A kind of unequal thickness ferrite magnetic tile and its preparation method

A ferrite magnetic and unequal technology, which is applied in the direction of manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of low surface magnetism at the center point of the inner arc and uneven surface magnetism of the inner arc working surface. Achieve smooth surface magnetic waveform, increase surface magnetic induction intensity, and improve the effect of surface magnetic distribution waveform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 (parallel orientation):

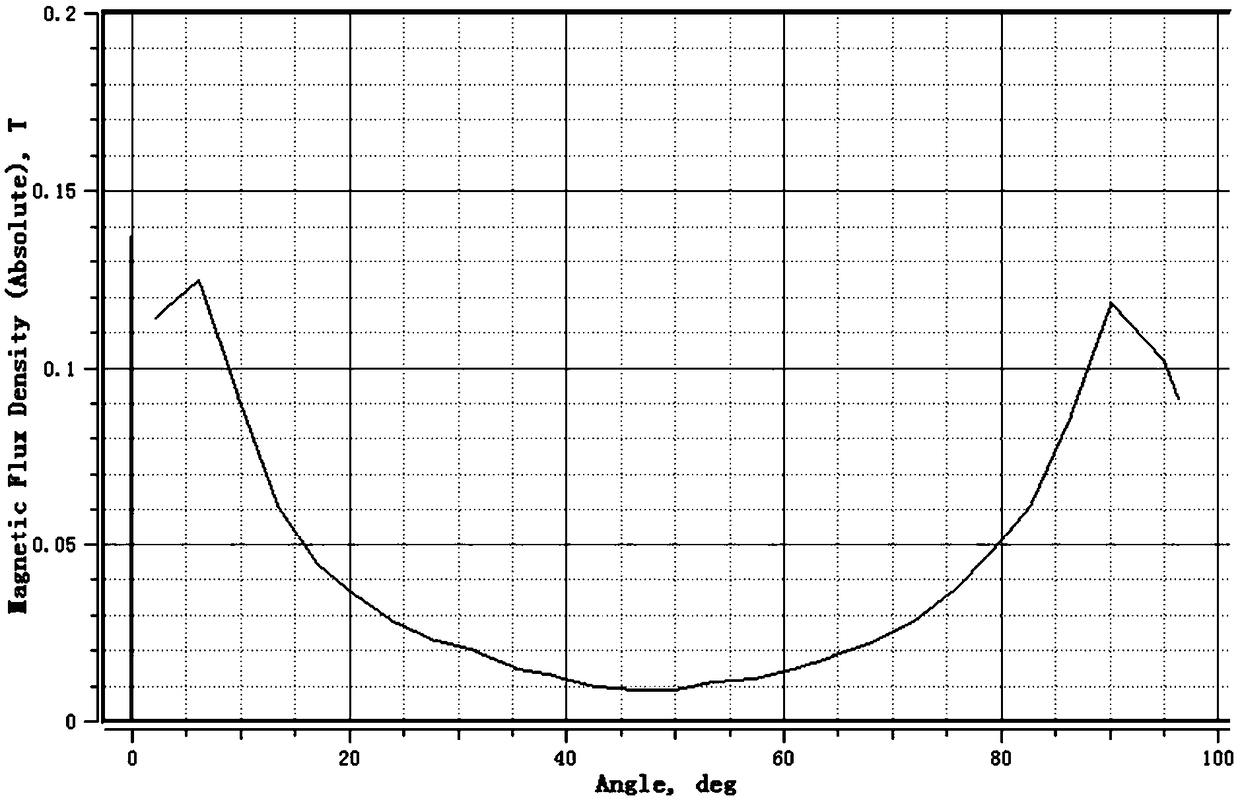

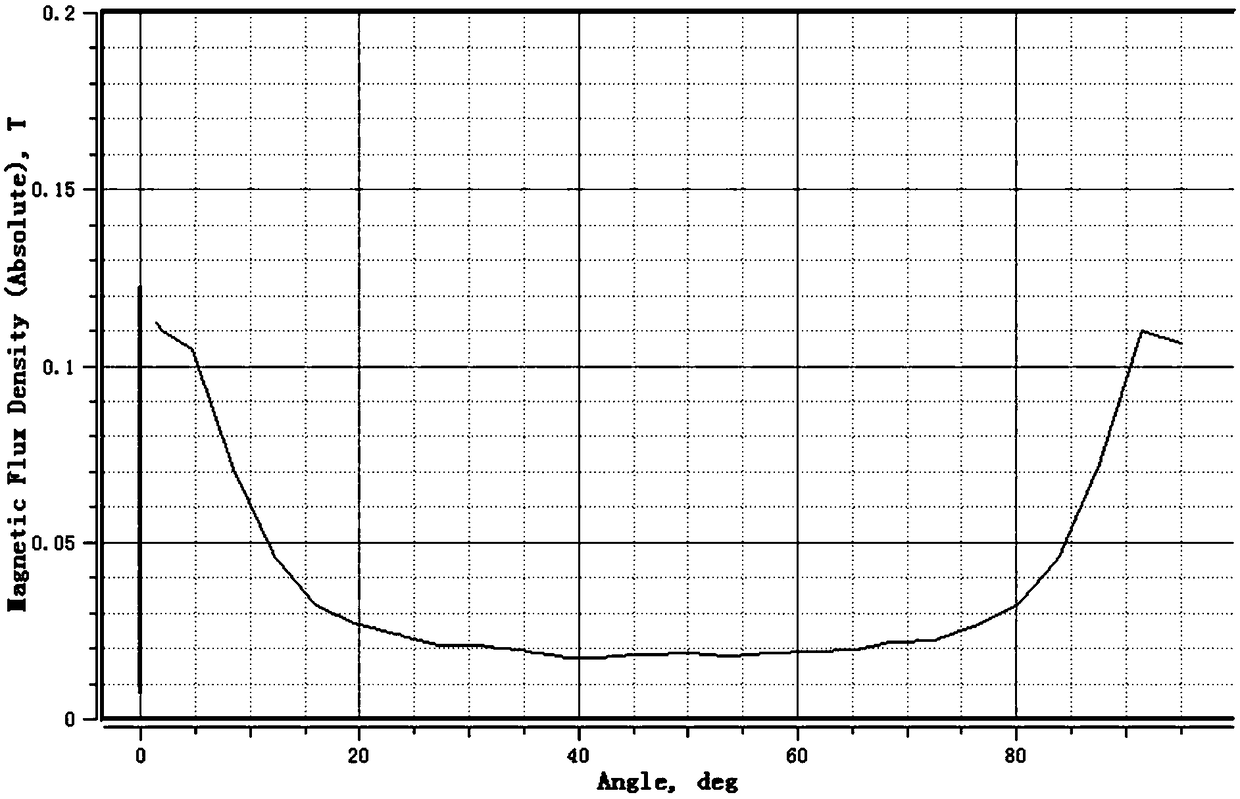

[0031] The conventional process of parallel orientation magnetic field is used to prepare 10 conventional ferrite magnet tiles of the same thickness of the above specifications, and then 5 ferrite magnets of equal thickness are processed by the grinding method to prepare the ferrite magnets of different thickness of the above specifications , Take 3 each of the above two types of magnet tiles and measure the magnetism at different positions of the inner arc centerline, and draw the magnetism distribution curve. among them: figure 2 It is the magnetic test curve diagram of the inner arc centerline of the conventional magnetic tile in Example 1; image 3 It is the magnetic test curve diagram of the inner arc center line of the unequal-thickness magnet tile in Example 1. Table 2 is a comparison table of the magnetism of the inner arc center point of the two specifications of the magnetic tile in Example 1.

[0032] Table 2 Example 1 Compari...

Embodiment 2

[0035] Example 2 (Radiation orientation):

[0036] The conventional process of radiation orientation magnetic field is used to prepare 10 conventional ferrite magnet tiles of the same thickness of the above specifications, and then 5 ferrite magnets of equal thickness are processed by the grinding method to prepare the ferrite magnets of different thickness of the above specifications , Take 3 each of the above two types of magnet tiles and measure the magnetism at different positions of the inner arc centerline, and draw the magnetism distribution curve. among them: Figure 4 It is the magnetic test curve diagram of the inner arc center line of the conventional magnetic tile in Example 2; Figure 5 It is the magnetic test curve diagram of the inner arc center line of the unequal-thickness magnet tile in Example 2. Table 3 is a comparison table of the magnetism of the inner arc center point of the two specifications of the magnetic tile in Example 2.

[0037] Table 3 Example 2 Co...

Embodiment 3

[0040] Example 3 (molding method):

[0041] According to the specifications of the above-mentioned unequal-thickness magnet tiles, respectively design the forming molds for parallel orientation and radiation orientation, and prepare 5 unequal-thickness magnet tiles of parallel orientation and radiation orientation according to the magnetic tile production process, and test the inner arc center after magnetization The point table magnetism is shown in Table 4 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com