Full-automatic fiber turntable micro-filter for deep sewage disposal

A technology of fiber turntable and advanced treatment, which is applied in the direction of mobile filter element filter, filter separation, filter circuit, etc., which can solve the problems of shortening the service life of filter cloth equipment, reducing the service life of pipeline system, and high requirements for automatic control, so as to achieve improvement The service life and the quality of the effluent water, the effect of solving the problem of unreliable edge pressing and cleaning thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is further described below in conjunction with specific embodiments.

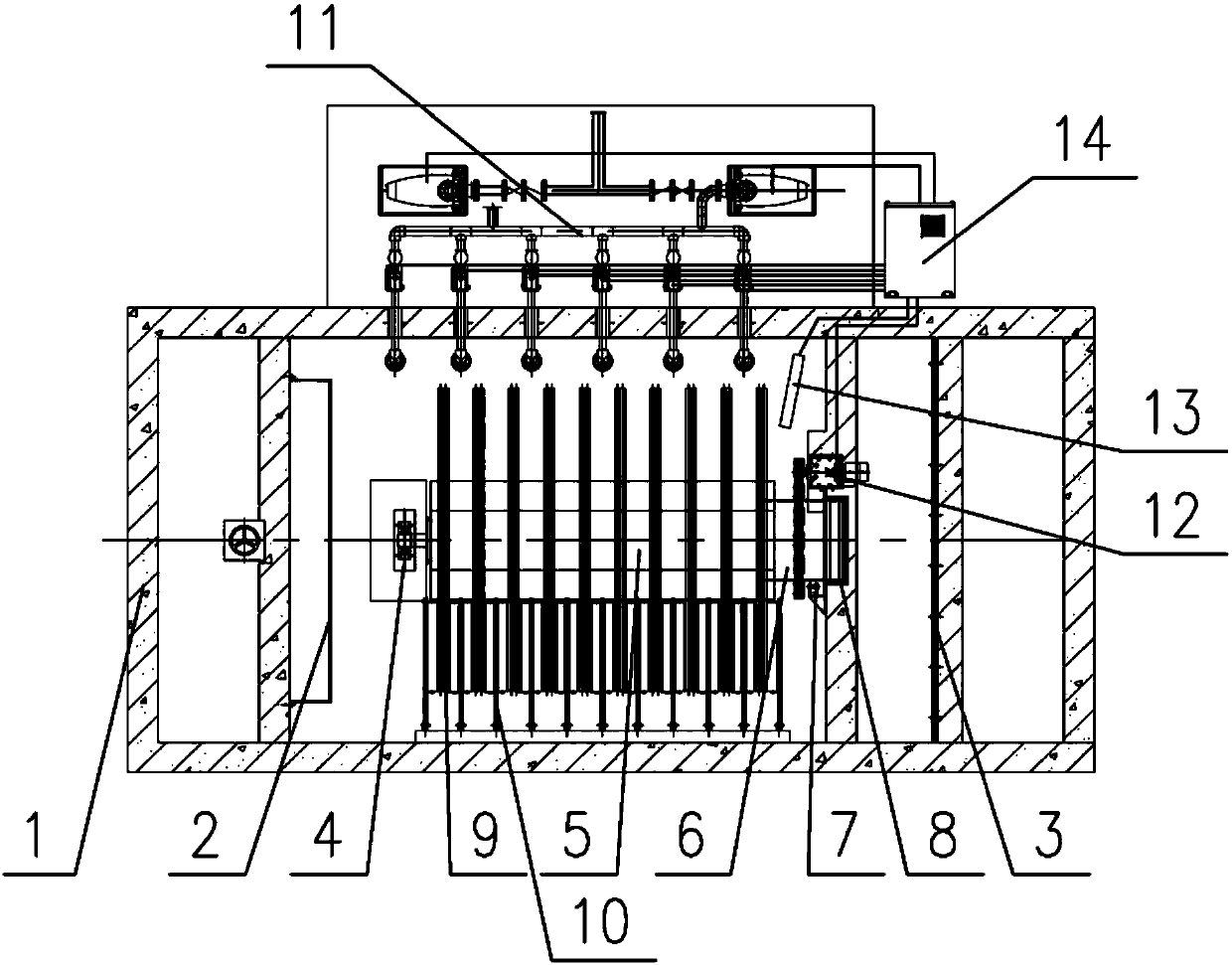

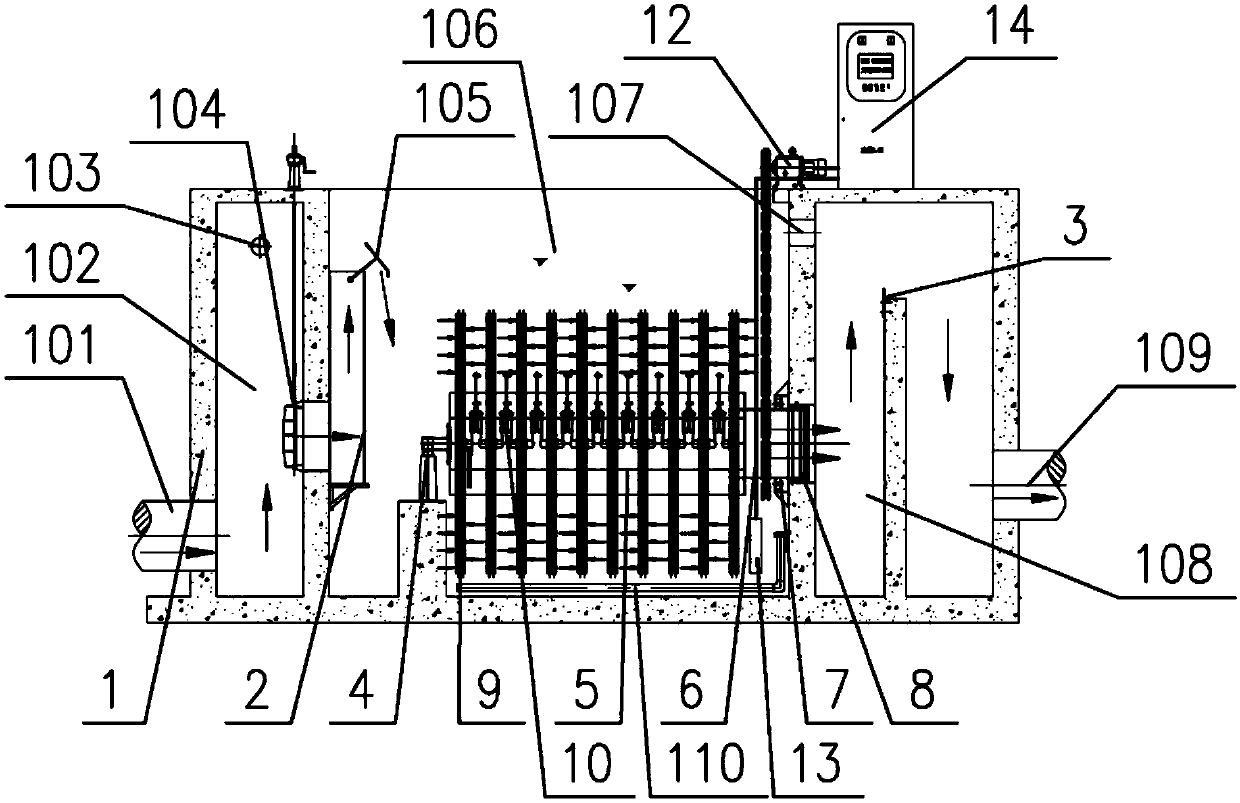

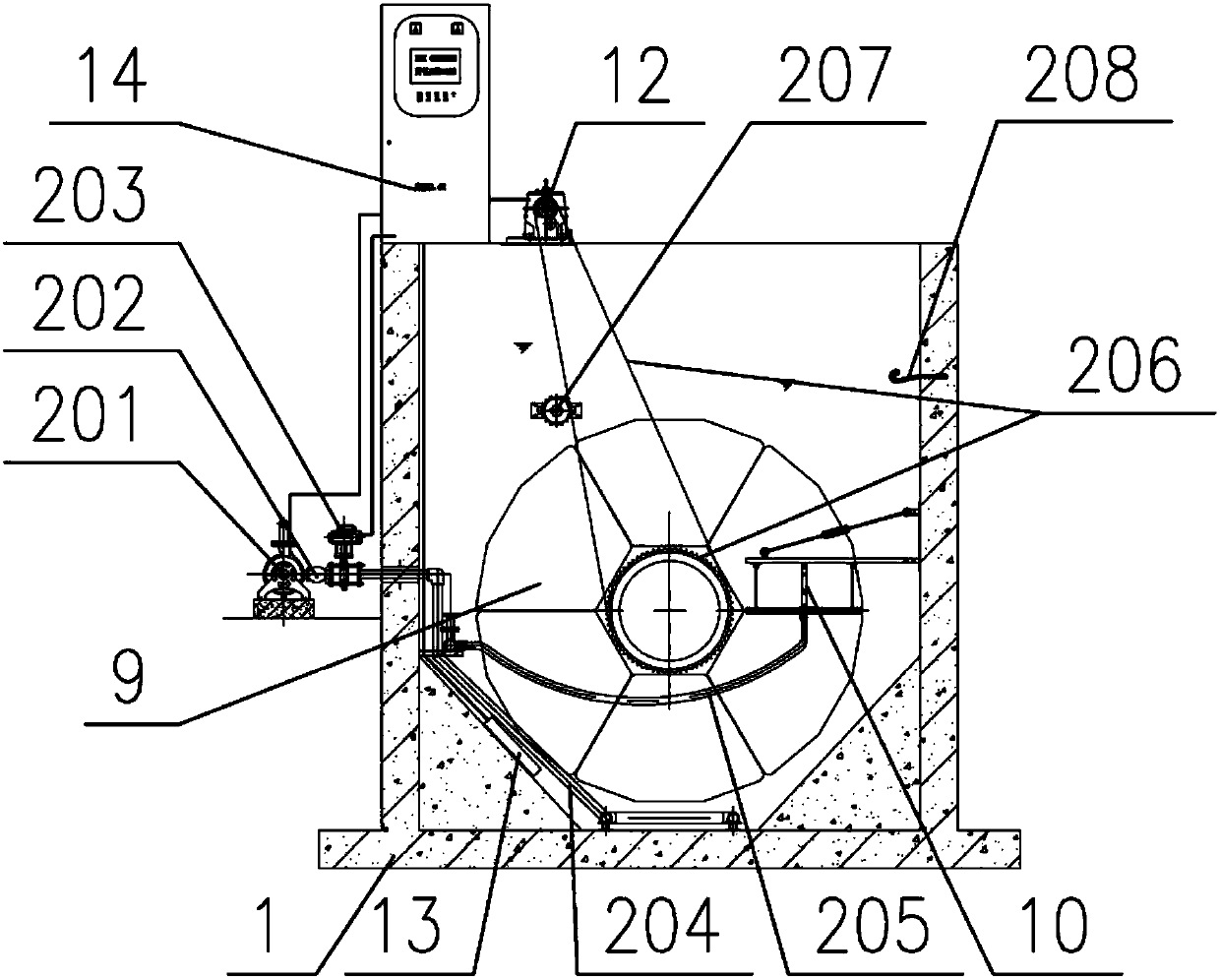

[0043] A full-automatic fiber turntable microfiltration machine for advanced sewage treatment, including steel-concrete tank body (1), water inlet weir box (2), water outlet adjustable weir plate (3), end support seat (4), hollow, etc. Side hexagonal cylinder (5), water outlet pipe (6), water outlet support pulley (7), water outlet sealing assembly (8), sewage system (11), driving device (12), automatic control system (14).

[0044]The blowdown system (11) includes a backsuction pump (201) supporting shrinkage, a check valve (202), a solenoid valve (203), a bottom blowdown pipe (204), a fiber turntable (9) blowdown pipe (205), And backwashing device (10).

[0045] Wherein: the end of the hollow equilateral hexagonal cylinder (5) is provided with a shaft and connected with the end support seat (4); the hollow equilateral hexagonal cylinder (5) is connected with the outlet pipe (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com