Method and apparatus for joining workpieces at a lap joint

A technology for connecting devices and joints, used in welding/welding/cutting items, manufacturing tools, welding equipment, etc., to solve problems such as loss of material fluidity and introduction of multi-power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

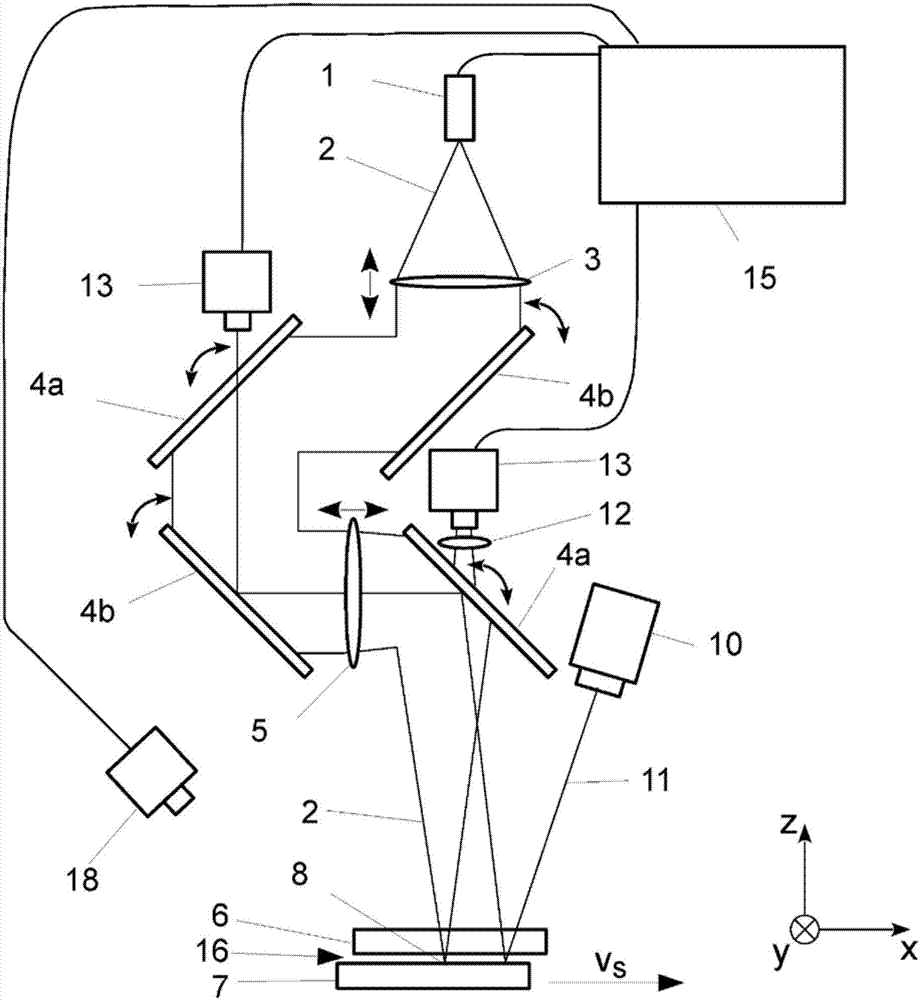

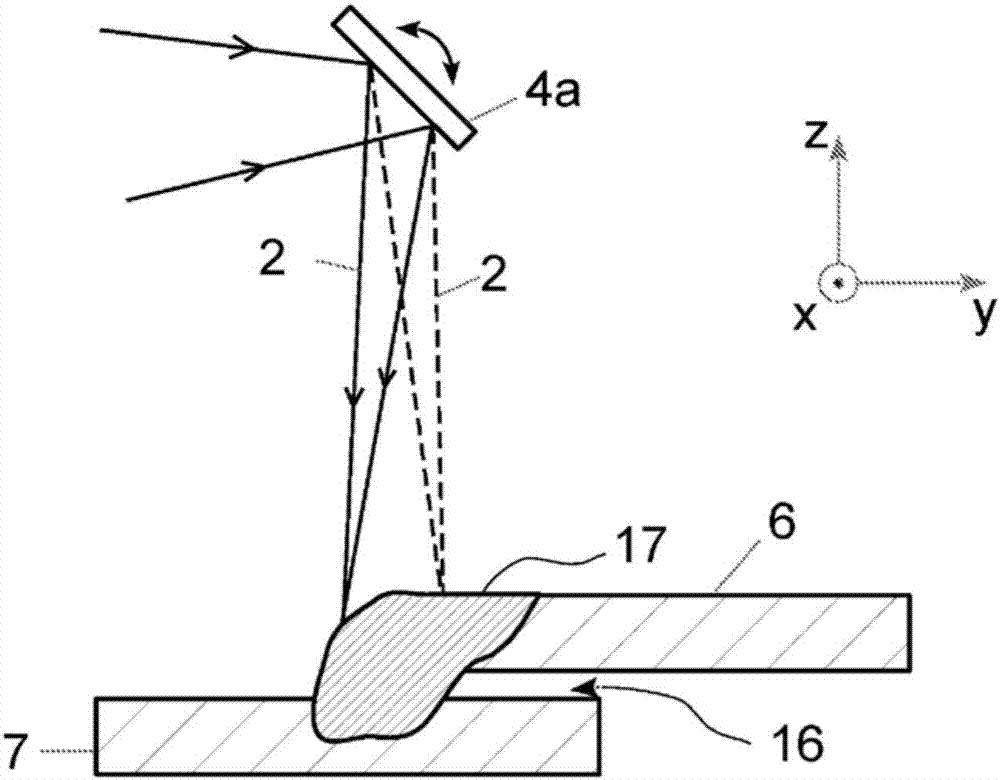

[0054] according to figure 1 The connecting device is a laser beam welding device with remote-controlled laser processing optics; the processing beam is thus a laser. The laser beam production unit 1 generates a laser beam 2 which is aimed by an aiming unit 3 movable along the beam axis onto a deflection unit 4 a oscillating about its respective transverse axis and a deflection unit 4 b oscillating about its longitudinal axis. The focusing unit 5 finally produces a laser burn spot 8 on the surfaces of the workpieces 6 (upper plate) and 7 (lower plate), which burns at a feed speed V s Move along the connection junction.

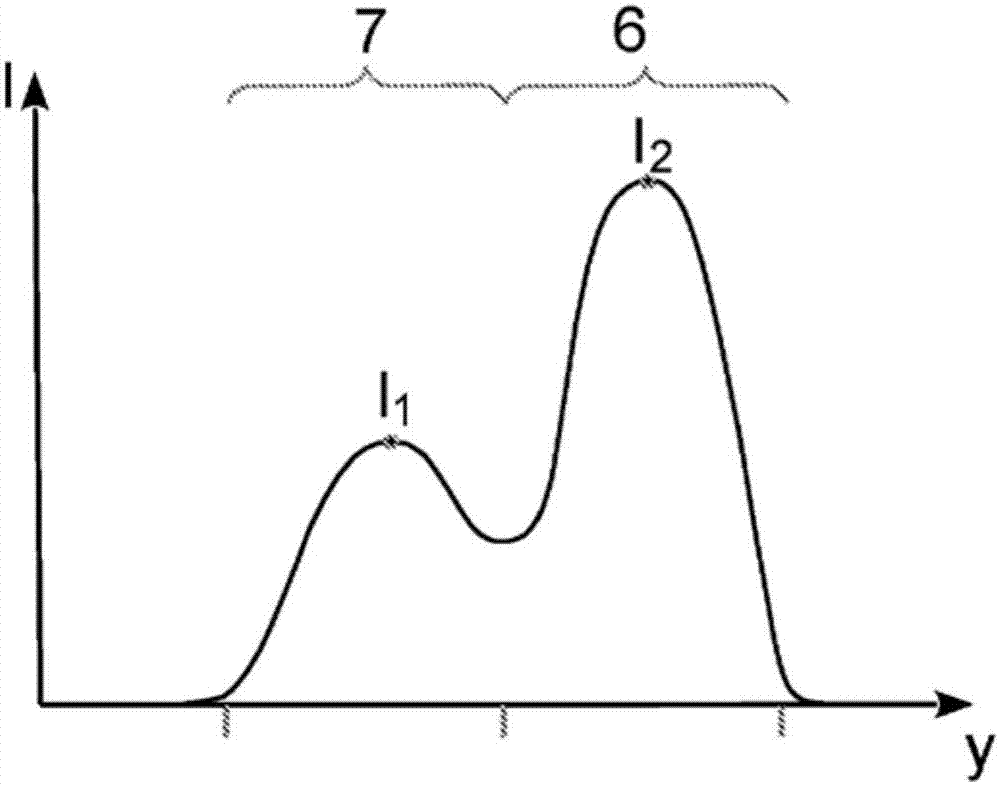

[0055] The projection device 10 projects a beam of light perpendicular to the joining point onto the workpiece surface with the measuring beam 11 . The sensor 13 detects the light, wherein the sensor focusing unit 12 can be connected in series at the front end of the sensor 13 . The evaluation and regulation unit 15 connected to the sensor thus calculates t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com