A kind of low-porosity magnesia-chrome brick applied in non-ferrous industry and production method thereof

A production method and technology of magnesia-chrome bricks are applied in the field of refractory materials, which can solve the problems of affecting the service life of bricks, reducing the performance of kilns, and entering refractory bricks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with embodiment the present invention is further described:

[0023] The following examples describe the present invention in detail. These examples are only to describe the best embodiment of the present invention, and do not limit the scope of the present invention.

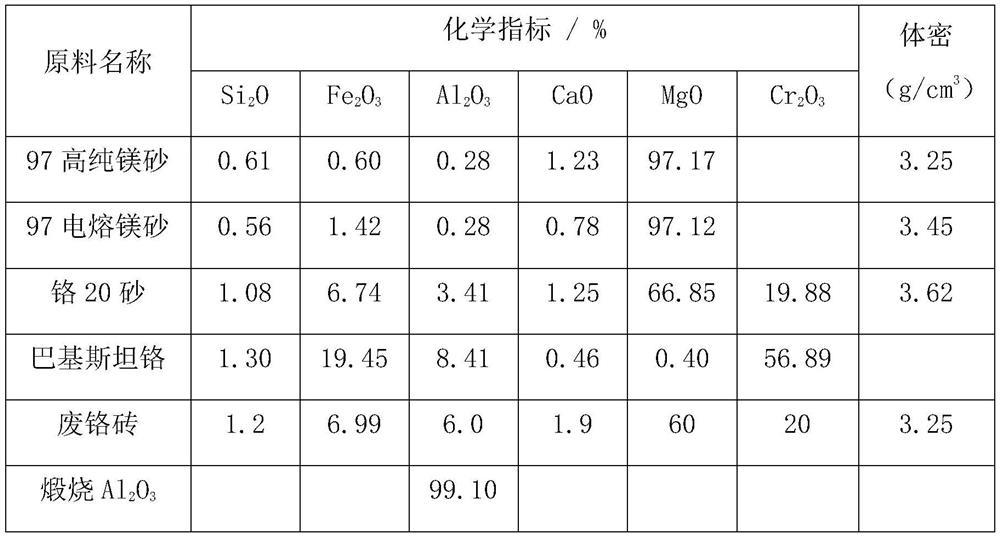

[0024] Table 1 Example 1-3 is the formula of low porosity magnesia chrome brick

[0025] ingredients Example 1 Example 2 Example 3 1-3mm 97 high-purity magnesia 2 copies 3 copies 5 copies 97 fused magnesia less than 0.074mm 10 copies 12 copies 5 copies 1-3mm 97 fused magnesia 15 copies 5 copies 10 copies 0-1mm chrome 20 sand 27 copies 35 copies 24 copies 1-3mm chrome 20 sand 10 copies 16 copies 20 copies 3-5mm chrome 20 sand 10 copies 20 copies 15 copies Pakistani chrome less than 0.074mm 8 servings 15 copies 18 copies Chrome 20 waste brick 14 copies 8 servings 10 copies al 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com