A deep sea high pressure dry maintenance device

A high-pressure, dry technology, used in transportation and packaging, ships, underwater operation equipment, etc., can solve the problem of increasing the complexity and danger of underwater maintenance operations, maintenance personnel in a dry environment throughout the process, and underwater operations. Short time and other problems, to achieve the effect of long-term underwater operation, shortening the operation cycle and prolonging the operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be described below.

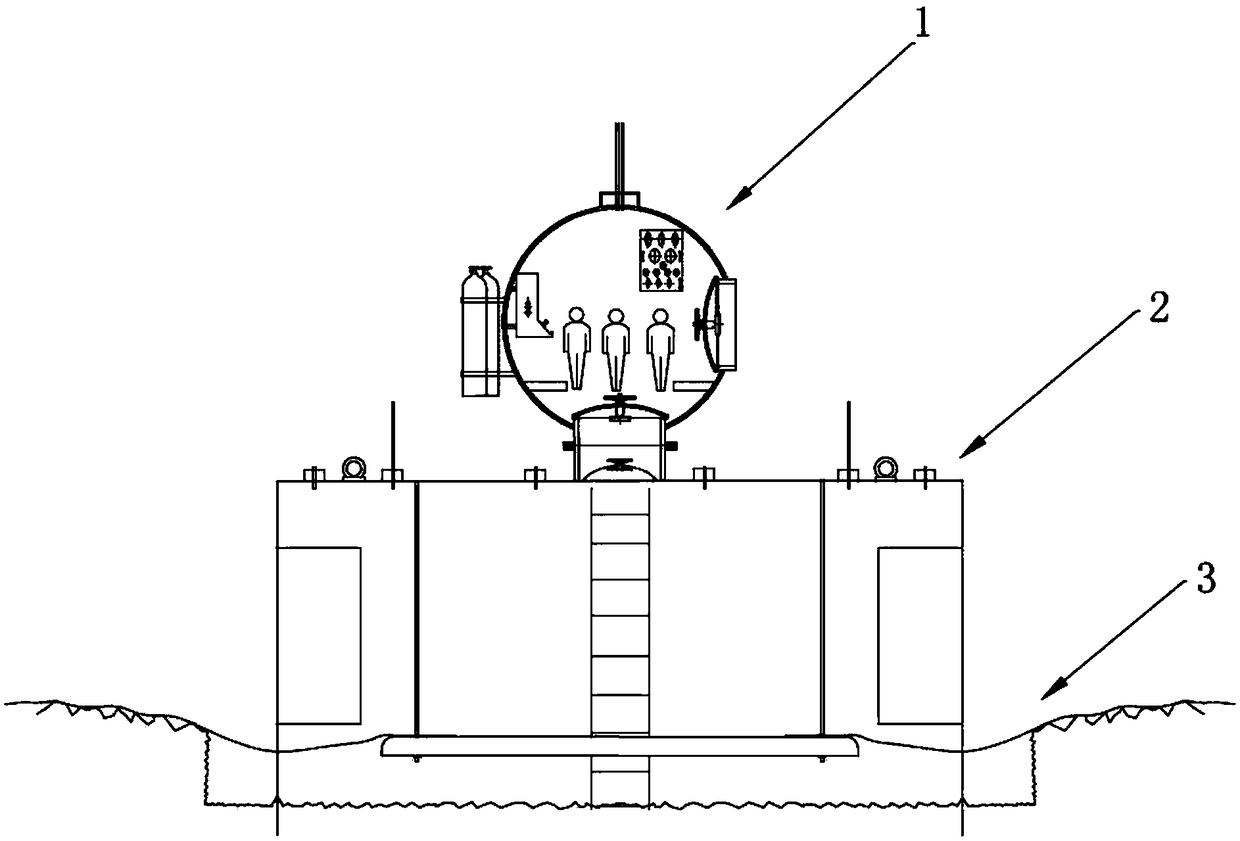

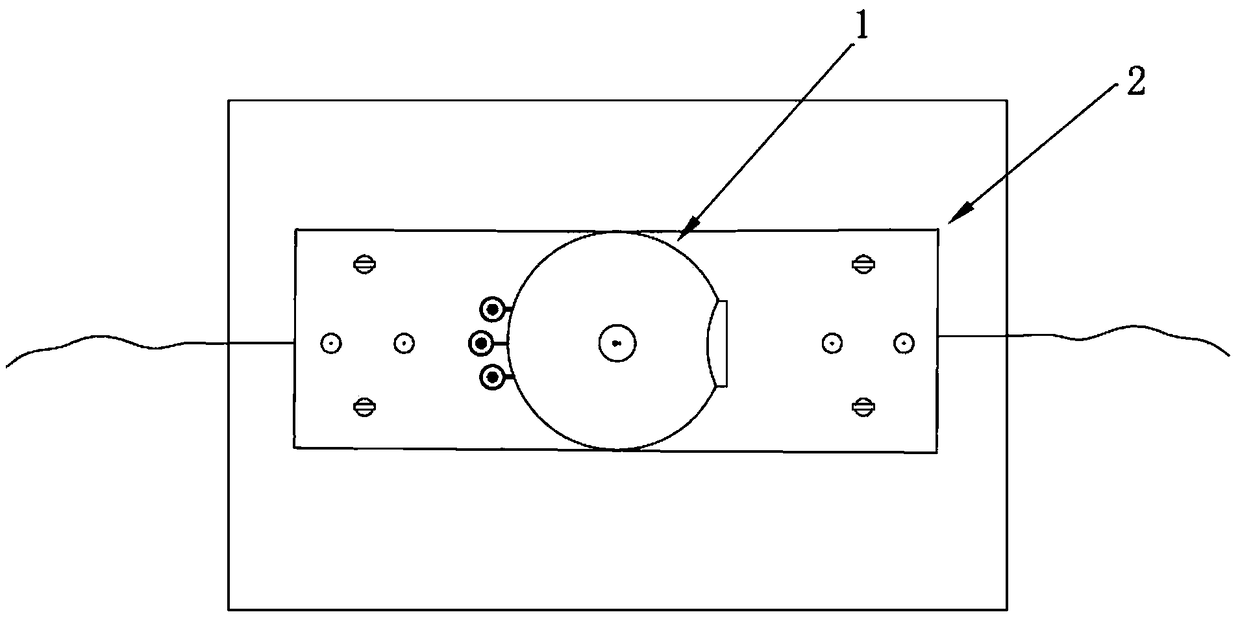

[0029] Such as figure 1 , figure 2 As shown, a deep-sea high-pressure dry maintenance device includes a diving bell 1, and one end of the diving bell 1 is airtightly or watertightly connected with a high-pressure dry maintenance cabin 2;

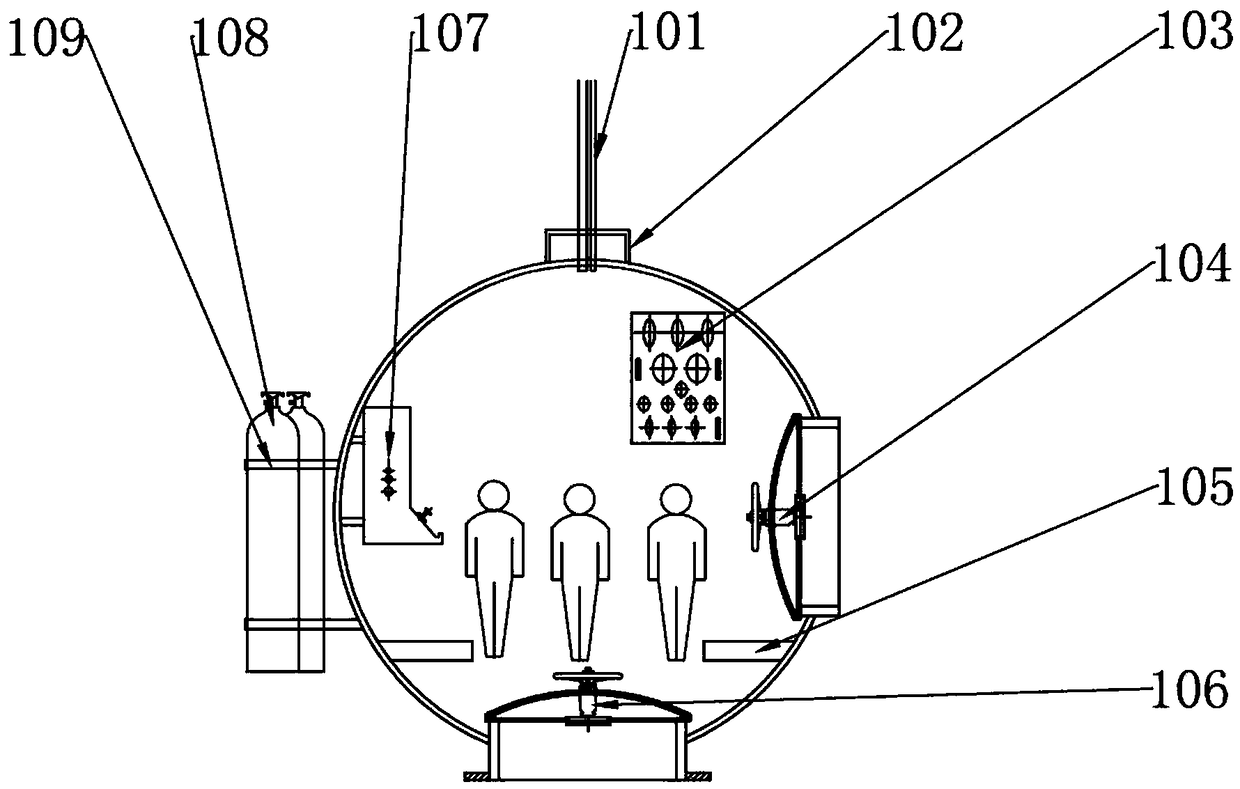

[0030] Such as image 3 As shown, the specific structure of the above-mentioned diving bell 1 is as follows: it includes a housing with an inner cavity, and a cable connector 102 is arranged at one end of the outer periphery of the housing, and the cable connector 102 is connected to one end of the cable assembly 101, and the cable assembly 101 The other end of the other end is connected with the mother ship to provide high-pressure heliox gas mixture, energy supply and information communication for the personnel in the shell; the life support system panel 103 for monitoring the life status of the maintenance personnel is respectively arranged in the inner cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com