Automatic support feeding system for LED die bonder and running method of automatic support feeding system

A technology of LED die bonding machine and automatic feeding, which is applied to conveyor objects, transportation and packaging, semiconductor/solid-state device manufacturing, etc. The effect of improving the degree of automation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

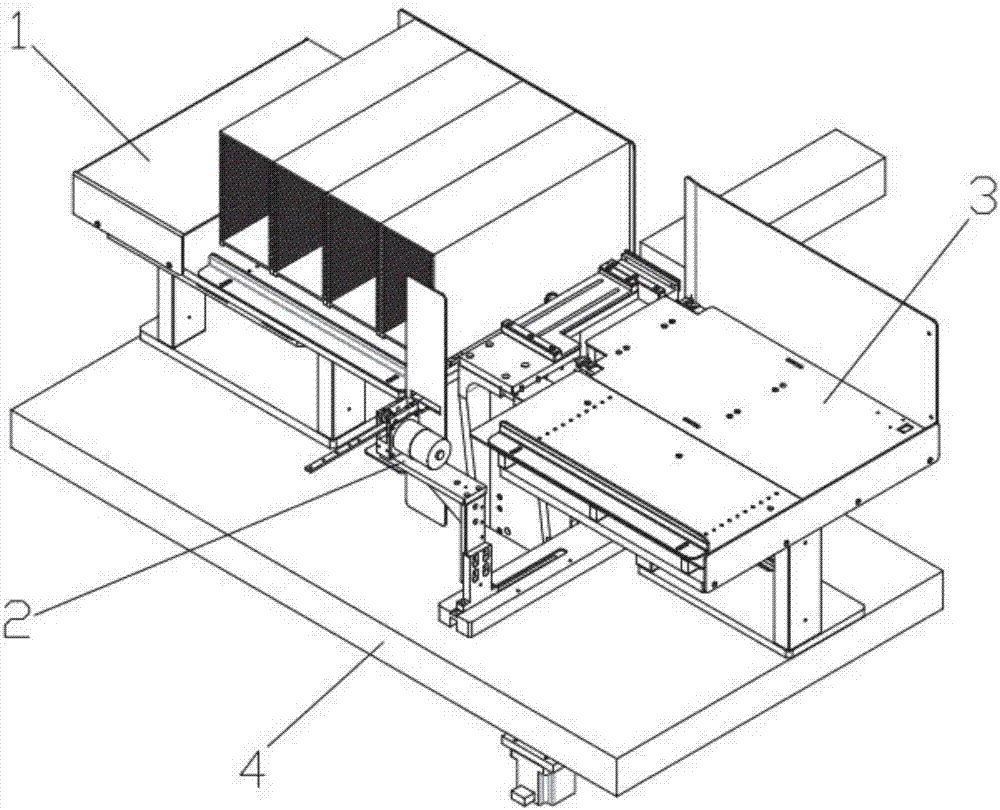

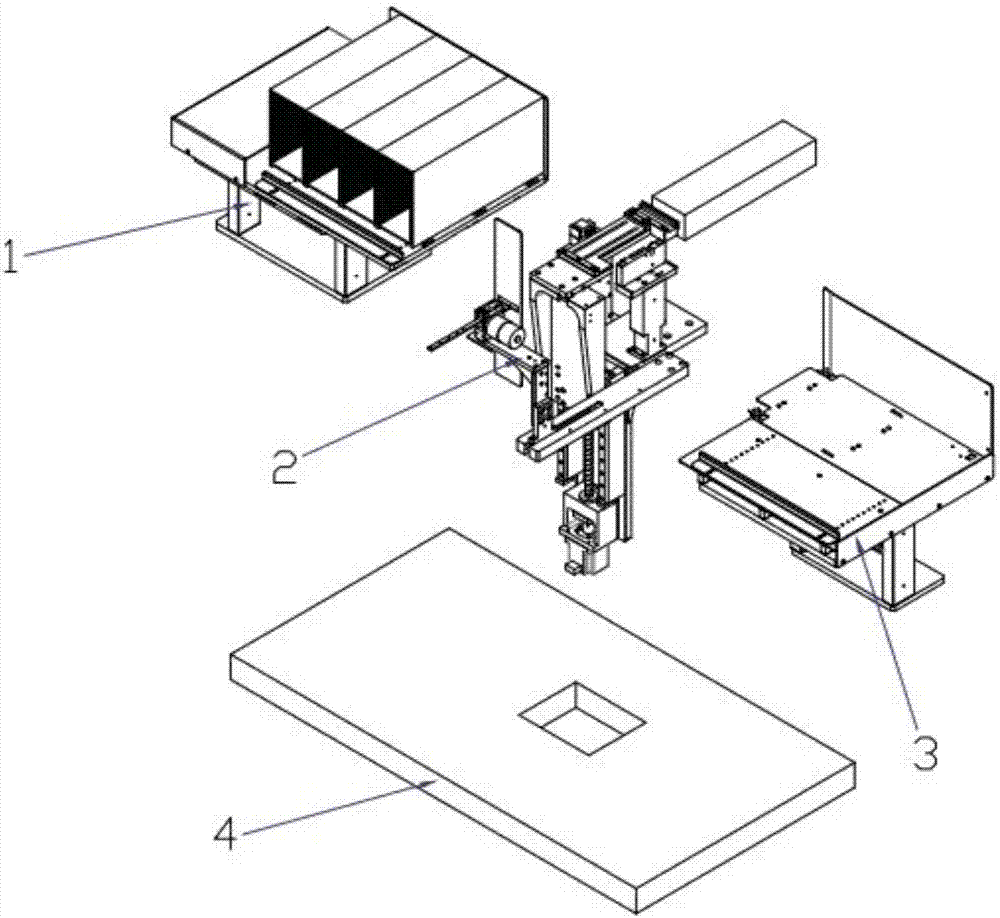

[0057] Please refer to the attached Figure 1-2 , a bracket automatic feeding system for LED crystal bonding machine of the present invention, the automatic feeding system includes:

[0058] A platform 4 is provided with a through hole;

[0059] A feeding box device 1 which is arranged on the feeding position of the platform 4 and is used to carry the magazines filled with the brackets to be processed and separate the magazines of the brackets to be processed one by one

[0060] A support receiving device 2 arranged on the processing position of the platform 4 and used for pushing out and recovering the support from the material box;

[0061] Set on the material receiving station of the platform 4, the material receiving box device 3 for carrying the processed material boxes.

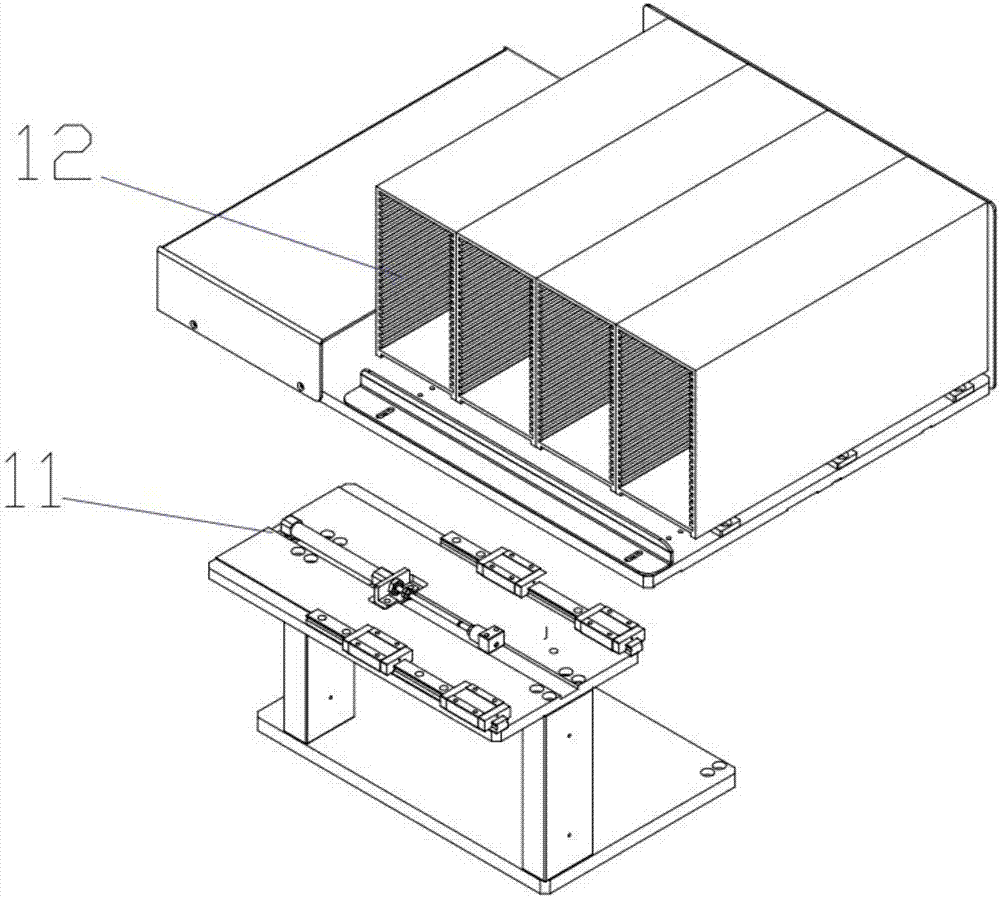

[0062] Such as Figure 3-5 As shown, the feed box device 1 includes a feed frame 11 and a push box assembly 12;

[0063] The feed frame 11 includes a mounting frame 1101, a first guide rail 1102, an...

Embodiment 2

[0085] Embodiment 2: An LED crystal bonder, including the above-mentioned bracket automatic feeding system for the LED crystal bonder.

Embodiment 3

[0086] Embodiment 3: An LED crystal bonder, including the operation method of the bracket automatic feeding system for the LED crystal bonder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com