A ring spinning frame employing a single-spindle atomization wetting device to reduce hair

A technology of ring spinning machine and wet-feeding device, applied in textiles and papermaking, etc., can solve problems such as failure to eliminate hairiness, reduce the number of harmful hairiness, be easy to use in a large area, and reduce the arc length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The "upstream" mentioned in the present invention refers to the upstream along the yarn moving direction, and the "downstream" refers to the downstream along the yarn moving direction.

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings.

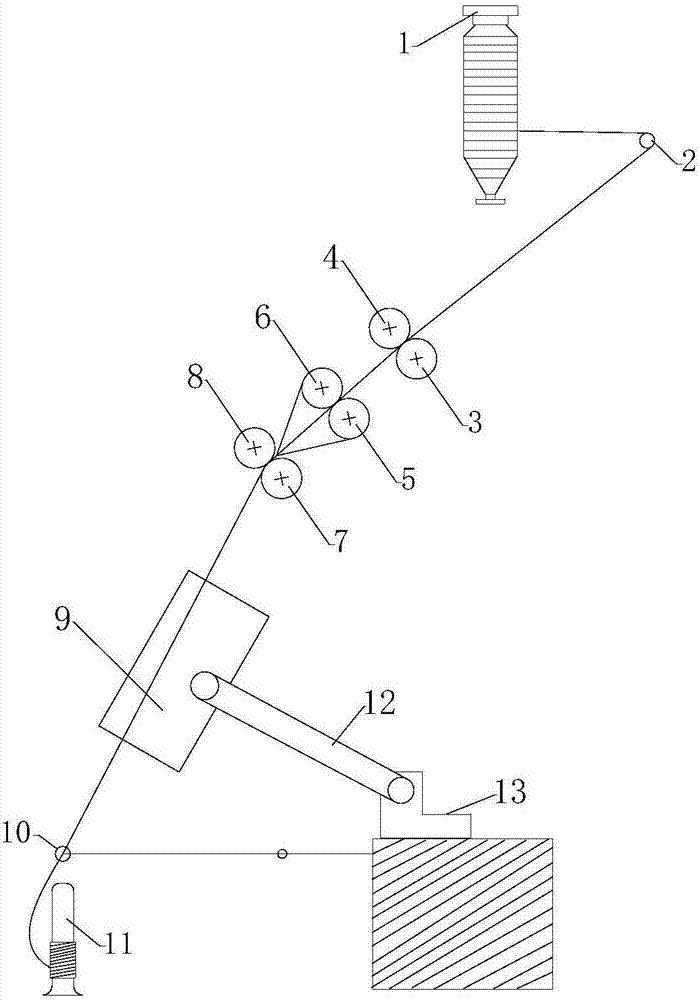

[0027] Please refer to figure 1 , in the spinning process, the roving 1 enters the rear nip of the rear roller 3 and the rear upper top roller 4 through the yarn guide rod 2, enters the middle nip of the middle roller 5 and the middle upper iron roller 6 through the rear drafting area, and then passes through The front drafting zone enters the front nip of the front roller 7 and the front top roller 8, and is twisted into yarn at the front nip, then contacts with the wet supply device 9, passes through the yarn guide hook 10, and is wound to the bobbin 11 on.

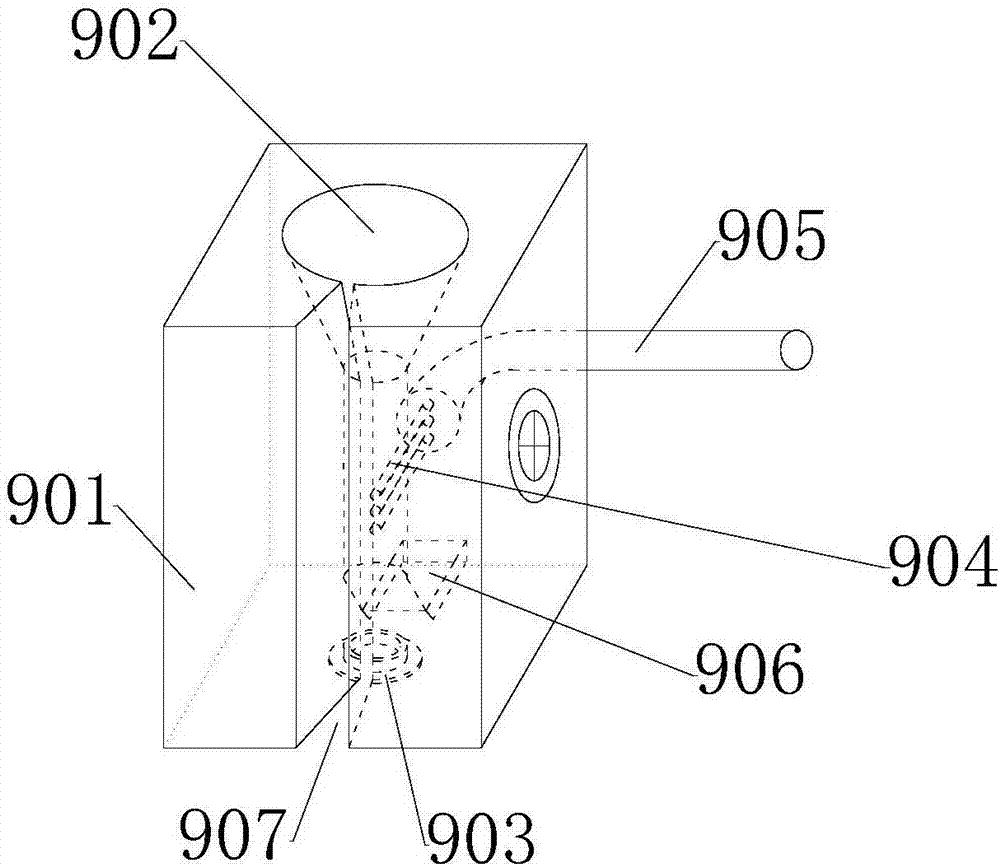

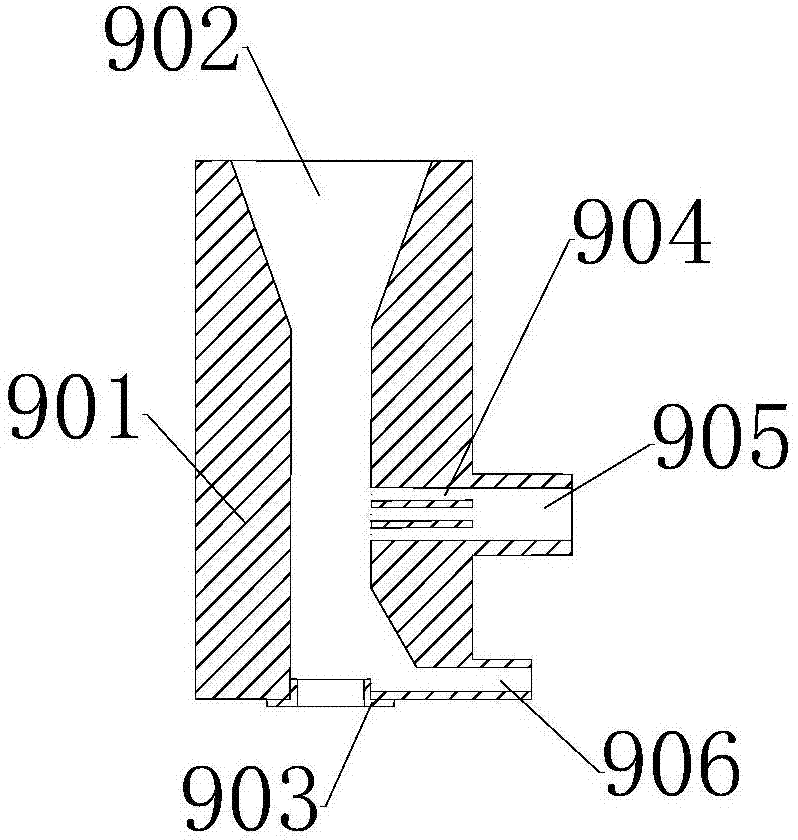

[0028] Such as Figure 2-4In one embodiment shown, the moisture supply device 9 of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com