Wound dressing for wound treatment in damp or wet environment

A wound dressing, wet technology, applied in dressings, adhesive dressings, non-adhesive dressings, etc., can solve problems such as wound healing interference, achieve improved grip, improved bendability and drapability, and improved sensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

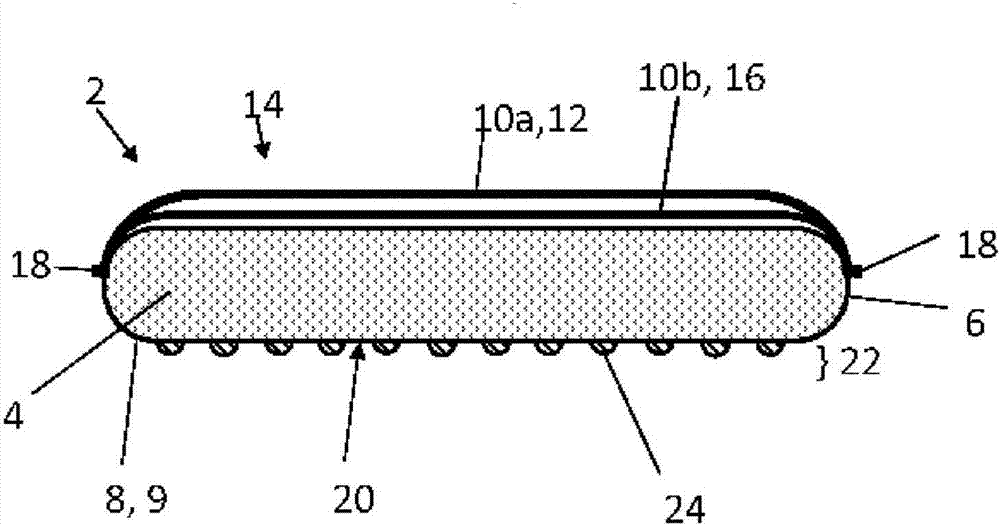

[0027] figure 1 The wound dressing 2 is shown in section. It comprises a nonwoven-based suction / irrigation body 4 . The fiber base involves a preferred mix of cellulose fibers (cellulose) and polypropylene fibers or polypropylene / polyethylene fibers placed in the air. These fiber mixtures are superabsorbent polymer material (SAP) mixed as uniformly as possible in the form of granules or in the form of fibers, wherein the SAP fraction accounts for preferably 40-50% by weight of the total mass of the suction / irrigation body 4 . The average particle size of the SAP particles is, for example, between 150 and 850 μm (eg polyacrylate Favor pac 300 from Evonik Stockhausen GmbH).

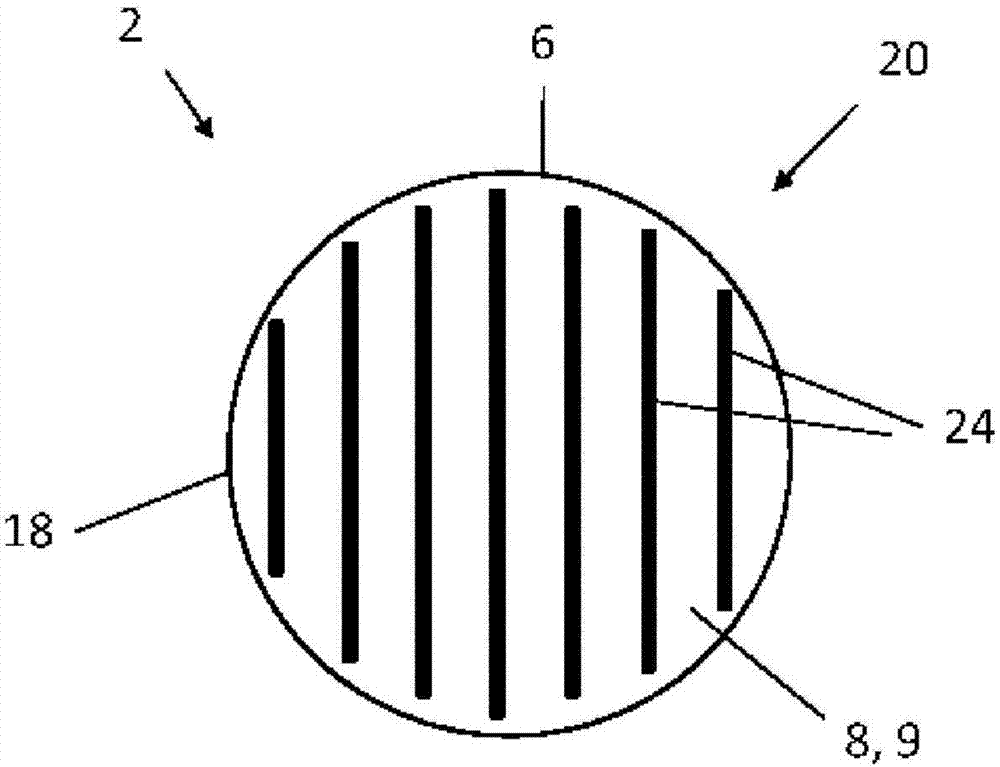

[0028] The suction / irrigating body 4 is surrounded by a wrapping 6 forming the outside of the wound dressing, which is composed of an envelope 8 facing the wound and two envelopes 10a, b facing away from the wound. The wrapping layer 8 facing the wound is preferably a layer 9 made of a textile surface ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com