Hydraulic machinery cavitation and gas-liquid two-phase flow monitoring method and device

A technology of gas-liquid two-phase flow and hydraulic machinery, which is applied in the direction of analyzing fluids, analyzing materials, and instruments using sound waves/ultrasonic waves/infrasonic waves. It can solve the problems that monitoring methods and devices are susceptible to interference and difficult to install, and achieve signal anti-interference Strong ability, convenient disassembly, and accurate judgment of flow state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A specific embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

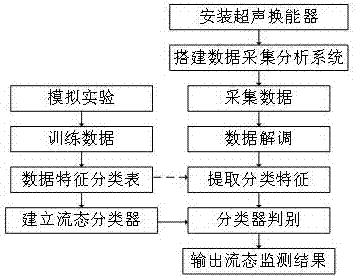

[0021] Such as figure 1 As shown, firstly, ultrasonic transducers are installed at the outlet of the hydraulic machinery to be tested, and a real-time data collection and data processing platform is built, and data demodulation is performed after data collection, and then classification features are extracted based on support vector machine pattern recognition and streamed according to the classifier. state discrimination, and finally output the gas fraction interval to which the flow state monitoring results belong.

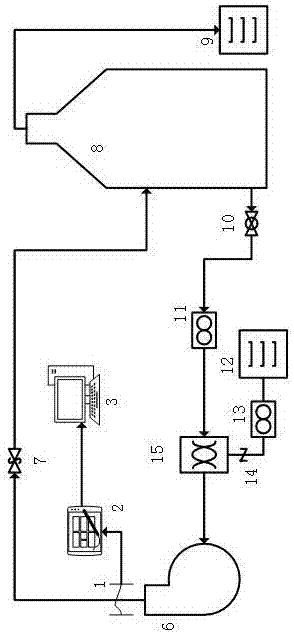

[0022] Such as figure 2 As shown, the simulation experiment is carried out before monitoring, including the data acquisition and analysis system formed by the ultrasonic transducer 1, the acquisition card 2, the computer 3, the data acquisition software 4, and the data analysis software 5, and through the centrifugal pump 6, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com