Material sorting system

A sorting system and feeding system technology, applied in the direction of conveyor objects, conveyor control devices, conveyors, etc., can solve problems such as low efficiency, less error-prone, and increased sorting difficulty, so as to improve sorting efficiency, The error rate is small and the effect of reducing the labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

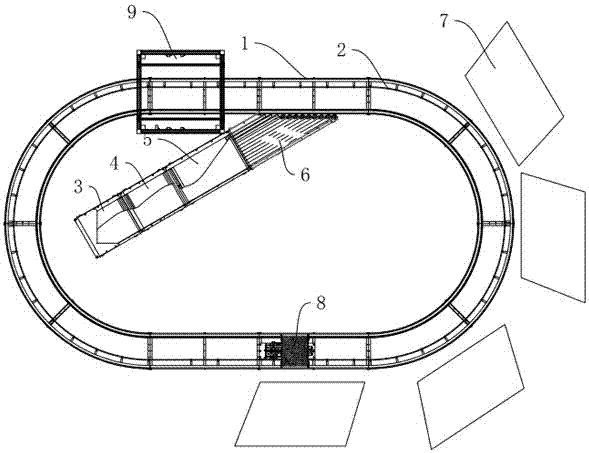

[0025] Embodiment: a kind of material sorting system (referring to figure 1 ), including: a transport trolley system with multiple transport trolleys capable of accepting items, a feeding system that transmits items to the transport trolley 8, a transmission system that drives the transport trolleys to move cyclically, and multiple discharge platforms that undertake the discharge of items 7. And the control system for processing item information, controlling the feeding of the feeding table, controlling the movement and discharging of the transport trolley.

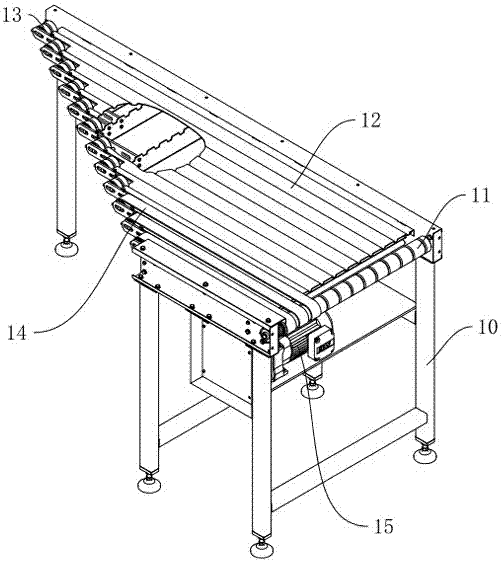

[0026] The feeding system transfers the item packaging to the delivery trolley. The feeding system includes the coding section 3 for collecting item information, the measurement section 4 for measuring the size and weight of the item packaging, and the speed up of the item packaging to the speed of the delivery trolley. A matching acceleration section 5 and a loading section 6 that transfers the item packages from the fee...

Embodiment 2

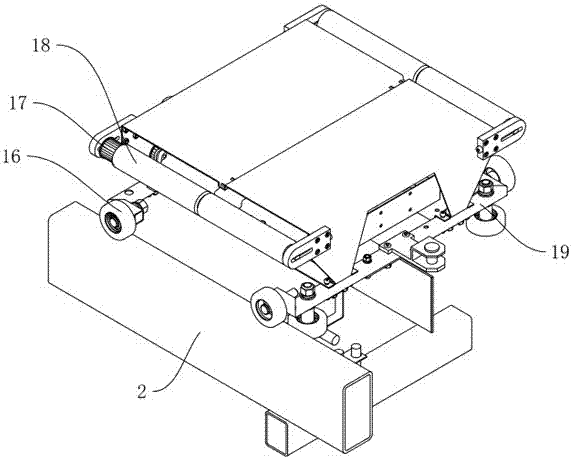

[0032] Embodiment 2: A material sorting system, the difference from Embodiment 1 is that the bracket is made of multiple modules spliced together, each module matches the size of the transport trolley, and the number of modules is equal to the number of transport trolleys . Each module is equipped with a mobile positioning device for the transport trolley. The positioning device can control the operation of the servo motor of the transport trolley. When the items loaded on the transport trolley move to the corresponding position of the discharge platform, the positioning device will give a corresponding signal, and the servo motor will rotate to quickly transfer the items to the discharge platform. Refer to Example 1 for all the other structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com