Single-side heating multi-slit hemostatic needle

A technology of gap and insulating medium, applied in the field of medical devices, can solve the problems of complicated operation process, slow excision time, and heavy bleeding, so as to avoid indiscriminate injury, reduce the degree of carbonization and scab, and reduce the bleeding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

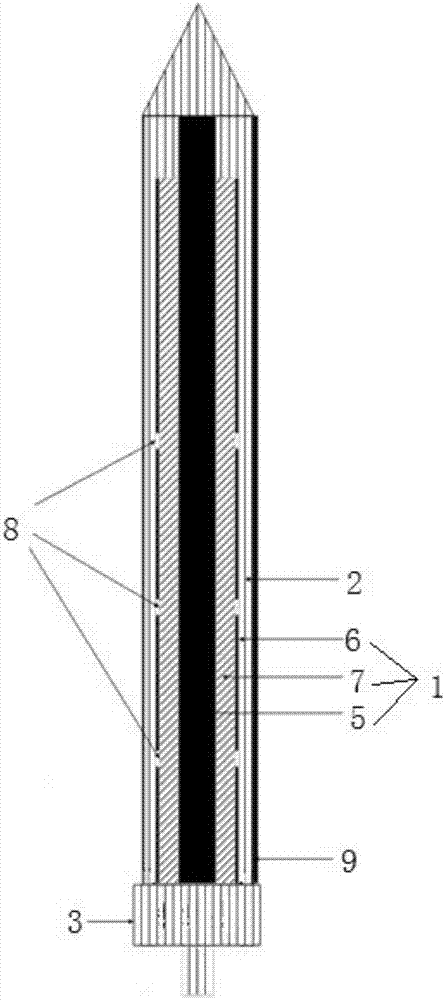

[0030] Such as figure 1 As shown, the unilaterally heated multi-slit hemostatic needle disclosed in this embodiment includes a coaxial multi-slit electromagnetic main radiator 1 and an insulating dielectric body 2. The insulating dielectric body 2 has a multi-slit electromagnetic main radiator 1. The cavity, the multi-slot electromagnetic main radiator 1 is arranged in the cavity, the multi-slot electromagnetic main radiator 1 includes an inner conductor 5 and an outer conductor 6, the outer conductor 6 is a hollow cylinder, the inner conductor 5 is preferably a metal conductor column, and the outer conductor 6. The metal conductor thin layer structure is preferred. The inner conductor 5 is arranged in the outer conductor 6. The front end of the inner conductor 5 exceeds the outer conductor 6. An insulating medium layer 7 is filled between the inner conductor 5 and the outer conductor 6. The material of the insulating medium layer 7 is preferably polyethylene. Outer conductor...

Embodiment 2

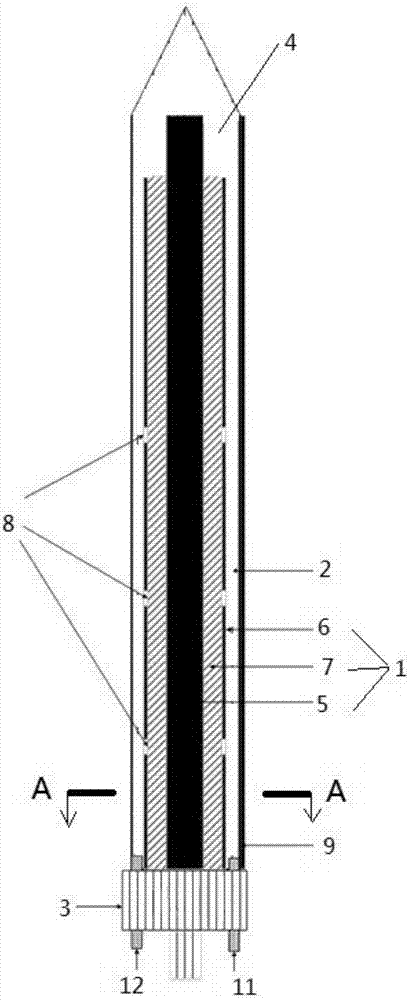

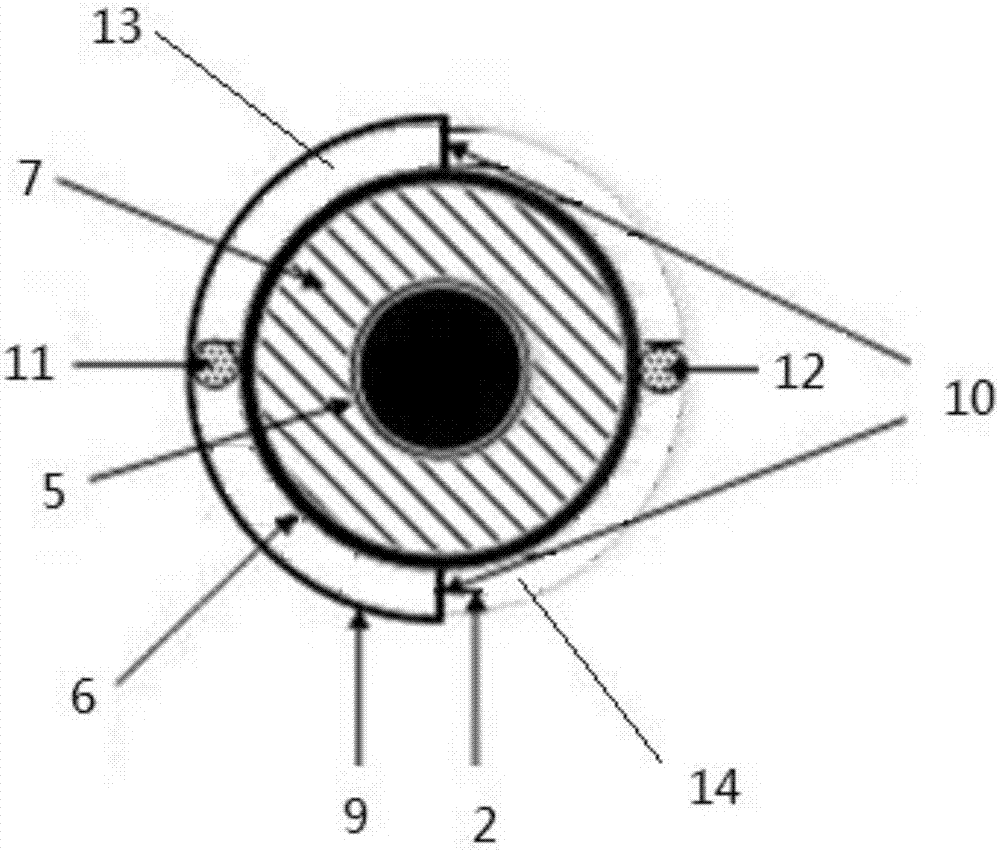

[0036] The difference between this embodiment and embodiment 1 is: as figure 2 , 3 As shown, a cooling chamber 4 is provided in the insulating medium body 2, and the multi-slit electromagnetic main radiator 1 is located inside the cooling chamber 4. The cooling chamber 4 includes a first chamber 13 and a second chamber 14. The first chamber The chamber 13 and the second chamber 14 are axially arranged, the rear end of the first chamber 13 communicates with the water inlet pipe 11, the rear end of the second chamber 14 communicates with the water outlet pipe 12, and the front end of the first chamber 13 communicates with the second chamber. The front end of the chamber 14 communicates. The cooling chamber provided in the invention can effectively reduce the temperature of the needle body and reduce the degree of carbonization and scabbing of objects on the contact surface.

[0037] For example, the insulating dielectric body 2 is an inner and outer double-layer structure, an...

Embodiment 3

[0039]The difference between this embodiment and Embodiment 1 or 2 is that there are three slots 8, namely the first slot, the second slot and the third slot. The third slot is located at the front end of the second slot, and the second slot is located at the front end of the first slot. Wherein, the width of the first slit is 3 mm, the width of the second slit is 2 mm, and the width of the third slit is 3 mm. The distance between the first slit and the second slit is 30mm, the distance between the second slit and the third slit is 20mm, and the distance between the third slit and the front end of the outer conductor 6 is 27mm. The length of the insulating dielectric body 2 is 125 mm, extending 125 mm from the connecting base 3 to the front end, and the front end of the inner conductor 5 is 63-5 mm beyond the outer conductor. The length of the metal retainer 9 is equal to the length of the inner conductor 5 , and the metal retainer 9 extends from the connecting seat 3 to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com