MEMS-sensing integrated ultrahigh frequency RFID label and read-out device

An RFID tag and ultra-high frequency technology, applied in the field of RFID, can solve the problems that the accidental MEMS sensor cannot upload information in real time, and cannot obtain information in time, so as to improve the performance and avoid the effect of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

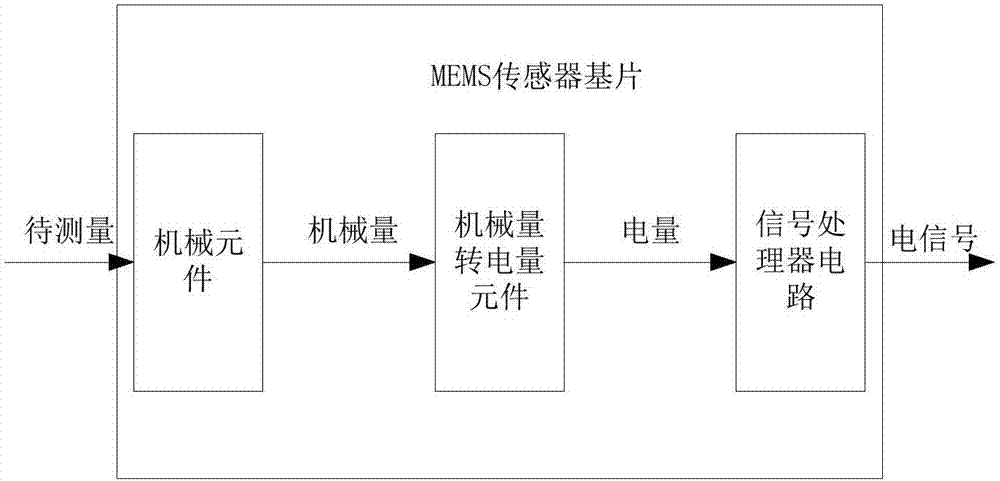

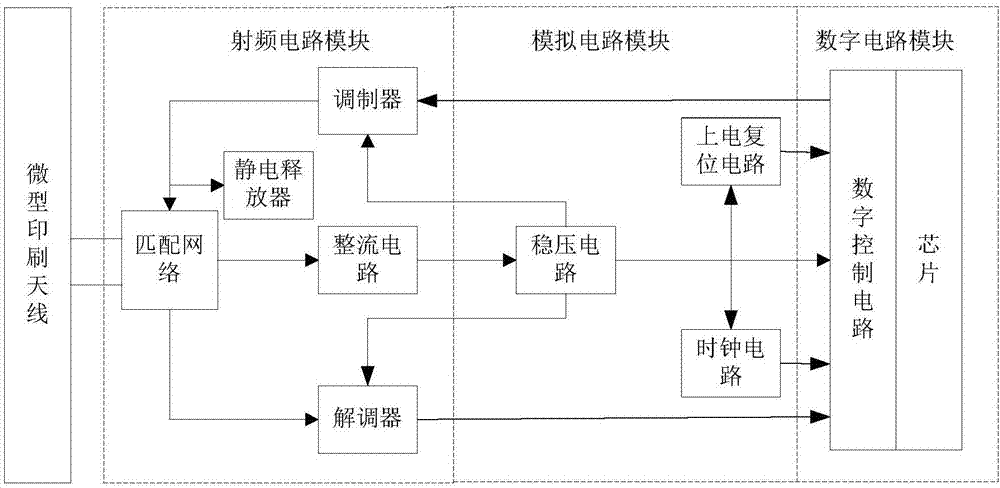

[0024] This embodiment provides a UHF RFID tag with integrated MEMS sensing, such as figure 1 and figure 2 As shown, it includes the integrated MEMS sensor substrate and UHF RFID substrate. The MEMS sensor substrate includes mechanical components, mechanical quantity-to-electricity components and signal processing circuits, mechanical components, mechanical quantity-to-electricity components and signal processing circuits. Connected in sequence, the UHF RFID substrate includes a miniature printed antenna, a radio frequency circuit module, an analog circuit module and a digital circuit module, and the miniature printed antenna, a radio frequency circuit module, an analog circuit module and a digital circuit module are connected in sequence. The mechanical quantity-to-electricity component is specifically an electromechanical component or an electromechanical photoelectric component. After receiving the physical object to be measured, the mechanical component quantifies the ph...

Embodiment 2

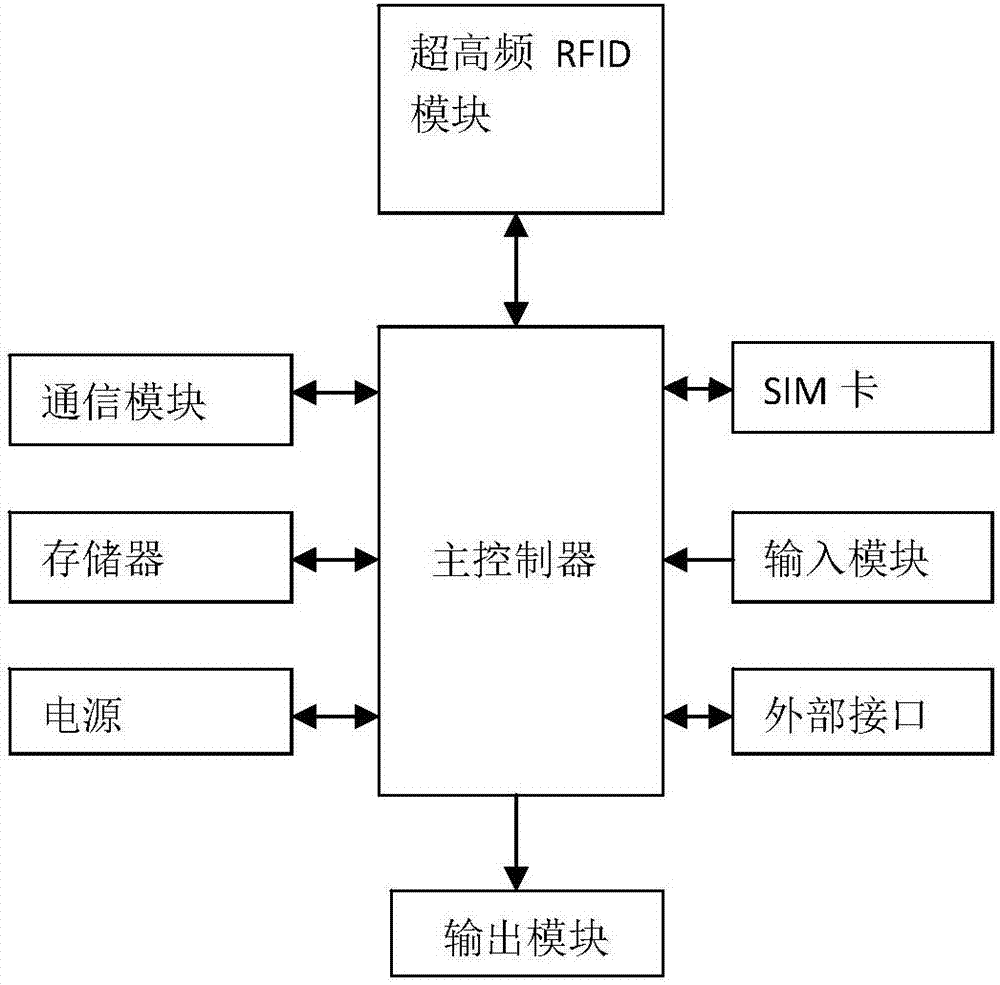

[0026] This embodiment is the reading device of the label in embodiment 1, such as image 3 As shown, it includes a main controller, a communication module, a card module, a power supply, a memory, a Bluetooth UHF RFID module for an ad hoc network, an external interface, an input module and an output module, the communication module, a card module, a power supply, The memory, the Bluetooth UHF RFID module, the external interface, the input module and the output module are respectively connected to the main controller. The main controller is the data processing center and the control center, the communication module is used for data communication, the card module is a chip card and surrounding circuits, the chip card can be a SIM card, the power supply provides energy for each module, and the memory is used to store data. Frequency RFID working frequency is 840-925M Hz. The external interface is used to connect various devices, such as headphones, the input module is used to i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com