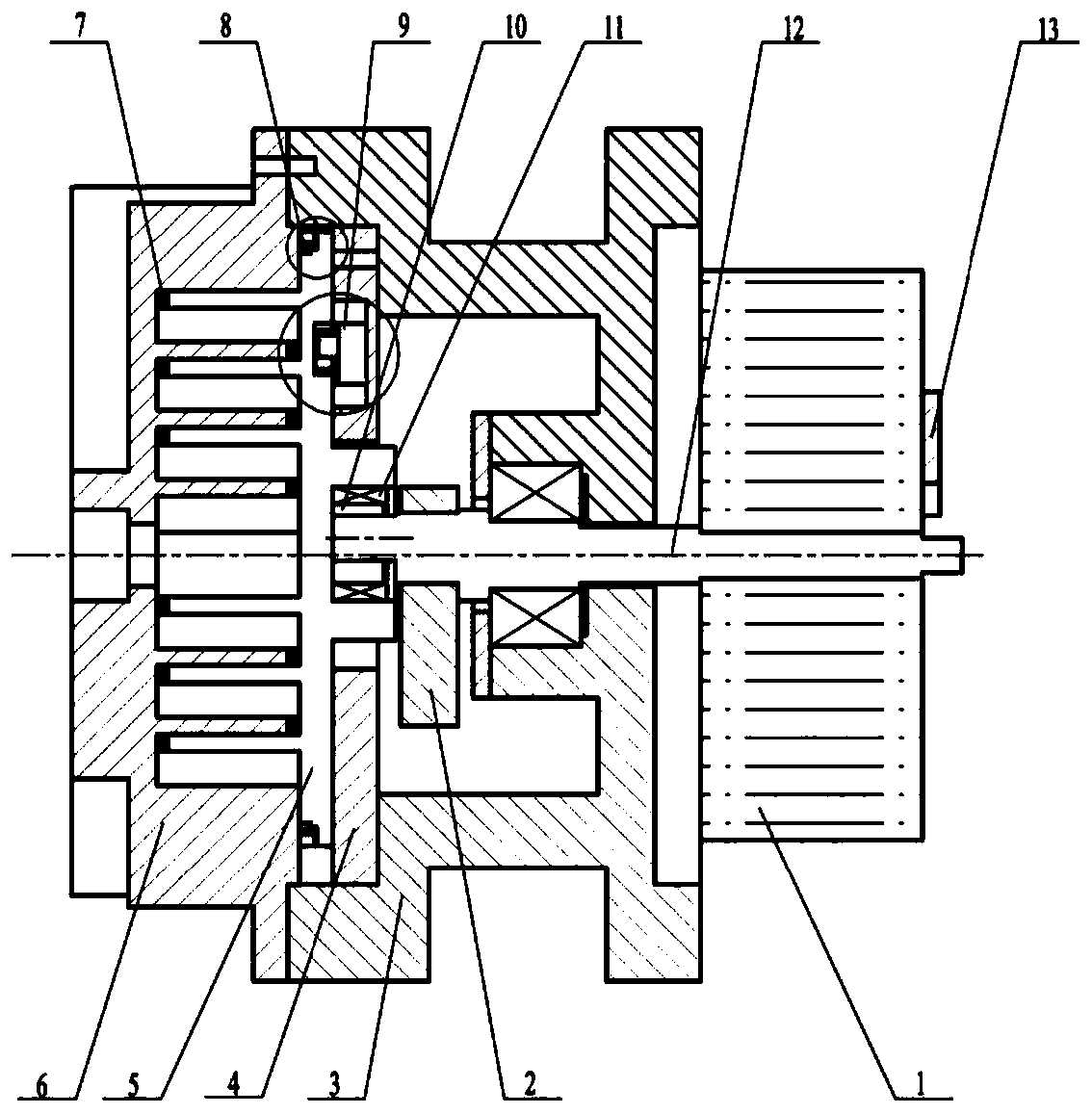

A kind of oil-free lubrication scroll vacuum pump

An oil-free lubrication, vacuum pump technology, used in rotary piston pumps, pumps, rotary piston/oscillating piston pump components, etc., can solve the problems of scroll overturning, vibration, unequal volume ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

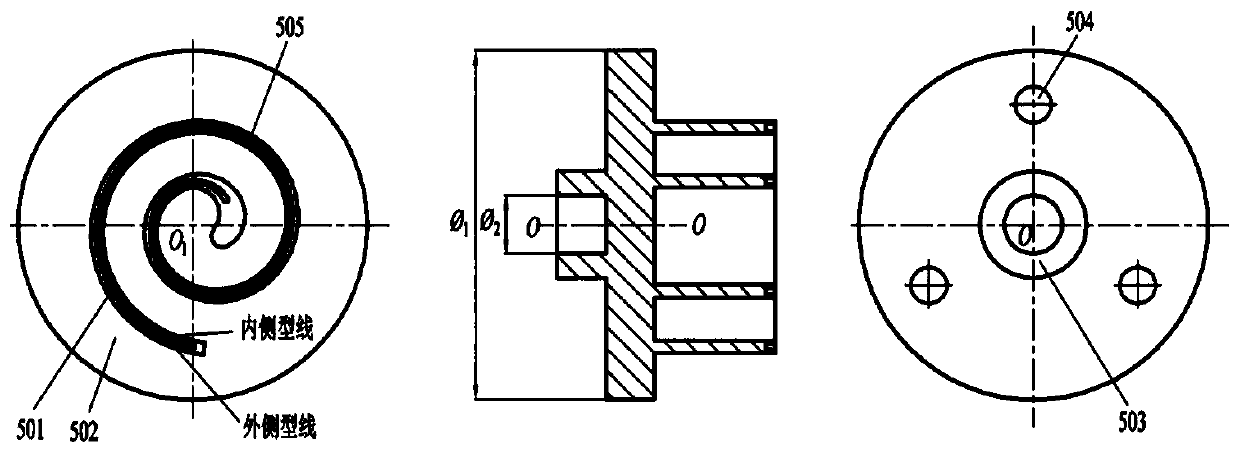

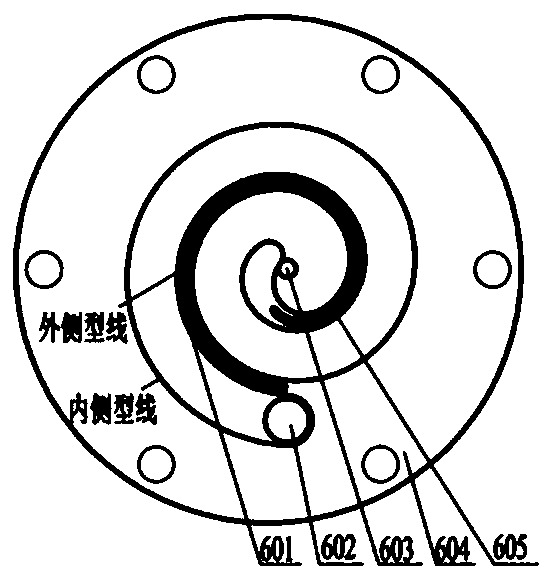

[0034] Such as Figure 7 Shown is a schematic diagram of the meshing state of the rotor designed for the tooth head of the movable scroll, which is the first embodiment to ensure that the volume ratio in the working chamber of the scroll vacuum pump is equal; Figure (a) is the inner profile of the movable scroll (501) The suction cavity S formed by the end and the outer molded line end of the fixed scroll (601) 21 ; Figure (b) is the exhaust chamber S formed by the inner profile of the movable scroll (501) and the outer profile of the fixed scroll (601) 22 ; Figure (d) is the suction cavity S formed by the outer profile end of the movable scroll (501) and the inner profile end of the fixed scroll (601) 11 ; Figure (e) is the exhaust chamber S formed by the outer profile of the movable scroll (501) and the inner profile of the fixed scroll (601) 12 ;when , the volume ratio in the working chamber of the scroll vacuum pump is equal; Figure (c) is an enlarged view of the meshi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com