Worm gear for an electromechanical power steering system

A technology of power steering and worm gear, which is applied in the direction of mechanical equipment, components with teeth, belts/chains/gears, etc. It can solve the problems of high tolerance requirements, service life, etc., and achieve the effect of good strength characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

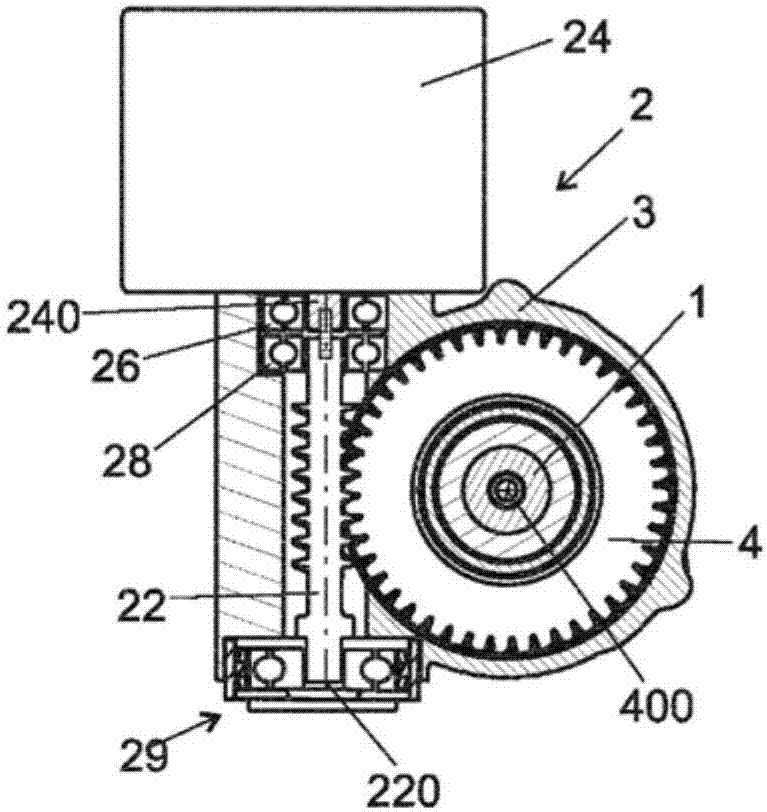

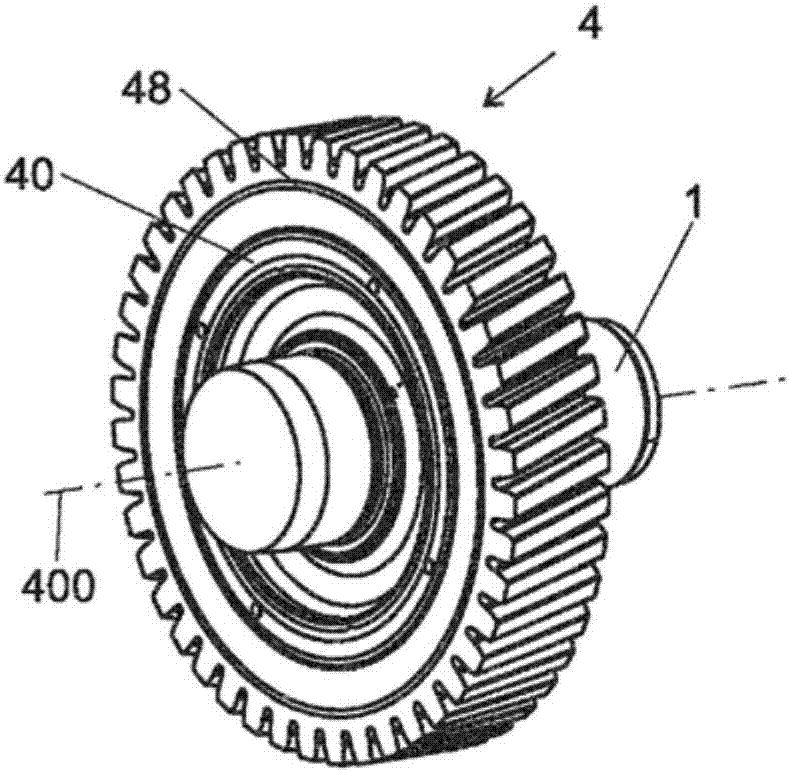

[0064] Next, preferred embodiments will be described with reference to the drawings. Identical, similar and identically acting elements are marked with the same reference signs. In order to avoid redundant information, repeated descriptions of these elements are partially omitted in the ensuing description.

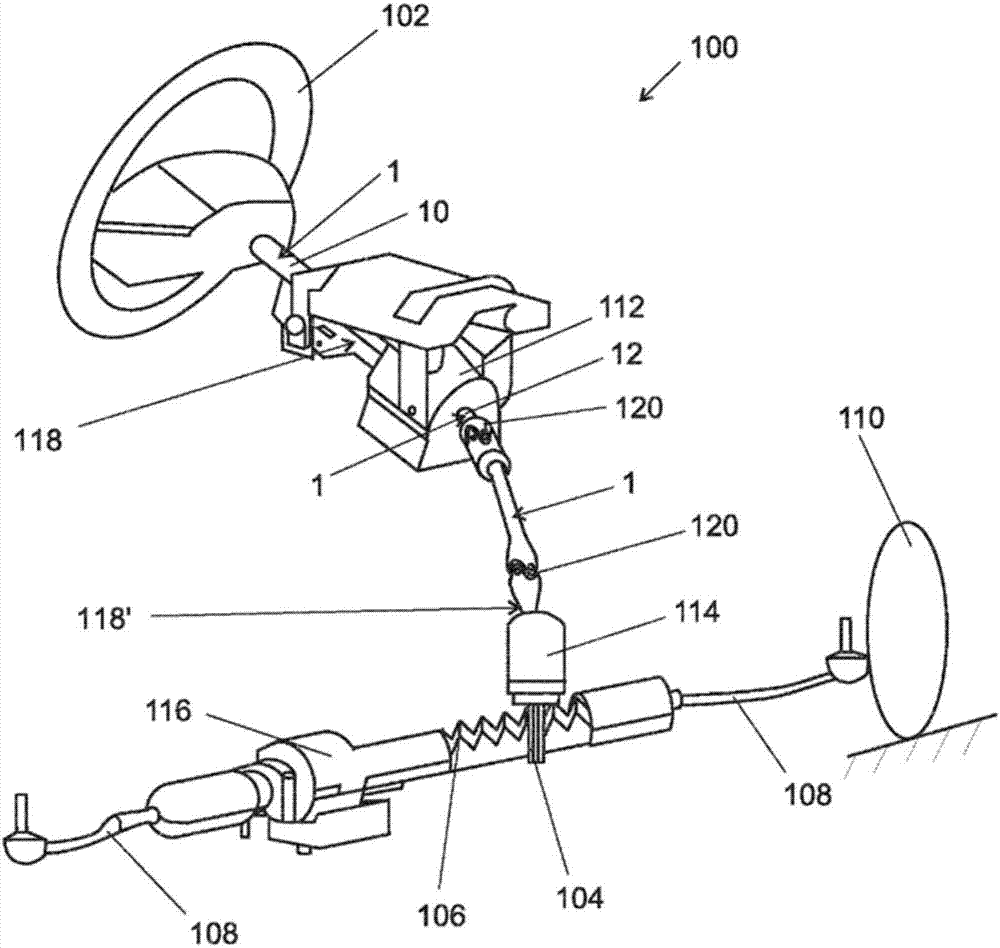

[0065] figure 1 An overview of a steering system 100 of a motor vehicle is shown, in which the driver can apply a corresponding torque to the steering shaft 1 as a rotation command via a steering wheel 102 . The torque is then transmitted via the steering shaft 1 to the steering pinion 104 , which meshes with the toothed rack 106 , which then transmits the aforementioned steering angle on its side via the corresponding tie rod 108 to the steerable wheels 110 of the vehicle.

[0066] An electric and / or hydraulic booster strut can be provided in the form of booster strut 112 coupled to steering shaft 1 , booster strut 114 coupled to steering pinion 104 and / or booster stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com