A parameter matching method for key components in a loader braking energy recovery regeneration system

A regenerative system and parameter matching technology, applied to the arrangement of multiple different prime movers of brakes, general power plants, motor vehicles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

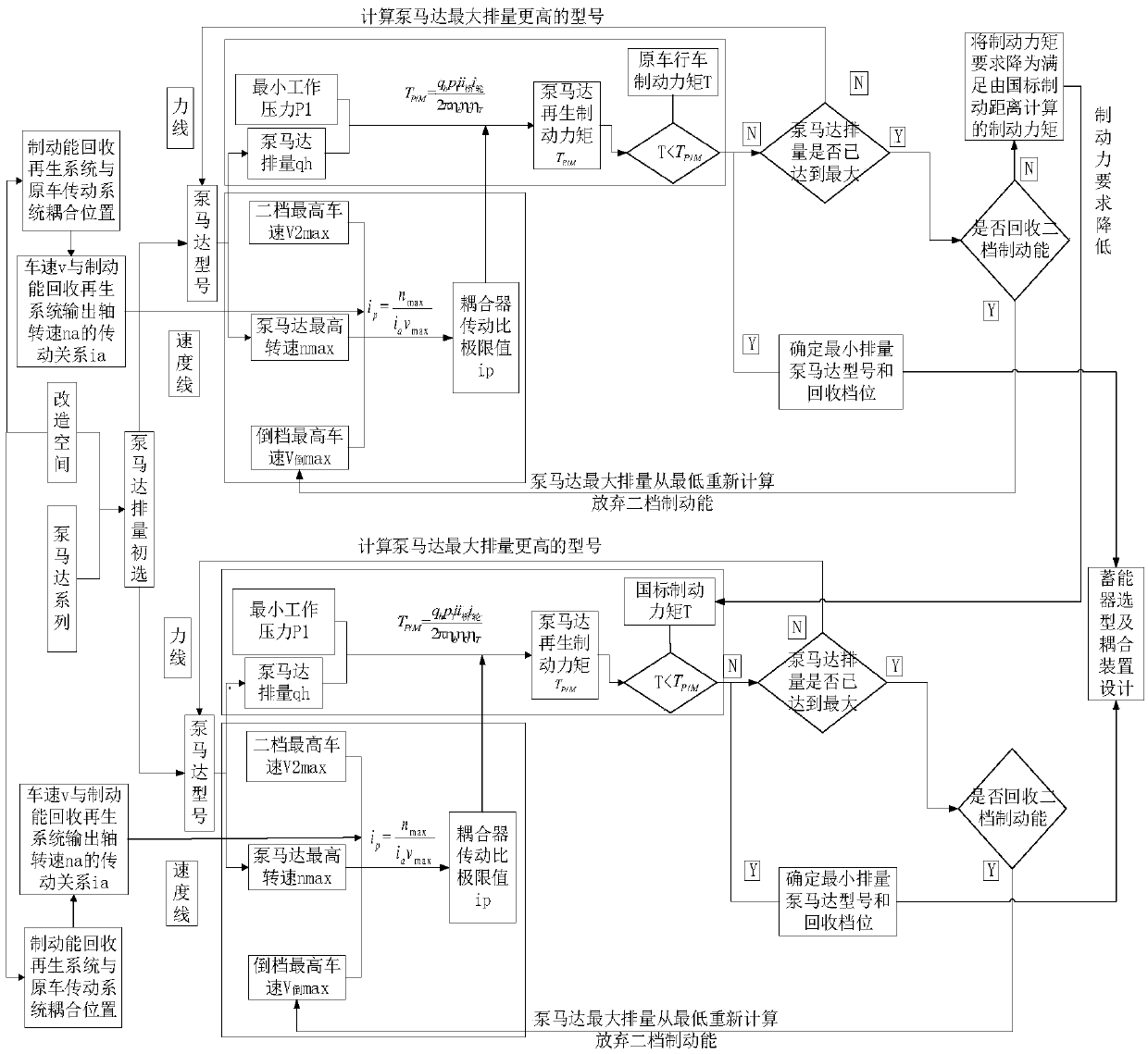

[0042] Loaders generally have three gears, including two forward gears and one reverse gear, and the speed of the second forward gear > the speed of the reverse gear > the speed of the first forward gear. We will describe the matching process based on this situation.

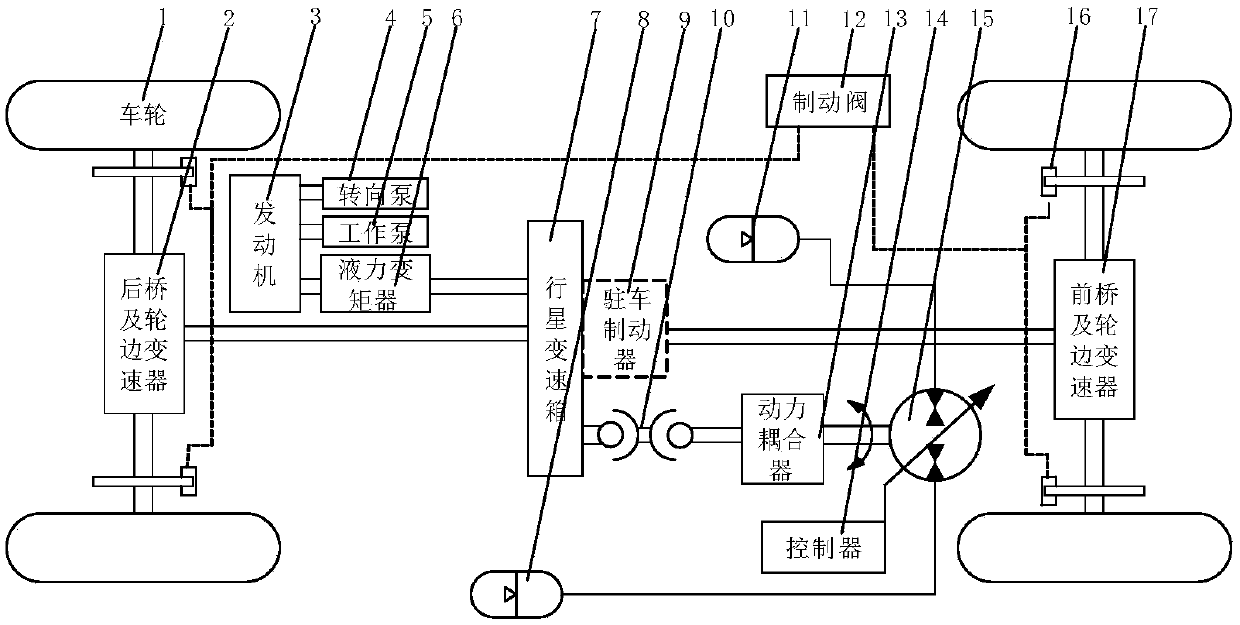

[0043] Such as figure 1 As shown, wheel 1, rear axle and wheel reducer 2, engine 3, steering pump 4, working pump 5, hydraulic torque converter 6, planetary gearbox 7, low pressure accumulator 8, parking brake 9, million Knuckle 10, accumulator 11, brake valve 12, power coupler 13, controller 14, pump motor 15, caliper brake 16, front axle and wheel reducer 17 is a parallel hydraulic hybrid loader When the loader is running normally, the power of the engine 3 is transmitted to the steering pump 4, the working pump 5 and the hydraulic torque converter 6 respectively, and the power of the hydraulic torque converter 6 is transmitted to the planetary gearbox 7, and then through The front axle and wheel reducer 17 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com