One-time forming mold for graphite crucible

A technology for forming molds and graphite crucibles, which is applied in the direction of molds, ceramic molding machines, mold auxiliary parts, etc., can solve the problems of high cost of graphite crucibles, limited length of crucible body, cumbersome processing process, etc., and achieve low scrap rate and low production cost , labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

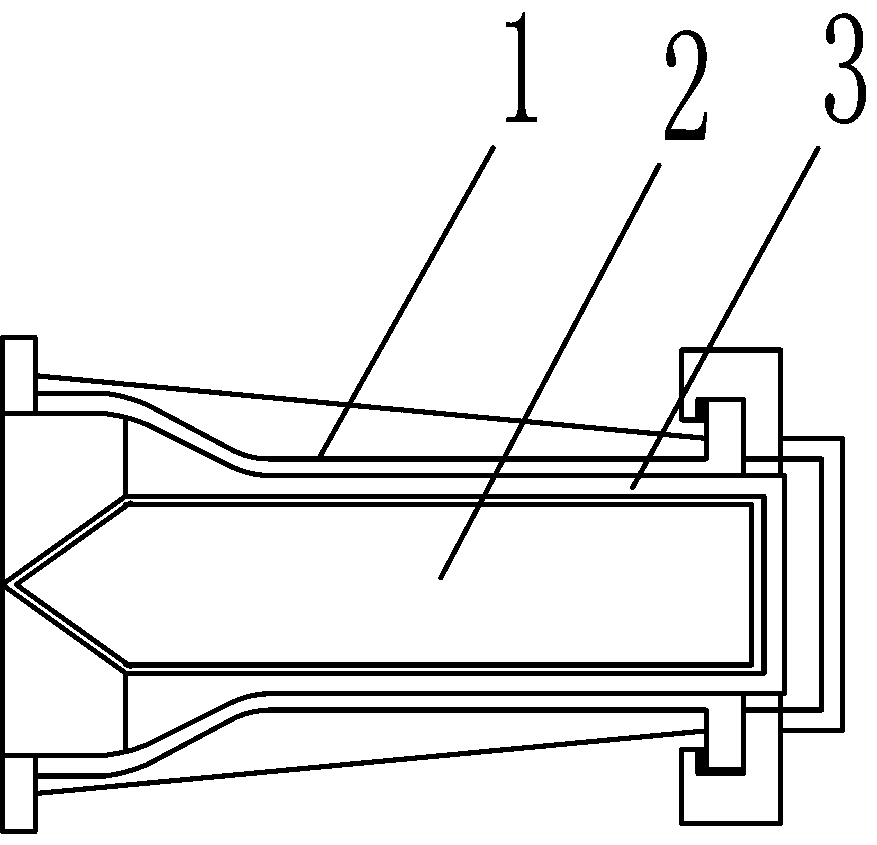

[0021] See figure 1 and figure 2 , a graphite crucible forming mold of the present invention, comprising a mold main body, a movable front door and an opening and closing cylinder, the movable front door is covered at the right end of the mold main body, and the piston rod of the opening and closing cylinder is connected to the movable front door; the mold main body includes an outer tube body 1 And the inner core body 2, the outer tube body 1 is a hollow structure with openings at both ends, the inner core body 2 is built in the outer tube body 1, and a flow channel 3 is formed between the outer tube body 1, the inner core body 2 and the movable front door.

[0022] The outer tube body includes a large-diameter section, an inclined section and a small-diameter section, and the inclined section is arranged between the large-diameter section and the small-diameter section.

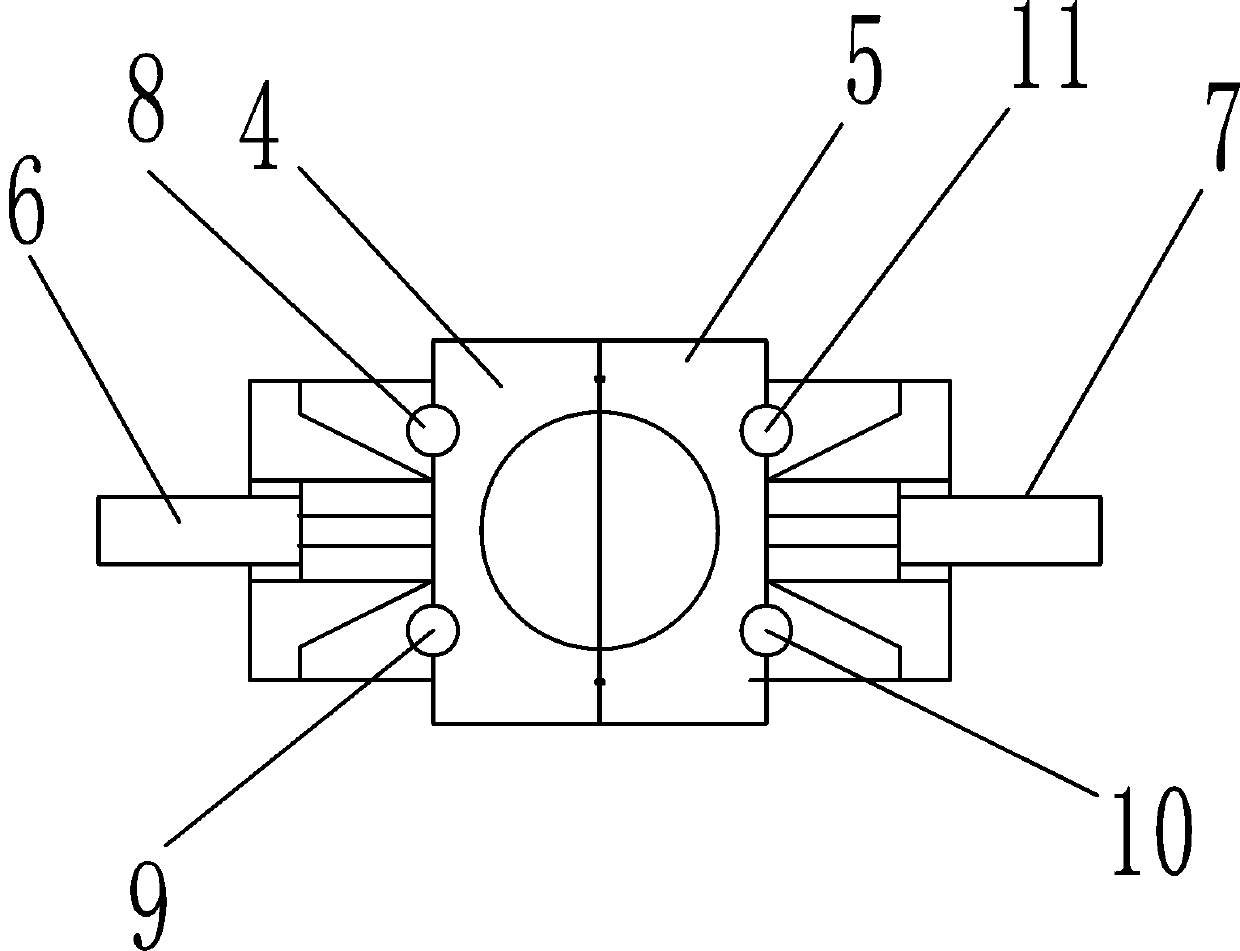

[0023] Described movable front door comprises left movable front door 4 and right movable front door 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com