Double-liner air-conditioner water heating system

An air-conditioning hot water, double liner technology, applied in fluid heaters, lighting and heating equipment, compressors with reversible cycles, etc., can solve the problems of waste of compressor work, inability to produce hot water, and low heating efficiency. Achieve high heating efficiency, reasonable structure, and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

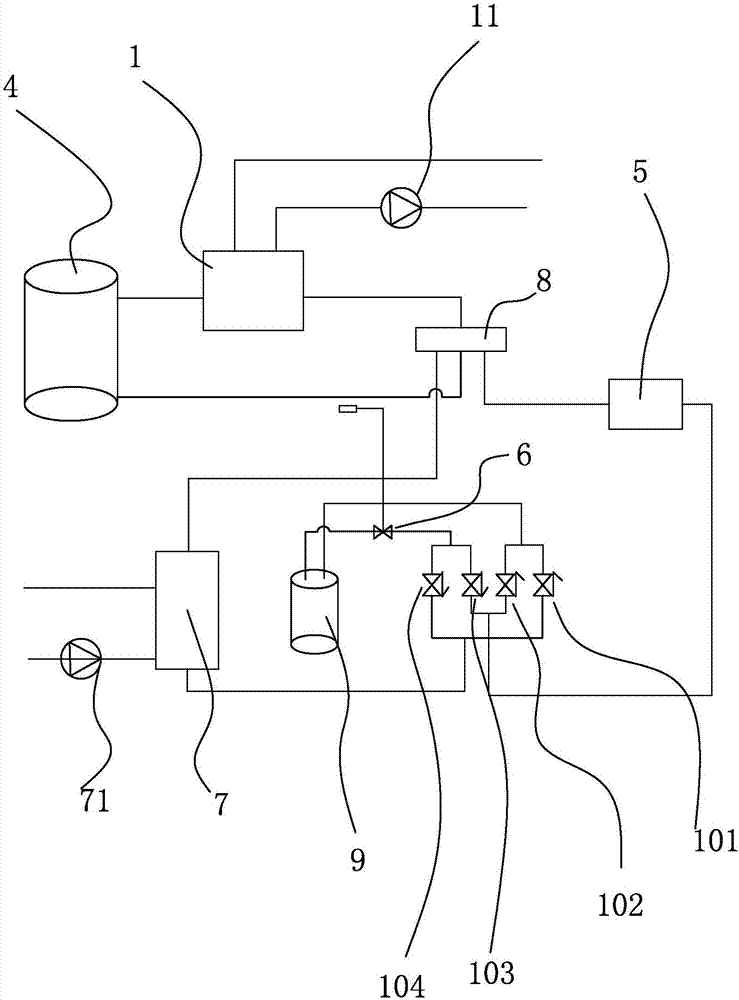

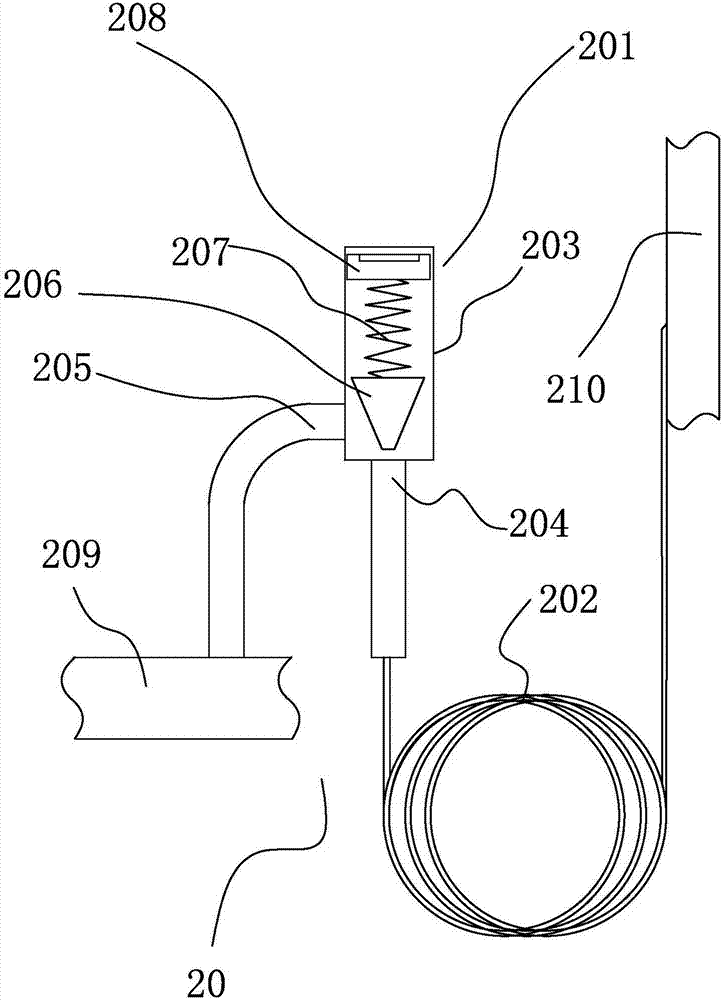

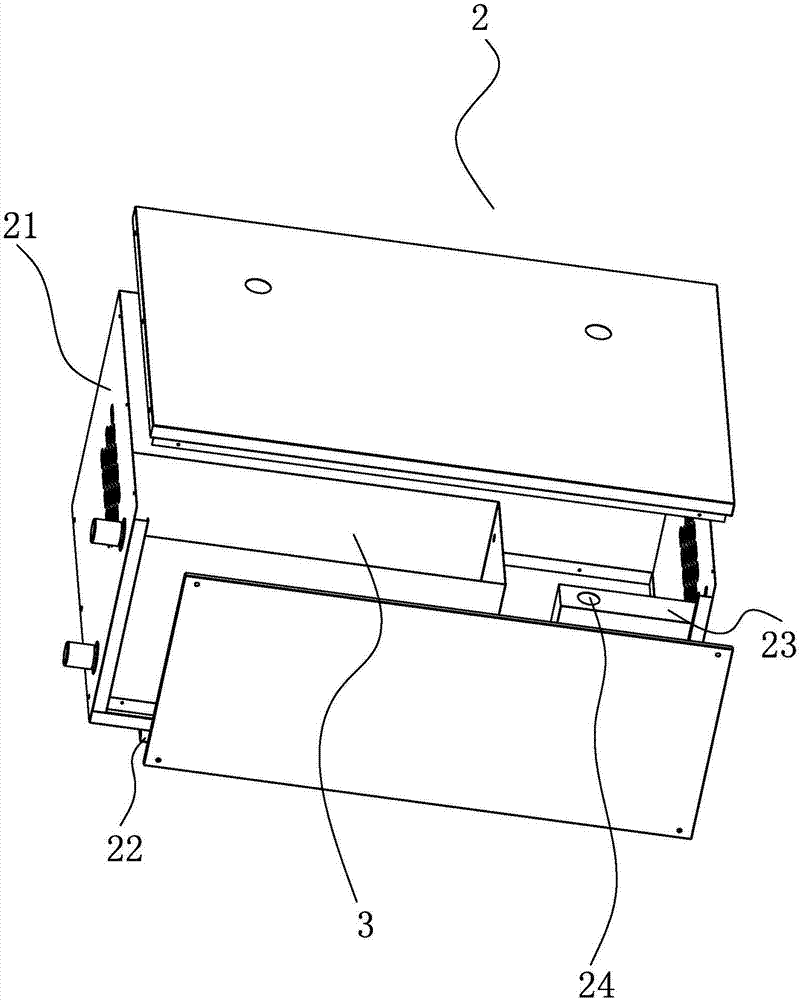

[0017] refer to Figure 1~5, a dual-liner air-conditioning hot water system, including an organic case 2, a condenser 5, a compression device 4, a throttling device 6, an evaporator 7, a one-way valve assembly, an electromagnetic four-way valve 8, a liquid reservoir 9, a replacement Heater 1, pressure control device 20, high-pressure liquid section pipeline 209 and low-pressure liquid section pipeline 210, the compression device is connected to heat exchanger 1, heat exchanger 1 is connected to electromagnetic four-way valve 8, and electromagnetic four-way valve 8 is respectively connected to condensation The device 5, the compression device 4, and the evaporator 7 are connected, and the one-way valve assembly is connected with the condenser 5, the evaporator 7, the liquid reservoir 9, and the throttling device 6 respectively, and the one-way valve assembly includes a first one-way valve 101, The second one-way valve 102, the third one-way valve 103 and the fourth one-way valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com