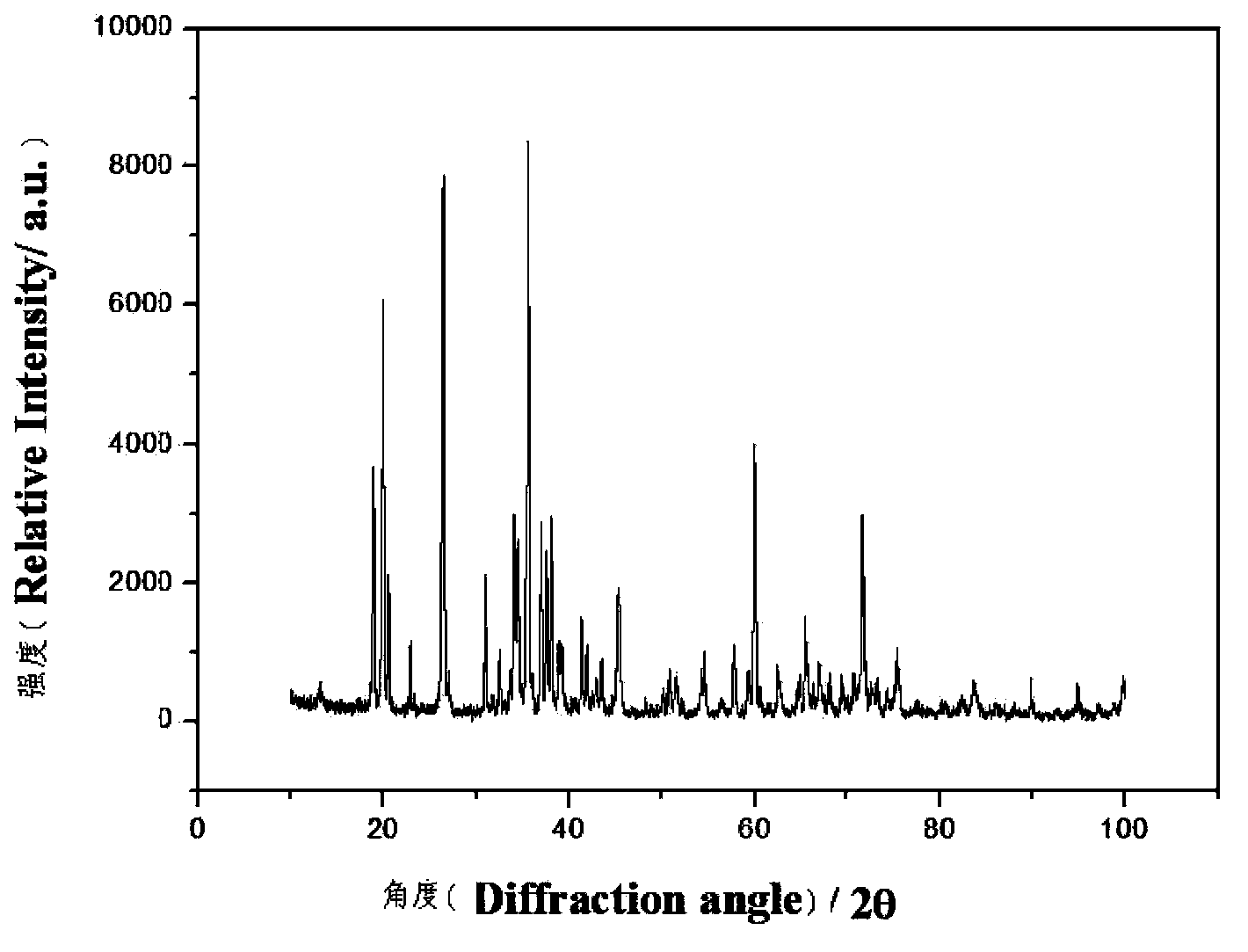

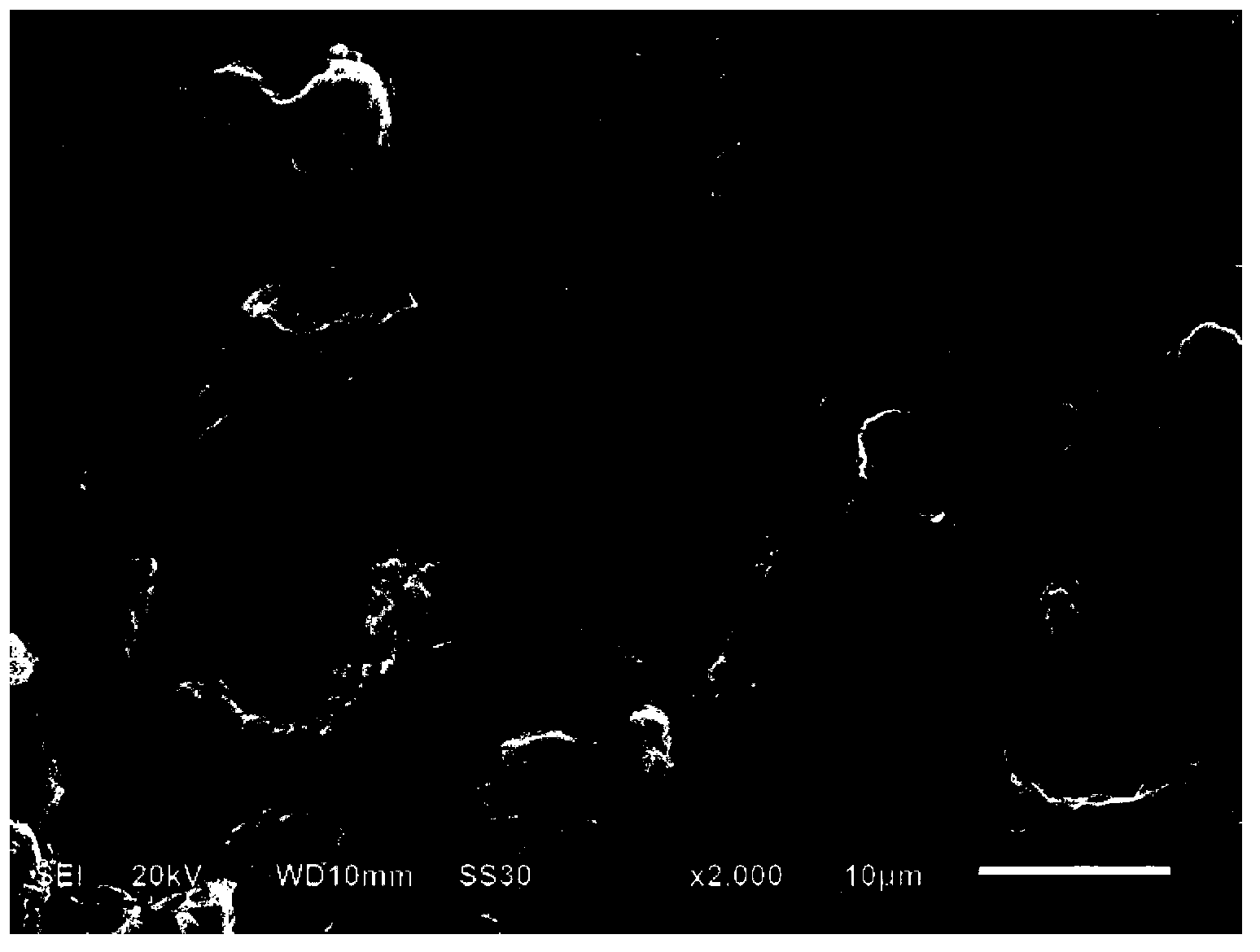

Si-B-C-N material applicable to high-temperature material and preparation method thereof

A high-temperature material, si-b-c-n technology, applied in the field of inorganic non-metallic materials, can solve problems such as performance that have not been reported, and achieve the effects of increased bulk density, increased high-temperature strength, and reduced porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

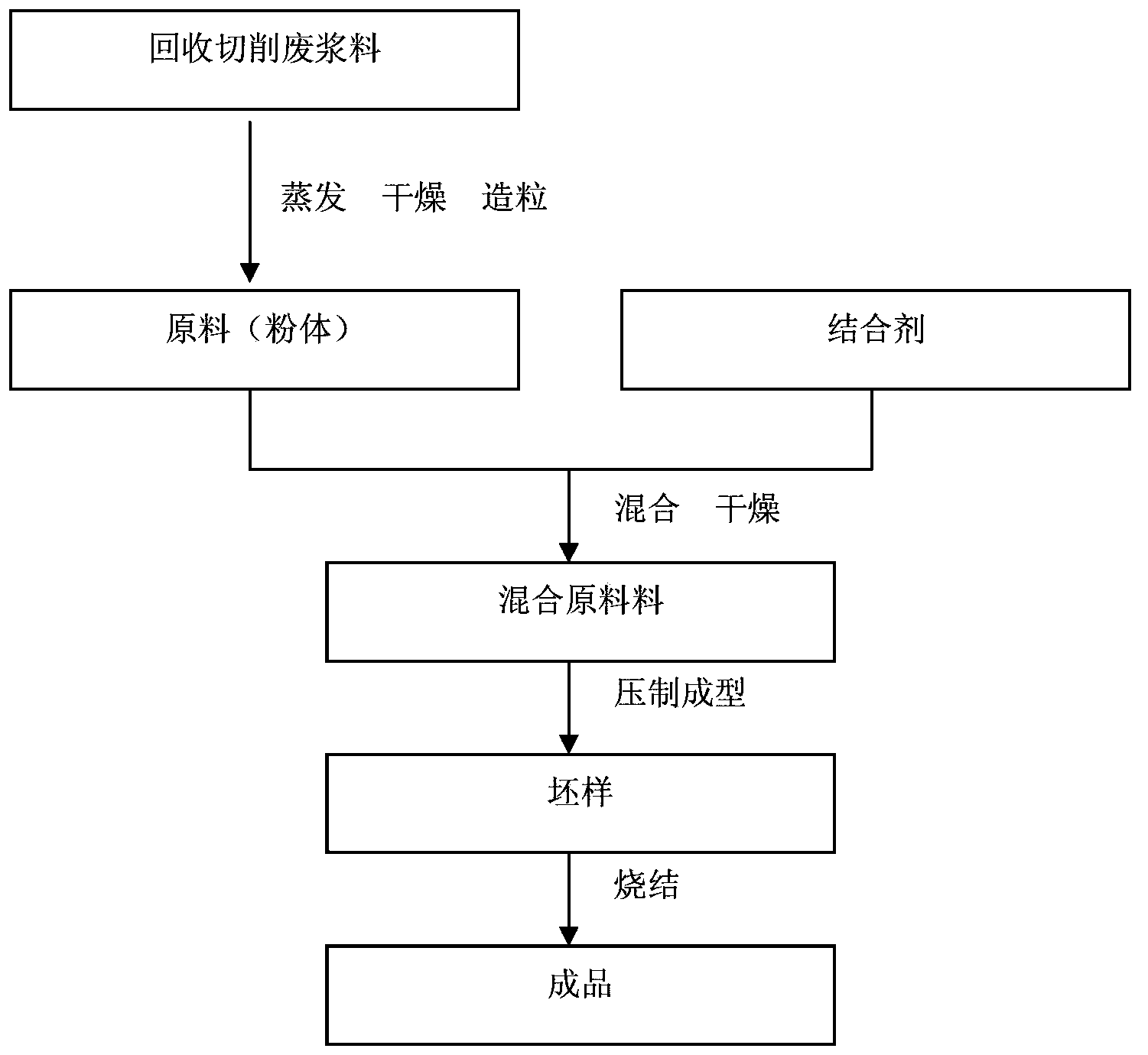

[0023] The preparation steps of Si-B-C-N material are as follows:

[0024] In the first step, 10% of metal Si with a particle size of 1000 mesh to 1500 mesh, 80% of SiC with a particle size of 1000 mesh to 1500 mesh, and 8% of B with a particle size of 1000 mesh to 1500 mesh 4 C, 2% graphite and 5% of the total mass fraction of the binder are mixed together, ball milled for a total of 2 hours, 1 hour for each front and back;

[0025] The second step is to use a DY-30 hydraulic press 10MP to press the raw material powder into a green body, dry at 200°C for 1 hour, and stand at room temperature for 48 hours;

[0026] The third step is to place the green body in a nitriding furnace for nitriding sintering. The sintering rate is 8°C / min from 0°C to 900°C, 5°C / min from 900°C to 1050°C, and 2°C / min from 1050°C. To 1300°C, 5°C / min from 1300°C to 1400°C, hold at 1400°C for 4 hours, 2°C / min from 1400°C to 1050°C, and then naturally cool down to room temperature.

Embodiment 2

[0028] The preparation steps of Si-B-C-N material are as follows:

[0029] In the first step, 30% of metal Si with a particle size of 1000 mesh to 1500 mesh, 60% of SiC with a particle size of 1000 mesh to 1500 mesh, and 8% of B with a particle size of 1000 mesh to 1500 mesh 4 C, 2% graphite and 5% of the total mass fraction of the binder are mixed together, ball milled for a total of 2 hours, 1 hour for each front and back;

[0030] The second step is to use a DY-30 hydraulic press 10MP to press the raw material powder into a green body, dry at 200°C for 1 hour, and stand at room temperature for 48 hours;

[0031] The third step is to place the green body in a nitriding furnace for nitriding sintering. The sintering rate is 8°C / min from 0°C to 900°C, 5°C / min from 900°C to 1050°C, and 2°C / min from 1050°C. To 1300°C, 5°C / min from 1300°C to 1400°C, hold at 1400°C for 4 hours, 2°C / min from 1400°C to 1050°C, and then naturally cool down to room temperature.

Embodiment 3

[0033] The preparation steps of Si-B-C-N material are as follows:

[0034] In the first step, 50% of metal Si with a particle size of 1000 mesh to 1500 mesh, 40% of SiC with a particle size of 1000 mesh to 1500 mesh, and 5% of B with a particle size of 1000 mesh to 1500 mesh 4 C, 5% graphite and a binder accounting for 5% of the total mass fraction are mixed together, ball milled for 2 hours, 1 hour for each front and back;

[0035] The second step is to use a DY-30 hydraulic press 10MP to press the raw material powder into a green body, dry at 200°C for 1 hour, and stand at room temperature for 48 hours;

[0036] The third step is to place the green body in a nitriding furnace for nitriding sintering. The sintering rate is 8°C / min from 0°C to 900°C, 5°C / min from 900°C to 1050°C, and 2°C / min from 1050°C. To 1300°C, 5°C / min from 1300°C to 1400°C, hold at 1400°C for 4 hours, 2°C / min from 1400°C to 1050°C, and then naturally cool down to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com