Large-diameter shield tunnel concrete segment connecting construction

A technology for shield tunnels and concrete pipes, which is applied to tunnels, tunnel linings, earth-moving drilling and mining, etc., can solve the problems of difficulty in taking into account durability and assembling convenience, inconvenient design and use of vacuum suction cups, and unclear force system, etc. Intuitive and easy to judge, the force system is clear, and the durability is reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

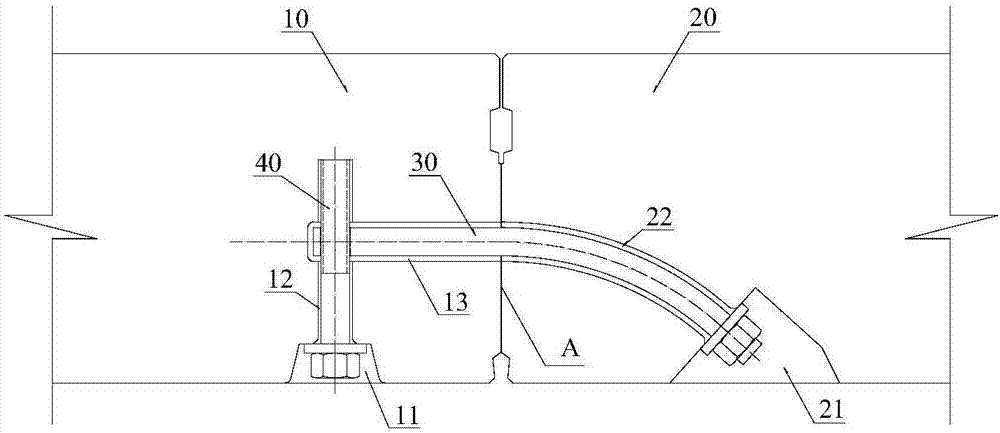

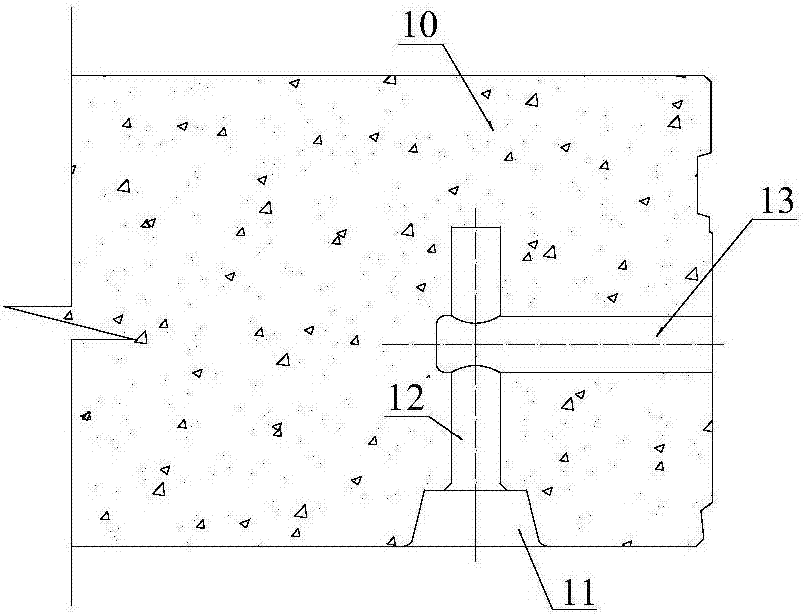

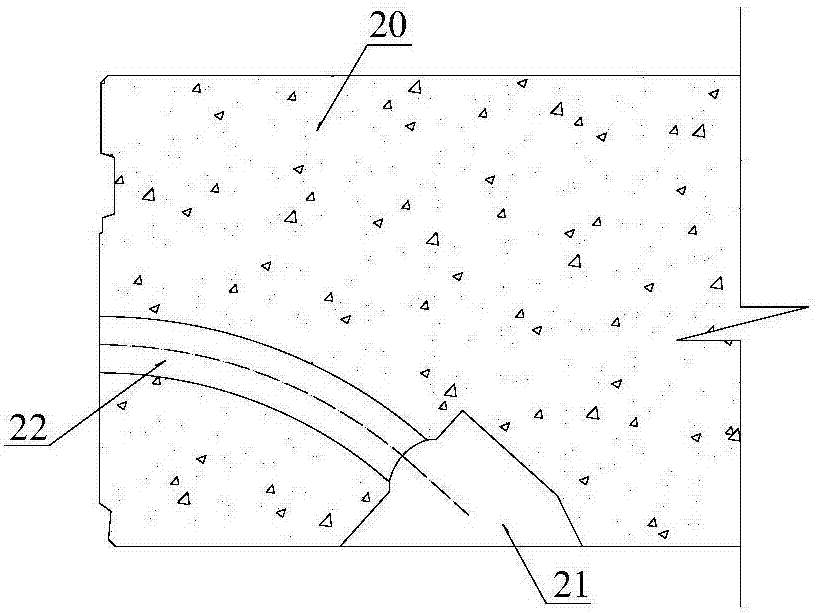

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] Figure 7 It is a vertical section view of the existing shield tunnel concrete segment connection structure. A hand hole 72 is set on the inner arc surface of the first concrete segment 10. The inner end of the straight hole 73 is connected with the hand hole 72, and the outer end is connected with the first concrete segment. The end walls of the joint A side of the concrete segment 10 are connected. On the other side of the seam A, a pre-embedded casing 71 is arranged in the second concrete segment 20 along the axis of the straight hole 73 . The oblique connecting bolt 70 passes through the straight hole 73 through the hand hole 72, and its rear part is screwed with the embedded casing 71. This connection structure has the following three deficiencies: First, due to the difficulty of demoulding and assembly, the embedded sleeve 71 is generally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com