Complete equipment for extracting corn stalk fibers through physical method

A technology of corn stalk fiber and complete equipment, which is applied in the field of complete equipment for extracting corn stalk fiber by physical method, which can solve the problems affecting the high-value utilization of straw and the inability to separate straw fiber from sponge body, etc., so as to facilitate maintenance and management and facilitate replacement Accessories, high separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

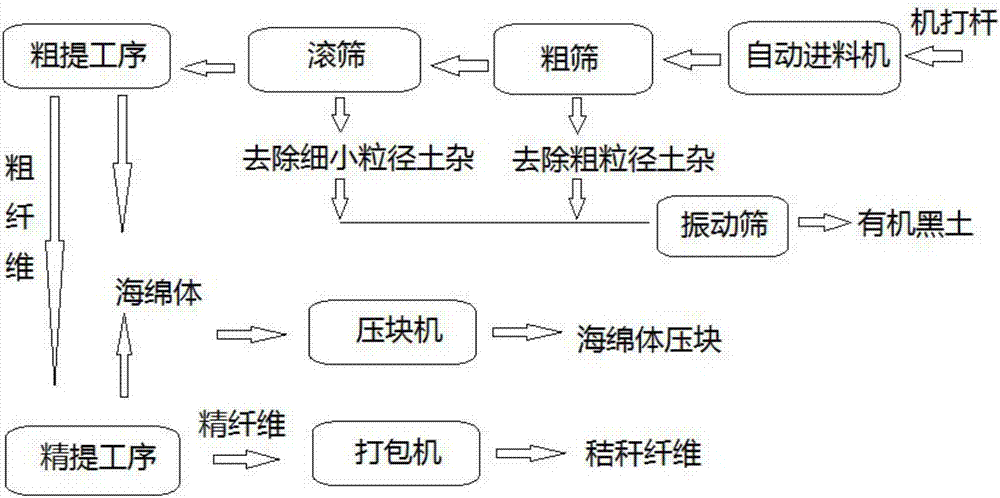

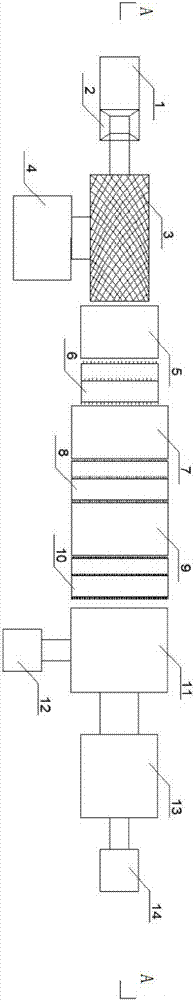

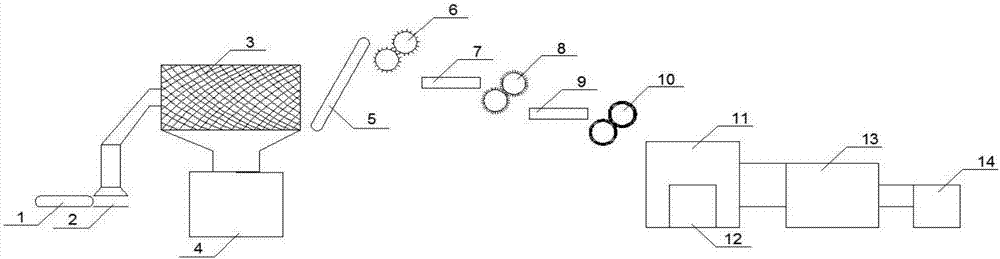

[0035] see Figure 2-7 , in an embodiment of the present invention, a complete set of equipment for extracting corn stalk fibers by physical methods mainly includes a soil debris stripping screen, a fiber rough extractor 8, a fiber fine extractor 10 and air separation equipment 2. The fiber rough extractor 8 and the fiber fine extractor 10 are all connected to the winnowing equipment 2 . The soil debris stripping screen includes a pair of roller compactors, a vibrating screen and a rolling screen 3. One end of the roller compactor is connected to the vibrating screen, the other end of the vibrating screen is connected to the winnowing equipment 2 through the quantitative conveyor 1, and the other end of the winnowing equipment 2 is connected to the rolling screen 3 through the transmission belt. The soil miscellaneous conveyor 4 connected by the L-shaped pipeline, the conveyor 5 is arranged under the other end of the roller screen 3, the crusher 6 is installed under the other...

Embodiment 2

[0038] The complete set of equipment of the patent of the present invention is mainly composed of a whole stalk crusher, a roller compactor, a vibrating screen, a fiber rough extractor 8, a fiber fine extractor 10 and air separation equipment 2 for the whole stalk of straw. After the whole stalk of straw enters the complete set of equipment, it is firstly cut and crushed by the whole stalk crusher, and the sticky soil on the surface of the straw is separated from the straw by a roller compactor. 3 The lower L-shaped pipeline and the soil miscellaneous conveyor 4 discharge the complete set of equipment. After the removal of soil debris, the straw enters the crusher 6 through the conveyor 5 for crushing, and after being screened by the screen A7, it enters 1-2 groups of fiber roughing machines 8, mainly using barbed needles to peel the fibers from the surface of the sponge body At the same time, the sponge body is crushed, and the coarse fiber and partially adhered sponge body e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com