Method for preparing active ginsenoside

A technology of ginsenoside and ginseng is applied in the field of preparation of active ginsenoside and can solve problems such as unfavorable strain survival and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

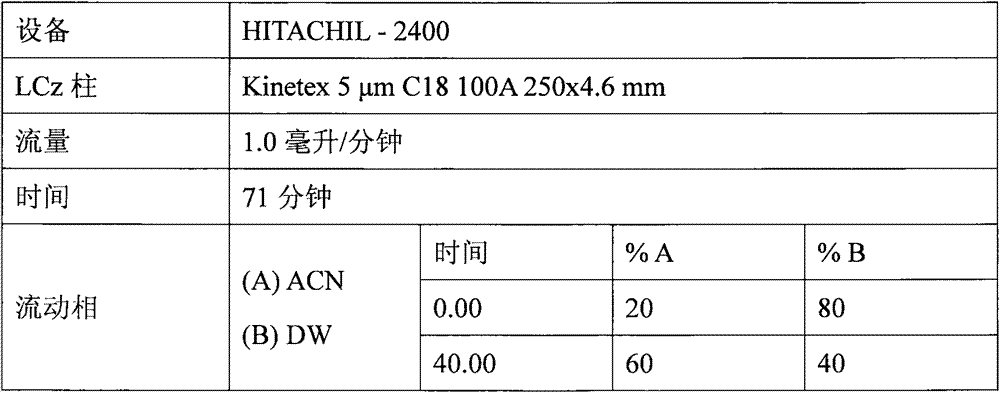

Method used

Image

Examples

Embodiment 1

[0035] The preparation of embodiment 1 active PPD

[0036] Load the ginseng into the perforated rack inside the reaction chamber. Through the automatic temperature and humidity control device, steam is introduced into the reaction chamber, the air is removed, and heat treatment is performed directly by steam, and the steam pressure is 1.1kg / cm 2 . Keep the temperature at 121°C for 10 minutes to remove excess water from ginseng.

[0037] Cool the heat-treated ginseng to below 90°C, open the exhaust valve to inject air, and continue to repeat the above operation twice.

[0038] Grinding the heat-treated ginseng into particles with a diameter of no more than 1 mm, adding 80 vol% ethanol after drying, and heating to fully extract ginsenosides. Filter out solid particles above 500 microns through filter paper, and collect the ethanol solution through the filter paper, which is called heat-treated saponin ethanol solution.

[0039] Concentrate the heat-treated saponin ethanol so...

Embodiment 2

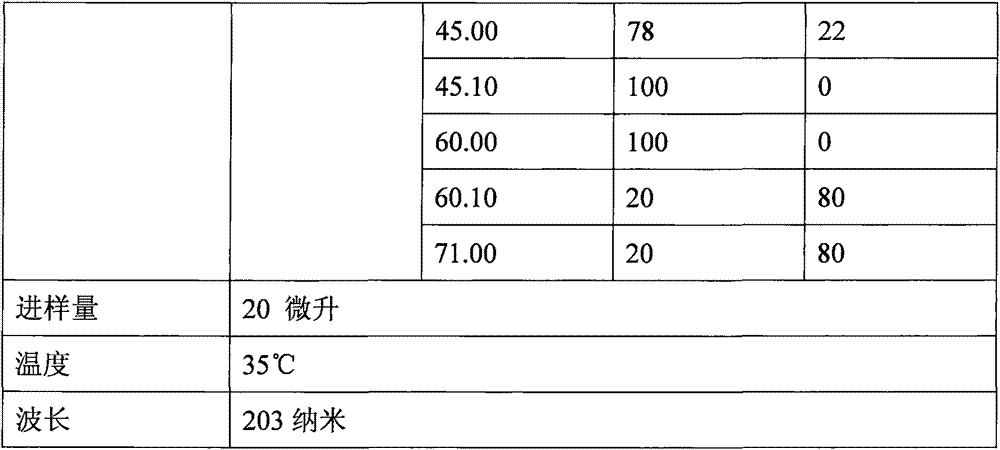

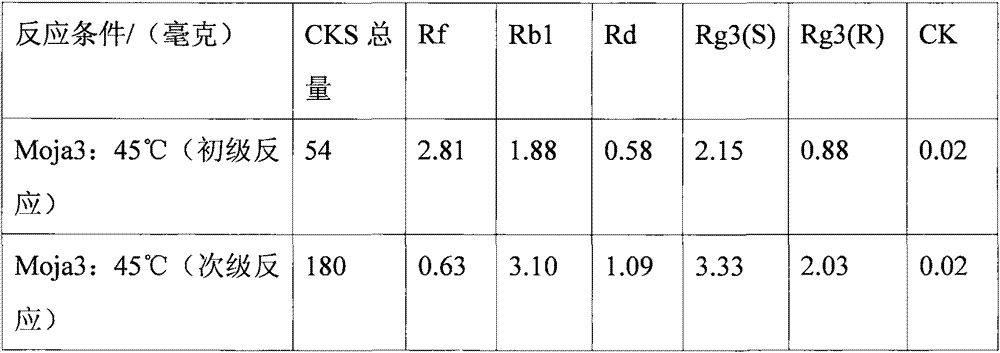

[0040] Example 2 Moja-3 strain fermentation (45 ℃) produces active saponin

[0041] Get the ginsenosides containing active PPDs such as Rg3 prepared in Example 1, after drying, get 24 grams for the following experiments.

[0042] First, the Mojia-3 strain was cultivated in Tryptic Soy Broth (TSB) at a temperature of 45° C. for not less than 16 hours. Take 100 ml of culture solution and add it to 1000 ml of fresh TBS for subculture, and incubate at 45°C for 60 minutes. After the incubation was completed, 100 ml of 10% (w / v) active PPD suspension was added with a hose pump at a rate of 20 ml / min. Cultivate again at 45° C. for 6 hours to obtain CKS solution.

[0043] The CKS solution was centrifuged to obtain the supernatant, which was called solution A. The precipitate after centrifugation was pooled and redissolved in a small amount of ethanol. Filter, take the filtrate, and concentrate to obtain a CKS solution with a higher concentration. The CKS solution was freeze-dried...

Embodiment 3

[0045] Example 3 Bp-2 fermented (55°C) to produce active saponins

[0046] Get the ginsenosides containing active PPDs such as Rg3 prepared in Example 1, after drying, get 24 grams for the following experiments.

[0047] First, culture the Bp-2 strain with tryptic soybean broth (TSB) at a temperature of 45° C. for not less than 16 hours. Take 100 ml of culture solution and add it to 1000 ml of fresh TBS for subculture, and incubate at 55°C for 60 minutes. After the incubation was completed, 100 ml of 10% (w / v) active PPD suspension was added with a hose pump at a rate of 20 ml / min. Cultivate again at 55° C. for 6 hours to obtain CKS solution.

[0048] The CKS solution was centrifuged to obtain a supernatant, called solution B. Dissolve the precipitate with a small amount of ethanol, filter, take the filtrate, and concentrate to obtain a CKS solution with a higher concentration. The CKS solution was freeze-dried to yield 0.0645 g of CKS (CKS primary reaction).

[0049] Con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com