Catalytic cracking catalyst production wastewater pretreatment system and method

A technology for producing waste water and catalytic cracking, which is applied in chemical instruments and methods, water/sewage treatment, neutralized water/sewage treatment, etc., and can solve problems such as high energy consumption of biochemical treatment devices, poor sewage water quality, and large alkalinity consumption , to achieve the effect of increasing the speed of biochemical treatment, reducing the cost of treatment, and reducing the hardness of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: A catalytic cracking catalyst production wastewater pretreatment system, including a sedimentation tank, an electrolytic oxidation tank and a sand filter connected in sequence. The electrolytic oxidation cell has a built-in electrocatalytic oxidation device. The anode of the electrocatalytic oxidation device is a ruthenium iridium titanium anode plate, and the cathode is a titanium plate. The distance between the anode plates is 1.5cm, and the plate voltage is 4V-8V.

Embodiment 2

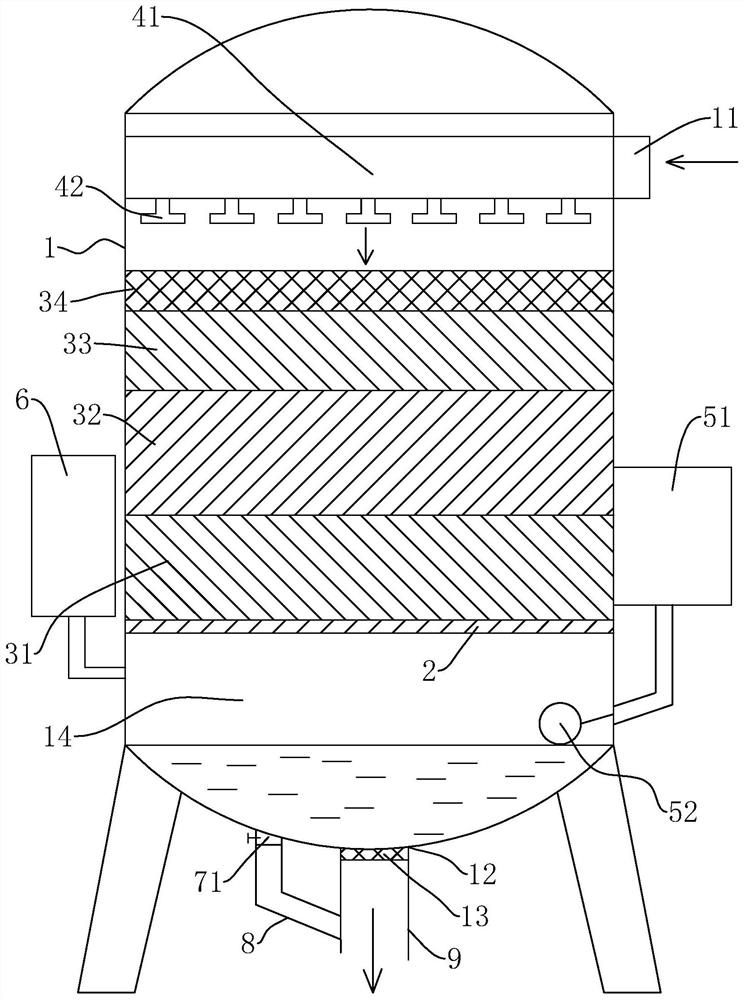

[0021] Embodiment 2: The sand filter includes a tank body 1, a water inlet 11 located at the upper end of the tank body 1, and a water outlet 12 located at the bottom of the tank body 1. The water outlet 12 is provided with a flow blocking net 13, and the inside of the tank body 1 A support net 2 is fixed at the bottom, and a gravel support layer 31, a coarse sand layer 32, a fine sand layer 33, and anthracite layer 34 are sequentially arranged above the support net 2 from bottom to top, and the water inlet 11 is connected to a horizontally arranged cloth A water pipe 41, the water distribution pipe 41 is connected with a plurality of water distributors 42; the support net 2 and the bottom of the tank body 1 form a buffer space 14, and the two sides of the tank body 1 are respectively connected with a water supply tank 51 and a vacuum pump 6, Both the water replenishment tank 51 and the vacuum pump 6 are in communication with the buffer space 14 , the buffer space 14 is provide...

Embodiment 3

[0025] Embodiment 3: a kind of catalytic cracking catalyst production waste water pretreatment method, comprises the following steps successively: 1) waste water enters sedimentation tank, adds caustic soda in sedimentation tank, regulates sewage pH value 8, drops into soda ash again to make the calcium and magnesium in sewage Calcium and magnesium ions generate Mg(OH) 2 and CaCO 3 Sedimentation, the wastewater stays in the sedimentation tank for 40 minutes;

[0026] 2) The wastewater passing through the sedimentation tank enters the electrolytic oxidation tank. The electrolytic oxidation tank has a built-in electrocatalytic oxidation device. The anode of the electrocatalytic oxidation device is a ruthenium iridium titanium anode plate, and the cathode is a titanium plate. The distance between the anode plates is 1.5cm, and the plate voltage is 5V. Residence time 60min;

[0027] 3) The wastewater passing through the electrolytic oxidation tank enters the sand filter, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com