Cement stable regeneration aggregate gravel proportioning design method

A recycled aggregate and cement stabilization technology, applied in the direction of ratio control, instrument, control/regulation system, etc., can solve the problems of oblique shear force and vibration, low strength, poor test reproducibility, etc., to reduce drying shrinkage Cracking, reduced possibility, good effect of on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] An embodiment of the cement-stabilized recycled aggregate gravel ratio design method of the present invention, the method described in this embodiment includes the following steps:

[0041] 1. Grading design:

[0042] First of all, according to the "Technical Rules for Road Pavement Base Construction" (JTG / T F20-2015), the synthetic gradation of mineral materials is selected, as shown in Table 1:

[0043] Table 1 Recommended grading range of cement-stabilized graded crushed stone or gravel

[0044]

[0045] 2. Select the amount of cement and water

[0046] Material technical index requirements are as follows:

[0047] (1) Water, cement

[0048] The water used should meet the specification "Concrete Mixing Water Standard", and the cement should also meet the requirements of the specification "Technical Rules for Road Pavement Base Construction" (JTG / T F20-2015). The initial setting time of the cement used should not exceed 3 hours, and the final setting time shoul...

Embodiment 2

[0089] An embodiment of the cement-stabilized recycled aggregate gravel ratio design method of the present invention, the method described in this embodiment is the same except that the number of settings of cement consumption is different from that of Embodiment 1, and includes the following steps:

[0090] 1. Determination of mineral gradation:

[0091] Summarize the best cement content and the ratio of each aggregate. The amount of water added should be appropriately increased by 1 to 2%; we have made several test pieces of cement dosage, and now we take 3 cement dosages as representatives; they are 3%, 5%, and 7% respectively. First determine the mineral material grading of each cement as shown in Tables 5 to 7:

[0092] Table 5 The mass percentage of 3% cement content passing through the sieve hole

[0093] particle size 31.5 26.5 19 16 13.2 9.5 4.75 2.36 1.18 0.6 0.3 0.15 0.075 Specification online 100 92.4 83.6 75.2 68.1 61.5 44.5 3...

Embodiment 3

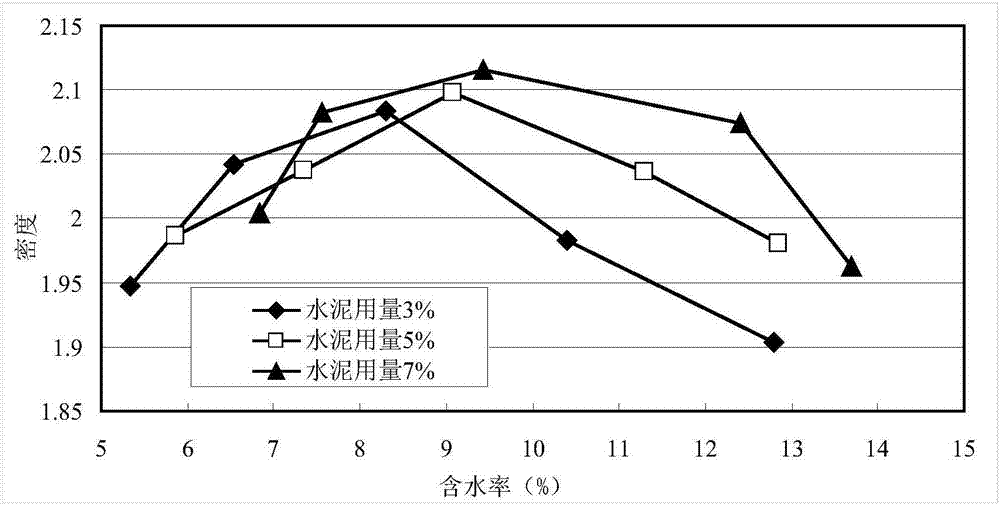

[0104] In this embodiment, the maximum dry density-moisture content curve of the test piece in the method of the present invention is studied and analyzed. Such as figure 1 as shown, figure 1 There are three curves in total, representing the cement content of 3%, 5%, and 7% respectively. Each curve has 5 points in total. The ordinate is the density, and the abscissa is the water content at the corresponding density. The specimen is compacted 10 times in a row The accumulation of height changes of no more than 1mm is the standard for stopping compaction.

[0105] Depend on figure 1 It can be seen that the density of recycled aggregate cement stabilized macadam under the three kinds of cement dosage increases firstly and then decreases with the increase of water consumption, and the maximum dry density of the material is 2.084g / cm2 under the cement dosage of 3%. 3 , corresponding to the optimal water content of 8.29%; the maximum dry density of the material is 2.097g / cm when ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry density | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com