Two-component epoxy asphalt emulsion material and preparation method thereof

A technology of epoxy asphalt and epoxy resin emulsion, which is applied in the direction of building insulation materials, building components, buildings, etc. It can solve the problems of not changing the thermoplastic properties of asphalt, high temperature stability and bonding performance, which are difficult to meet the specification requirements and affect the application. , to achieve excellent high temperature stability and low temperature crack resistance, wide market application prospects and social benefits, high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0027] 70A# asphalt was purchased from Sinopec Jinling Petrochemical Co., Ltd.

[0028] 90A# asphalt was purchased from Sinopec Jinling Petrochemical Co., Ltd.

[0029] 1831 emulsifier was purchased from Guanghan Rongxin Fine Chemical Co., Ltd.

[0030] 1631 emulsifier was purchased from Guanghan Rongxin Fine Chemical Co., Ltd.

[0031] Epoxy resin emulsion CYDW-100 was purchased from Epoxy Resin Division of Sinopec Baling Petrochemical Branch

[0032] Epoxy resin emulsion CYDW-102W50 was purchased from Epoxy Resin Division of Sinopec Baling Petrochemical Branch

[0033] T-06-G curing agent emulsion was purchased from Anhui Legend New Material Co., Ltd.

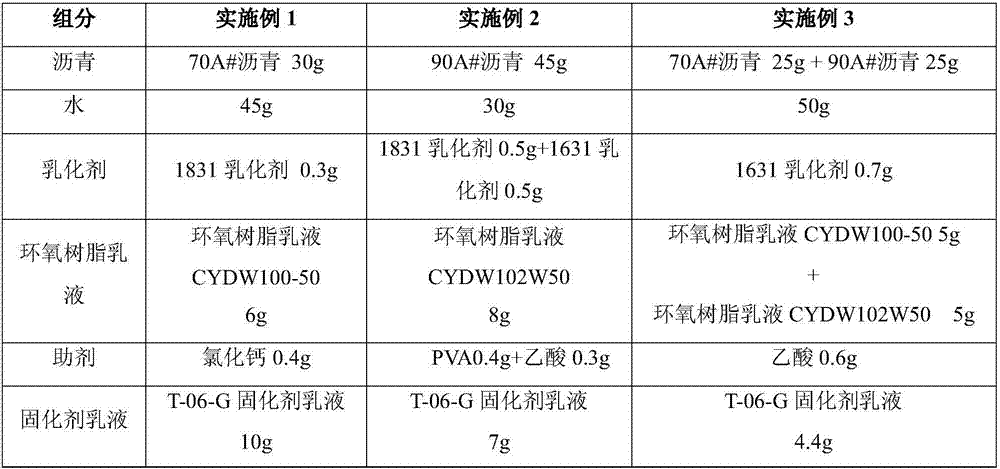

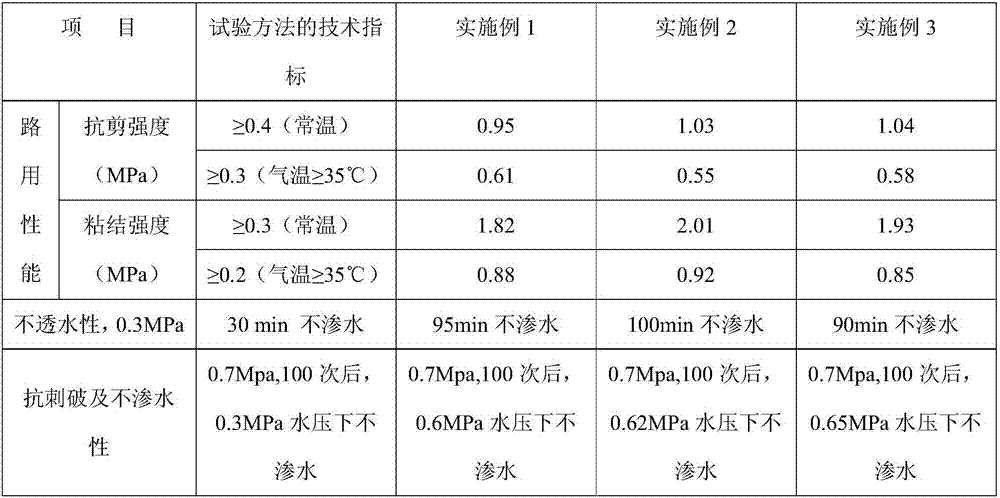

[0034] Components used in Examples 1 to 3 of the present invention and their consumption are shown in Table 1

[0035] Table 1

[0036]

Embodiment 1

[0037] The preparation method of embodiment 1 two-component epoxy asphalt emulsion material:

[0038] (1) Add the emulsifier into water at 50°C and stir evenly, then add epoxy resin emulsion and additives and stir again evenly to obtain the mixed liquid a;

[0039] (2) adding pitch with a temperature of 80°C to the mixed solution a described in step (1) and mixing evenly to obtain mixed solution b;

[0040] (3) Add curing agent emulsion into mixed solution b and stir evenly.

Embodiment 2

[0041] The preparation method of embodiment 2 two-component epoxy asphalt emulsion material:

[0042] (1) Add the emulsifier into water at 70°C and stir evenly, then add epoxy resin emulsion and additives and stir evenly again to obtain the mixed solution a;

[0043] (2) adding bitumen at a temperature of 100°C to the mixed solution a described in step (1) and mixing evenly to obtain the mixed solution b;

[0044] (3) Add curing agent emulsion into mixed solution b and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com