Method and device for recovering farmland mulch residues

A residual film recovery and farmland technology, applied in the field of agricultural machinery, can solve the problems of pollution, machine damage, high labor intensity, etc., and achieve the effect of clear removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

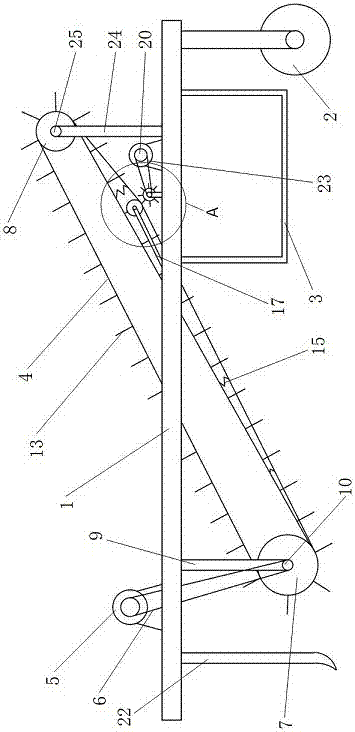

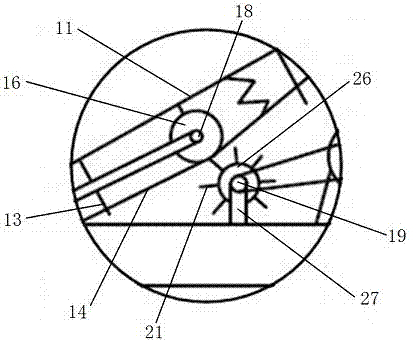

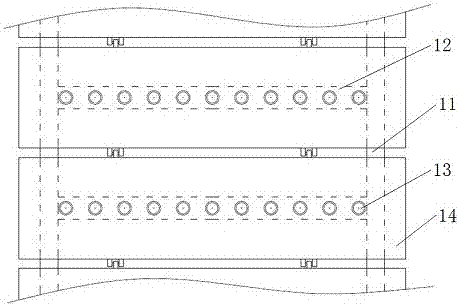

[0027] Please refer to figure 1 , figure 2 and image 3 , This embodiment provides a farmland residual film recovery device. Such as figure 1 , figure 2 and image 3 As shown, the farmland residual film recovery device includes a support frame 1, a ground wheel 2, a first motor 5, a driving wheel 7, a driven wheel 8, a recovery box 3, and a film picking chain belt 4; the driving wheel 7 passes through the driving wheel support rod 9 And the drive wheel shaft 10 is fixed below the support frame 1, the drive wheel shaft 10 is statically connected with the drive wheel 7, the first motor 5 is arranged on the support frame 1, and links to each other with the drive wheel shaft 10 by the first motor drive belt 6 to Drive the driving wheel 7 to rotate, the driven wheel 8 is fixed on the top of the support frame 1 by the driven wheel support rod 24 and the driven wheel rotating shaft 25, the driven wheel rotating shaft 25 is dynamically connected with the driven wheel 8, the gro...

Embodiment 2

[0035] This embodiment provides a method for recycling farmland residual film, which is carried out by using the device for recovering farmland residual film provided in Example 1. Firstly, the plastic film on the advance route of the device is separated from the plastic film on both sides by the film cutter 22, and then the residual film on the farmland is picked up by the film picking chain belt 4 and the stripping wheel 16, and the residual film is recovered by the film cleaning wheel 26. In recycling box 3.

[0036] The method for recovering residual film in farmland provided by the invention has few procedures, simple steps and obvious cleaning effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com