Encoder and installation method thereof

An encoder and grating technology, which is applied in the field of encoder structure design, can solve problems such as poor reliability of the encoder, and achieve the effects of improving installation efficiency, good protection, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

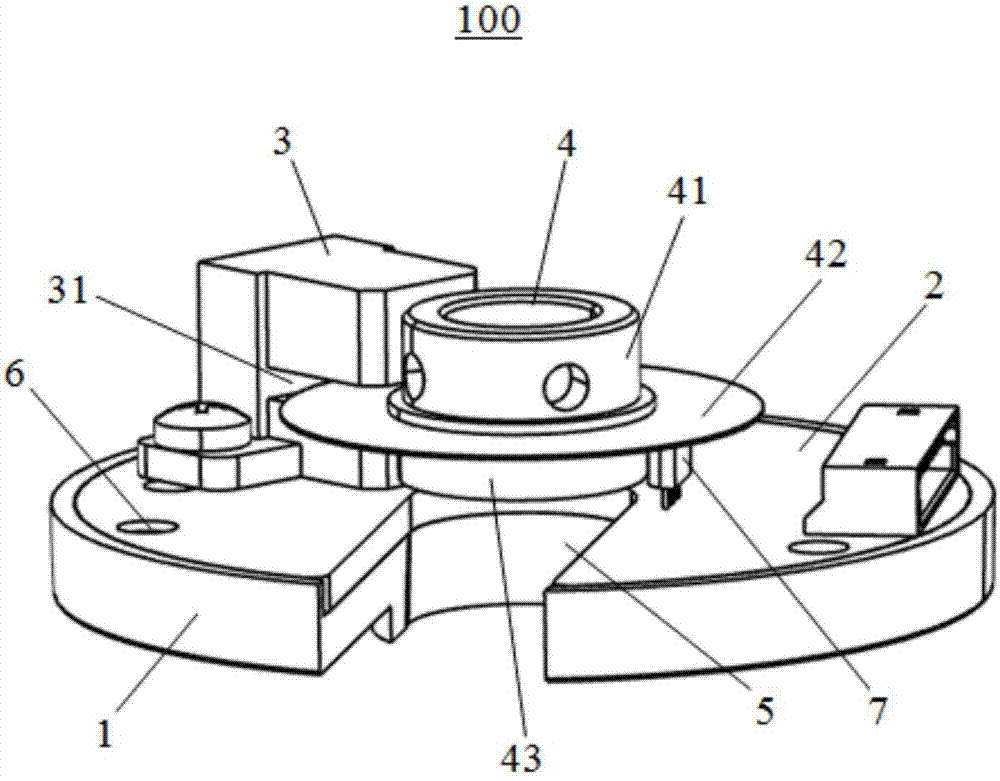

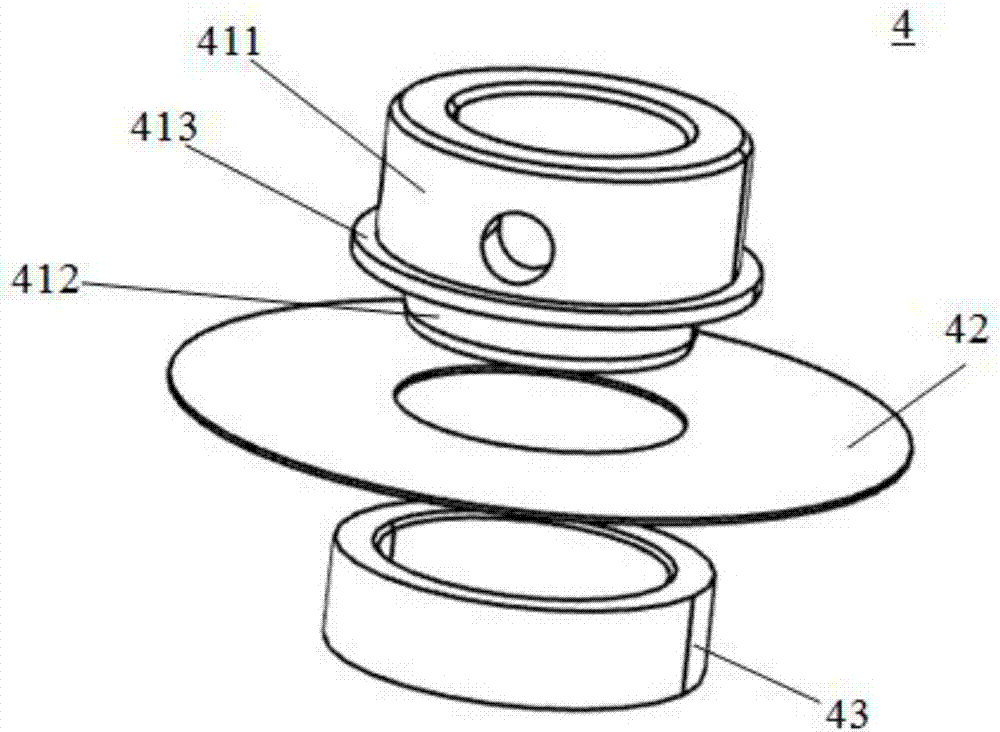

[0038] Please refer to Figure 1-Figure 2 , the present embodiment is an encoder 100, which includes an encoder bracket 1, a PCB circuit board 2 embedded in the encoder bracket 1, a reading head 3 electrically connected to the PCB circuit board 2, and a motor rotating The rotating assembly 4 on the shaft, the rotating assembly 4 is assembled by the grating bracket 41, the grating 42 and the multi-pole magnetic ring 43, the multi-pole magnetic ring 43 is sleeved on the lower end of the grating bracket 41, and the grating 42 is sleeved on the grating bracket 41 and located between the grating support 41 and the multi-pole magnetic ring 43 .

[0039] The side surface of the reading head 3 is provided with a groove 31 for accommodating the grating 42. The grating 42 rotates together with the motor shaft. Whenever the grating 42 passes through the groove 31, the reading head 3 records, thereby controlling the rotation of the motor.

[0040] The encoder bracket 1 and the PCB circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com