Quasi-constant-pressure pressurizing system of vibration forming machine

A technology of vibration molding machine and pressurization system, which is applied to material molding presses, presses, manufacturing tools, etc., can solve problems such as low production efficiency, poor bending resistance, resistance and other indicators, and the body density of key technical indicators of products. , to reduce cracks and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that the following description is only for explaining the present invention and not limiting its content.

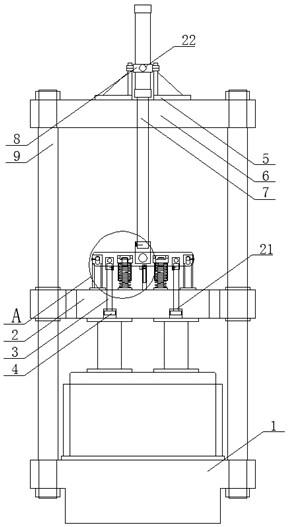

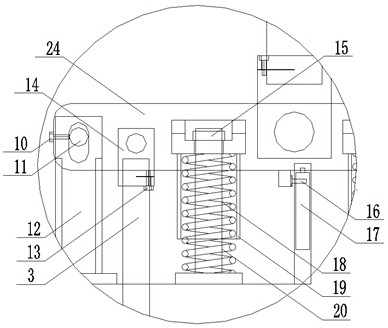

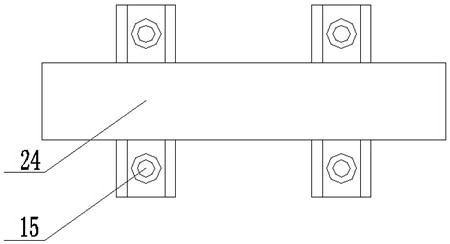

[0022] refer to Figure 1-7 , a quasi-constant pressure pressurization system for a vibration forming machine, comprising a bottom beam 1, a beam 24, a double-speed hydraulic system and four guide posts 9, the four guide posts 9 are arranged on the bottom beam 1, and the four guide posts 9 There is a weight 2 slidingly connected together, and the weight 2 slides up and down on the guide post 9 to apply pressure to the mold box. The lower end of the beam 24 is connected to a damper 16, and the damper 16 detects the moving position of the weight 2. 2 Move the position, change the force applied by the hydraulic cylinder 7, the displacement sensor 17 is installed on the weight 2, the damper 16 and the displacement sensor 17 are set co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com