Chemical and mechanical polishing equipment

A chemical machinery and equipment technology, applied in the field of chemical mechanical polishing equipment, can solve problems such as substandard quality of polishing liquid, achieve good polishing effect, eliminate eddy current phenomenon, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

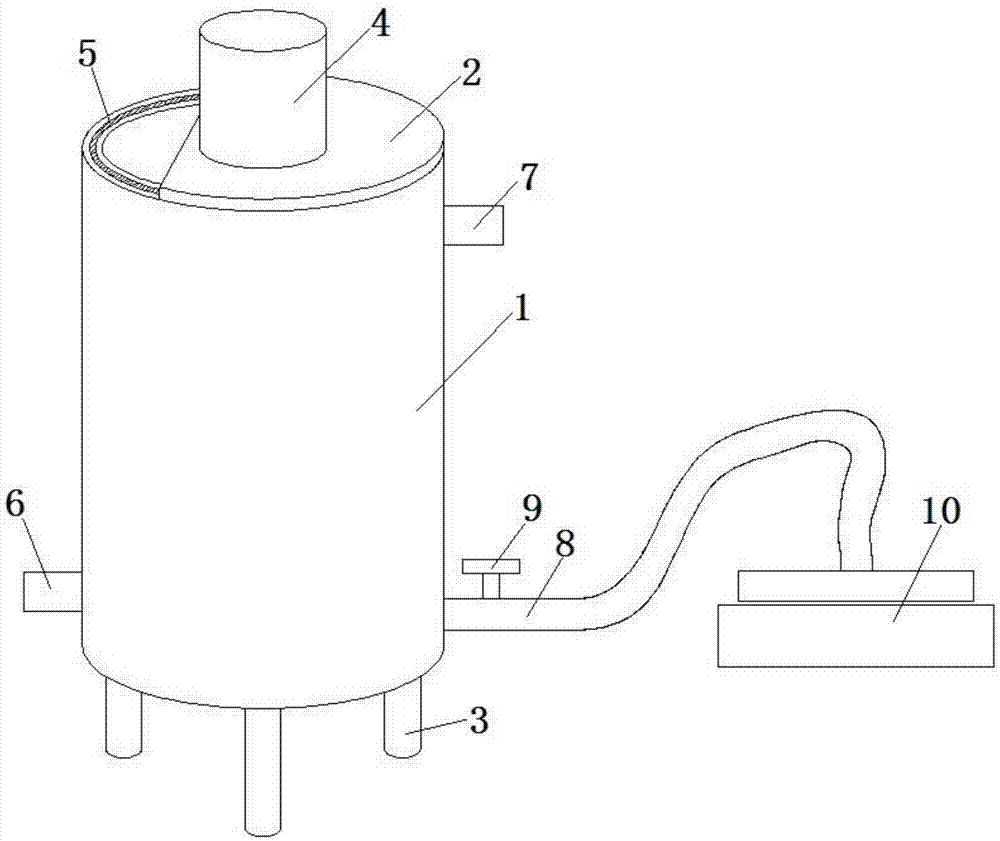

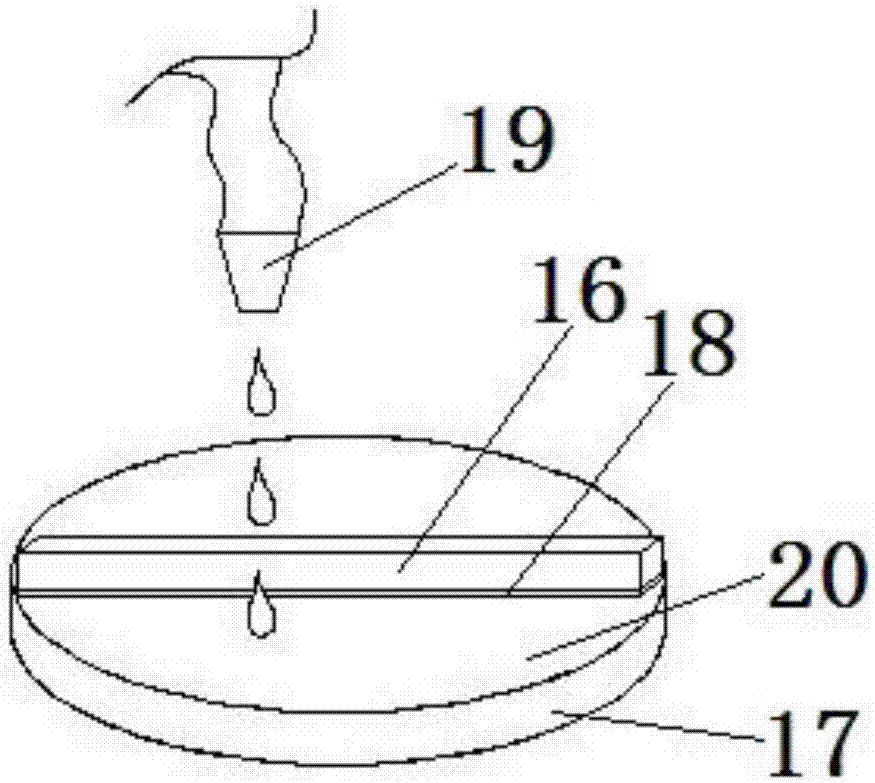

[0031] refer to Figure 1-4 , a kind of chemical mechanical polishing equipment, comprises the batching bucket 1 that is used for preparing polishing liquid and the polisher 10 that is used for polishing wafer 20, and described polisher 10 is connected with batching bucket 1 through conveying pipe 8, and batching bucket 1 completes After preparing the polishing liquid, the polishing liquid is transported to the polisher 10 through the delivery pipe 8, and then the wafer 20 is polished.

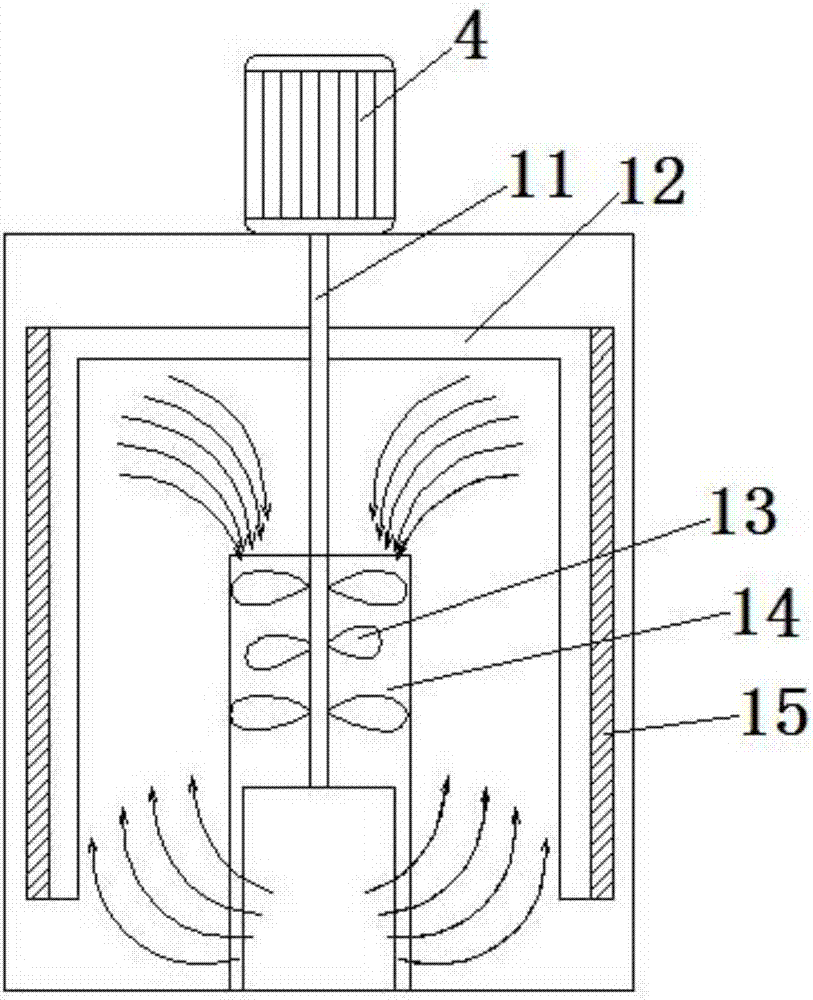

[0032] The bottom of the batching barrel 1 is provided with a bracket 3, and the top is provided with a bung 2. The bung 2 is provided with a feeding opening, and the lower end of the bucket 1 is provided with a discharge opening, and a valve 9 is provided at the discharge opening. Described batching barrel 1 is provided with stirring device, and stirring device comprises stirring shaft 11 and the stirring blade 13 that is fixed on the stirring shaft 11, and described stirring blade 13 quantit...

Embodiment 2

[0037] A stirring paddle 12 is also fixed on the stirring shaft 11 , the stirring paddle 12 is an inverted U shape, and the stirring paddle 12 can stir the materials outside the central cylinder 14 . The side of described stirring paddle 12 is fixed with the bucket wall scraper 15 that vertically arranges, and the distance between the side of bucket wall scraper 15 and the inner wall of batching bucket 1 is 0.2cm, when stirring work, bucket wall scraper 15 rotates with stirring shaft 11 , to scrape off the material adhered to the inner wall of the batching barrel 1, so as to achieve the purpose of cleaning the barrel wall.

Embodiment 3

[0039]The motor 4 is vertically fixed on the surface of the center of the bung 2 by four screws, so that it can be easily disassembled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com