Clearing mechanism used for scale substances of inner circumferential wall of pipefitting

A technology of inner circumference and pipe fittings, which is applied in the field of pipe fitting maintenance equipment, can solve the problems of decreased fluid flow rate in pipes, incomplete cleaning of dirt, and reduced pipeline transportation efficiency, so as to improve transportation efficiency, avoid impact, and reduce the probability of stress fracture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

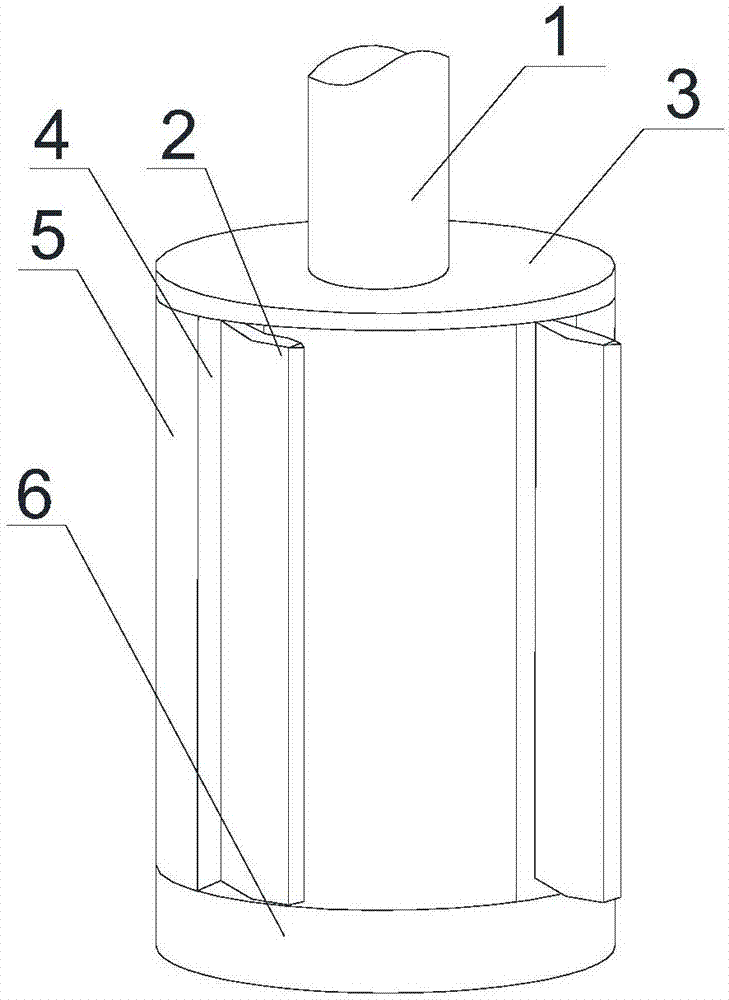

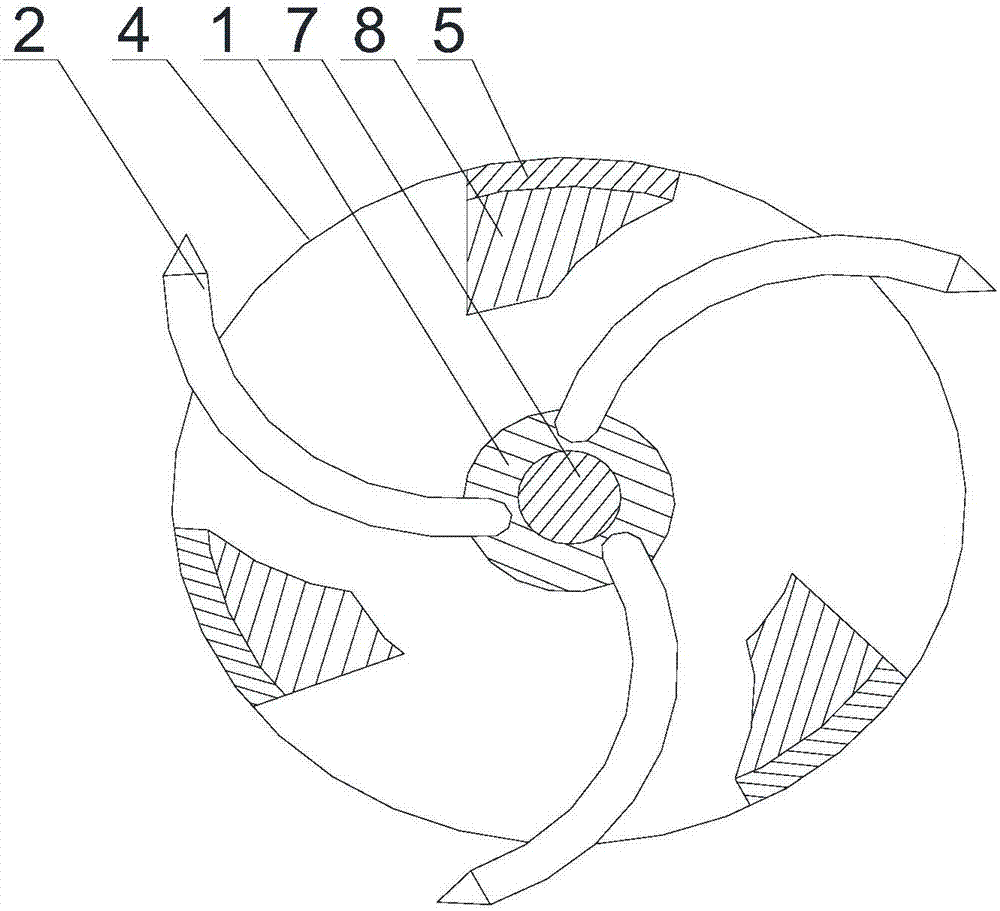

[0021] like figure 1 and figure 2 As shown, this embodiment includes a cylinder body 5, a rotating shaft 1, an end cap 3 and a base 6. The end cap 3 will be sealed with the upper end of the cylinder body 5, and the base 6 is screwed to the lower end of the cylinder body 5. The middle part of the upper surface of the base 6 is fixed with a screw 7, and the rotating shaft 1 moves downwards after penetrating through the middle of the end cover 3, and along the axial direction of the rotating shaft 1, a screw hole matching the screw 7 is opened on the lower end surface thereof. A plurality of arc-shaped cutting blades 2 are arranged on the rotating shaft 1, and the plurality of cutting blades 2 are fixedly connected with the rotating shaft 1 and evenly distributed on the outer peripheral wall of the rotating shaft 1. A plurality of adjustment holes 4 are opened on the peripheral wall, and the cutting piece 2 extends outward after penetrating the adjustment holes 4. A limiting bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com