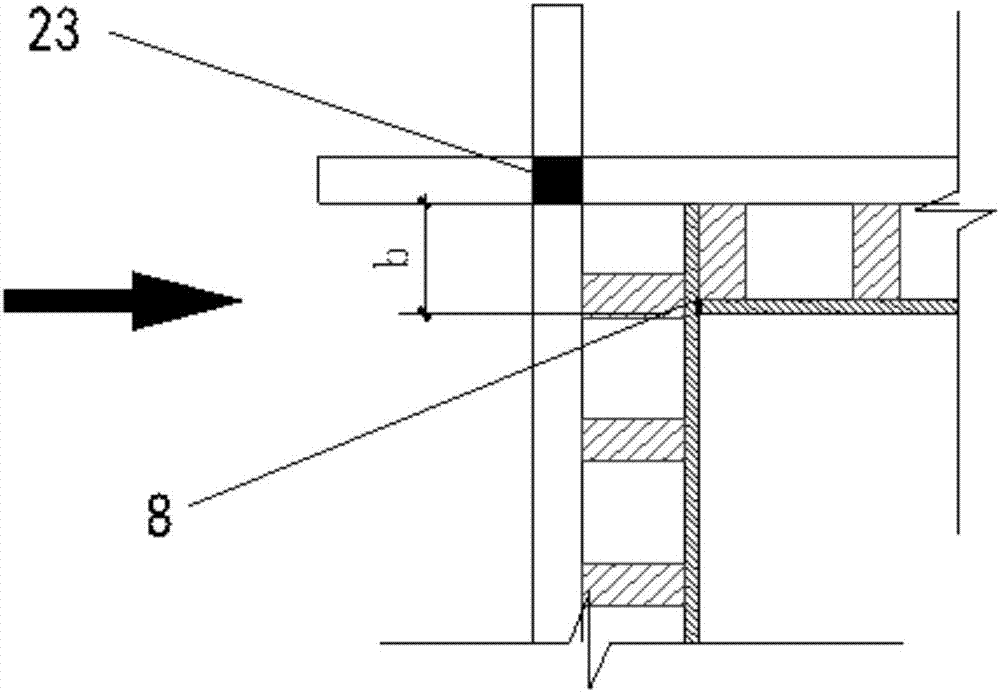

[0013] The present invention is described in detail below in conjunction with accompanying drawing:

[0014] The formwork reinforcement system of the integral pouring construction of the L-shaped short-leg shear wall of the present invention comprises an L-shaped short-leg wall body 1 and an L-shaped short-leg wall top plate 2, and the L-shaped short-leg wall body 1 and the L-shaped short-leg wall The outer side of the wall top plate 2 is provided with an outer wooden plywood formwork 3, and an inner wooden plywood formwork 4 is arranged on the inner side of the L-shaped short limb wall body 1 and the L-shaped short limb wall top plate 2, and an inner wooden plywood formwork 4 is arranged at the upper corner of the outer wooden plywood formwork 3. There is a male corner 5 of the wall, and a female corner 6 of the wall is arranged at the upper corner of the wooden plywood template 4 on the inner side, and an end template 7 is arranged on the end of the L-shaped short limb wall, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com