Gravity driven ultrafiltration biomembrane reactor device and method for treating low-temperature low ammonia nitrogen waste water

A biofilm reactor, gravity-driven technology, applied in sustainable biological treatment, biological water/sewage treatment, chemical instruments and methods, etc. The effect of low membrane fouling, long operation cycle and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

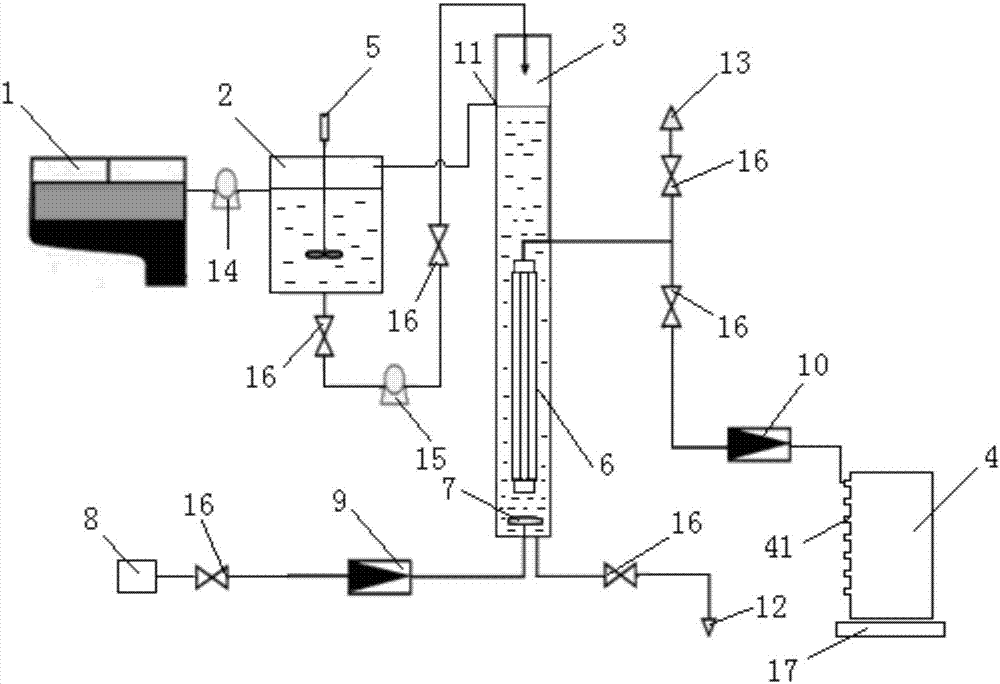

[0036] Specific Embodiment 1: In this embodiment, a gravity-driven ultrafiltration biofilm reactor device includes a stock solution tank 1, a water storage tank 2, a reaction tank 3, a collection tank 4, a stirring paddle 5, a membrane module 6, an aeration head 7, Air pump 8, gas flowmeter 9, liquid flowmeter 10, overflow port 11, sewage outlet 12, exhaust port 13, first water pump 14, second water pump 15, multiple valves 16, multiple water inlets 41 and electronic balance 17;

[0037] The water outlet of the stock solution tank 1 is connected with the water inlet of the first water pump 14 through a pipeline, and the water outlet of the first water pump 14 is connected with the water inlet of the water storage tank 2 through a pipeline;

[0038] A stirring paddle 5 is arranged in the water storage tank 2;

[0039] The water outlet of the water storage tank 2 is connected to the water inlet of the second water pump 15 through a pipeline, and a valve 16 is arranged on the pipe...

specific Embodiment approach 2

[0048] Embodiment 2: This embodiment differs from Embodiment 1 in that: the water inlet of the reaction pool 3 is set at the top or bottom of the reaction pool 3 . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0049] Embodiment 3: This embodiment is different from Embodiment 1 in that: the agitating paddle 5 is a jacking type agitating paddle. Others are the same as in the first or second embodiment.

[0050] The stirring paddle 5 in this embodiment is controlled by a motor, and is suitable for low-velocity and low-viscosity fluids in a suspended state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com