Litchi essence, preparation method thereof, and application thereof to cigarette

A technology of lychee essence and lychee, which is applied in the fields of application, essential oil/spice, tobacco, etc., can solve the problems that have not been reported, and achieve the effect of low cost, simple operation, and improved sensory comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

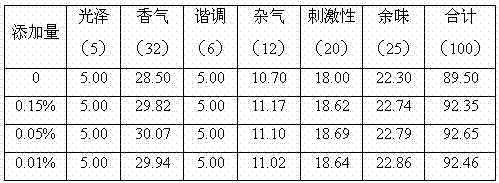

Image

Examples

Embodiment 1

[0024] A preparation method of lychee essence, specifically comprising the steps of:

[0025] (1) Pretreatment: Select fresh lychees with natural color, ripe fruit, and no pests and diseases, dry them in an oven at 60°C, remove the peel and core, and take out the pulp;

[0026] (2) Crushing and beating: According to the water: litchi pulp (m / m) = 1:1, use a high-speed tissue masher (speed 12000rpm / min) to beat for 5 minutes to obtain litchi pulp;

[0027] (3) Filtration under reduced pressure: Pour the obtained lychee pulp on the filter paper of the Buchner funnel, and filter under reduced pressure to obtain the filtrate;

[0028] (4) Yeast fermentation: add active dry yeast to the filtrate (the amount of active dry yeast added is 0.2% of the mass of the filtrate), and incubate at a constant temperature of 35°C for 2 hours to obtain a culture medium;

[0029] (5) Baking at high temperature: put the culture medium in an oven, evaporate the water at 70°C, and bake at 130°C for ...

Embodiment 2

[0036] A preparation method of lychee essence, specifically comprising the steps of:

[0037] (1) Pretreatment: Select fresh lychees with natural color, ripe fruit, and no pests and diseases, dry them in an oven at 50°C, remove the peel and core, and take out the pulp;

[0038] (2) Crushing and beating: According to the water: litchi pulp (m / m) = 1.5:1, use a high-speed tissue masher (rotating speed 10000rpm / min) to beat for 10 minutes to obtain litchi pulp;

[0039] (3) Filtration under reduced pressure: Pour the obtained lychee pulp on the filter paper of the Buchner funnel, and filter under reduced pressure to obtain the filtrate;

[0040] (4) Yeast fermentation: add active dry yeast to the filtrate (the amount of active dry yeast added is 0.4% of the filtrate mass), and incubate at a constant temperature of 45°C for 1 hour to obtain a culture solution;

[0041] (5) Baking at high temperature: put the culture medium in an oven, evaporate the water at 80°C, and bake at 150°...

Embodiment 3

[0048] A preparation method of lychee essence, specifically comprising the steps of:

[0049] (1) Pretreatment: Select fresh lychees with natural color, ripe fruit, and no pests and diseases, dry them in an oven at 55°C, remove the peel and core, and take out the pulp;

[0050] (2) Crushing and beating: according to water: lychee pulp (m / m) = 2:1, use a high-speed tissue masher (speed 11000rpm / min) to beat for 15 minutes to obtain lychee pulp;

[0051] (3) Filtration under reduced pressure: Pour the obtained lychee pulp on the filter paper of the Buchner funnel, and filter under reduced pressure to obtain the filtrate;

[0052] (4) Yeast fermentation: add active dry yeast to the filtrate (the amount of active dry yeast added is 0.1% of the filtrate mass), and incubate at 40°C for 3 hours to obtain a culture solution;

[0053] (5) Baking at high temperature: put the culture medium in an oven, evaporate the water at 60°C, and bake at 110°C for 4 hours to obtain the aroma substa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com