System and method for verifying functions of starting and stopping reactor of high-temperature gas cooled reactor

A high-temperature gas-cooled reactor and equipment function technology, applied in the field of nuclear power, can solve problems such as unsolvable, reactor emergency shutdown, and inability to accurately verify actual functions, so as to reduce abnormal failures, ensure reliability and safety, and save trial runs The effect of duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

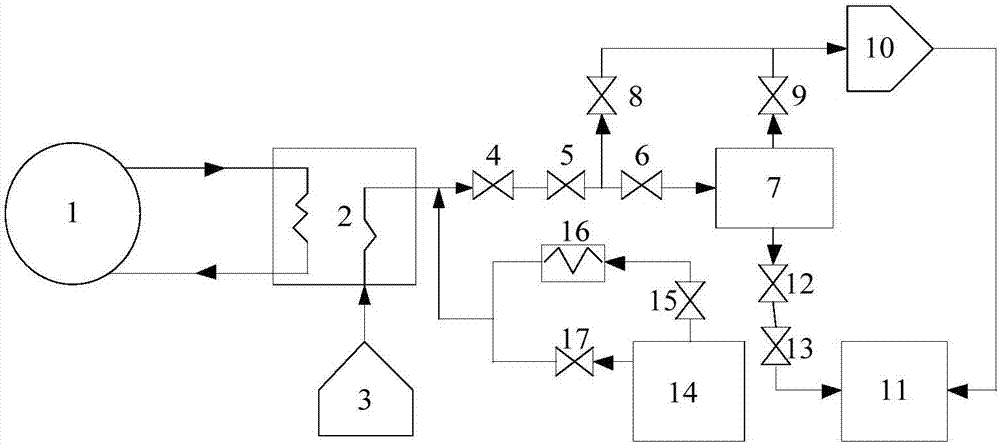

[0045] This embodiment takes a high-temperature gas-cooled reactor nuclear power unit in China as an example. The nuclear power plant is mainly composed of two modular high-temperature gas-cooled reactors and a turbogenerator set. The steam parameters of the secondary circuit outlet of the island steam generator 2 are up to 5.0MPa and 400°C, so as to meet the start-up requirements of the conventional island steam turbine; during the shutdown process of the reactor 1, the start-up and shutdown equipment ensures the cooling of the steam generator 2 and the reactor 1; the unit can The external steam used is provided by an auxiliary boiler 14, which has a steam superheater 16, which can continuously provide two kinds of steam sources with different parameters, that is, the rated parameters are 20t / h, 8.0MPa and 294°C For saturated steam and superheated steam with rated parameters of 10t / h, 8.0MPa and 450°C, the start-up function verification process is as follows:

[0046] 1a) Slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com