Cotton collection bucket of disc type plucker

The technology of a disc grabbing machine and a cotton hopper is applied in the field of cotton collection hoppers, which can solve the problems of clogging the cotton hopper with cotton lumps, deal with mechanical damage, trouble in recycling iron scraps, etc., so as to reduce the probability of clogging, simplify the operation and operation handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

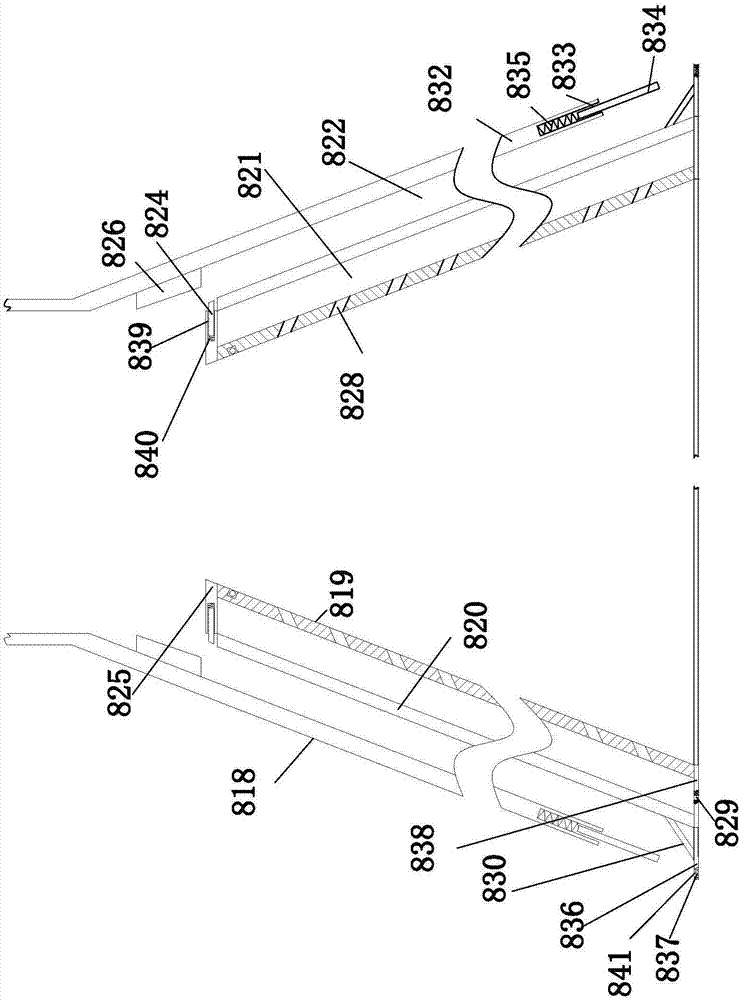

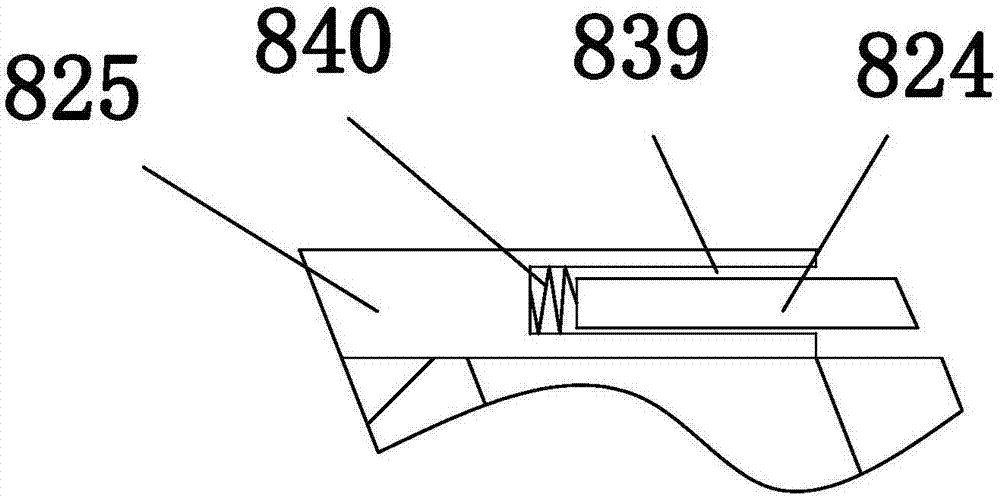

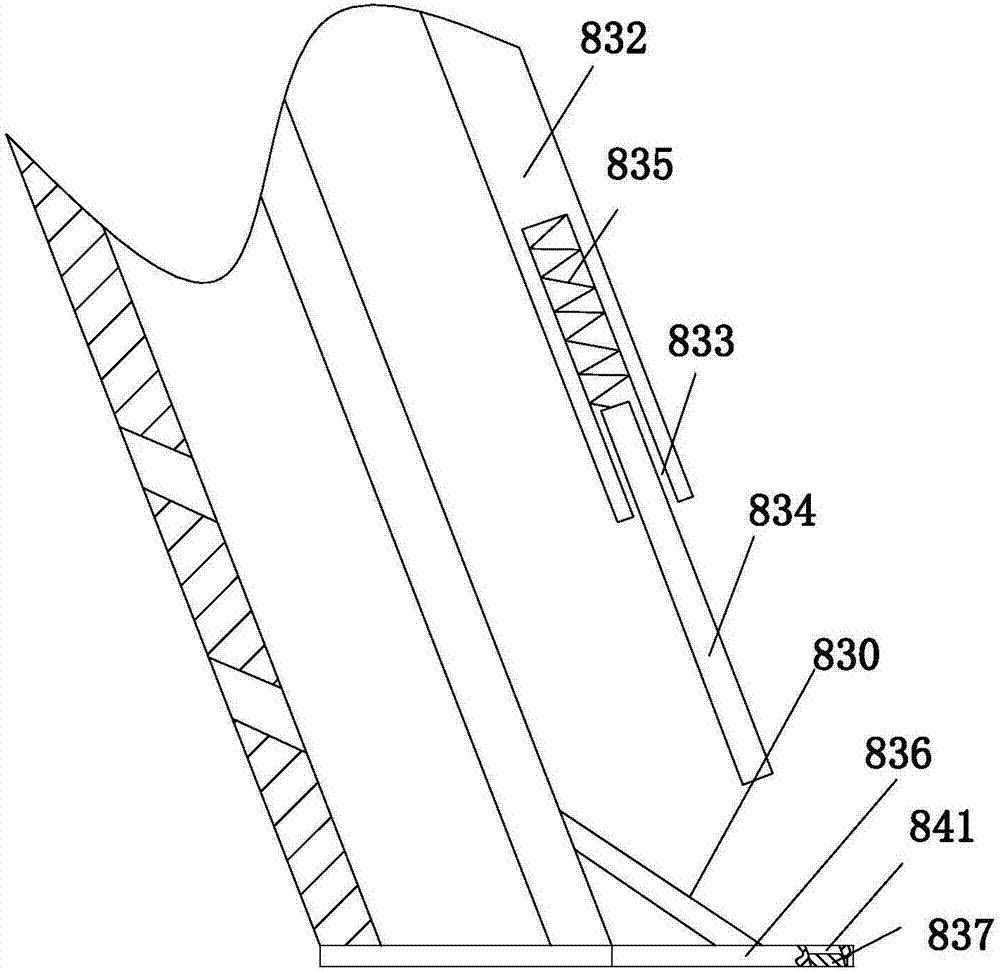

[0016] Example. A cotton collecting hopper of a disc plucking machine is constituted as Figure 1 to Figure 5 As shown, it includes an outer shell 818 and an inner shell 819 with a tapered cross-section, and the height of the inner shell 819 is lower than that of the outer shell 818. A partition 820 is provided between the outer shell 818 and the inner shell 819, and the inside of the partition 820 is a guide. The wind layer 821, the outer side of the partition 820 is a debris storage layer 822; the upper end of the debris storage layer 822 is provided with a fixed cover plate 823 and a movable iron plate 824, and the upper end of the wind guide layer 821 is provided with a top baffle 825, and the top baffle A movable groove 839 corresponding to the position of the movable iron plate 824 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com