Production process of wood-plastic plate capable of being directly nailed

A production process and wood-plastic board technology, applied in the field of wood-plastic board production technology, can solve the problems of easy water accumulation and cracking of solid wood-plastic boards, and achieve the effects of easy penetration and reduced product density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0024] A wood-plastic board production process that can be nailed directly, mainly including mixing, granulation, and extrusion production processes;

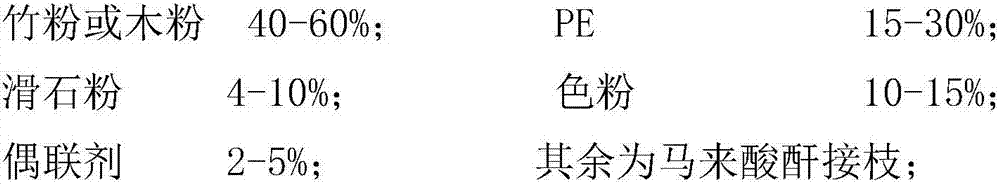

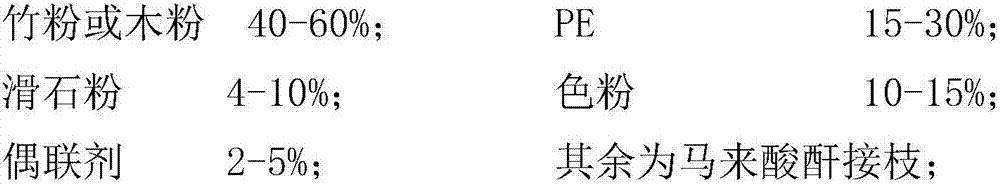

[0025] In the granulation process, the required raw material components and component quantities are:

[0026]

[0027] The sum of the amounts of the above components satisfies 100%;

[0028] During the mixing process, the materials are mixed according to the formula, and the materials are stirred at a high speed by the mixer to generate heat by friction. After reaching the set process temperature of 110 ° C ~ 125 ° C, they are discharged into the cold mix, and the materials are discharged after the set process temperature of 40 ° C;

[0029] In the granulation process, the above-mentioned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com