Electric vehicle extend range power improved type membrane type carburetor

A diaphragm type carburetor and carburetor technology, applied in carburetors, engine components, machines/engines, etc., can solve problems such as poor oil supply of carburetors, avoid changes in physical properties, and achieve good control The effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

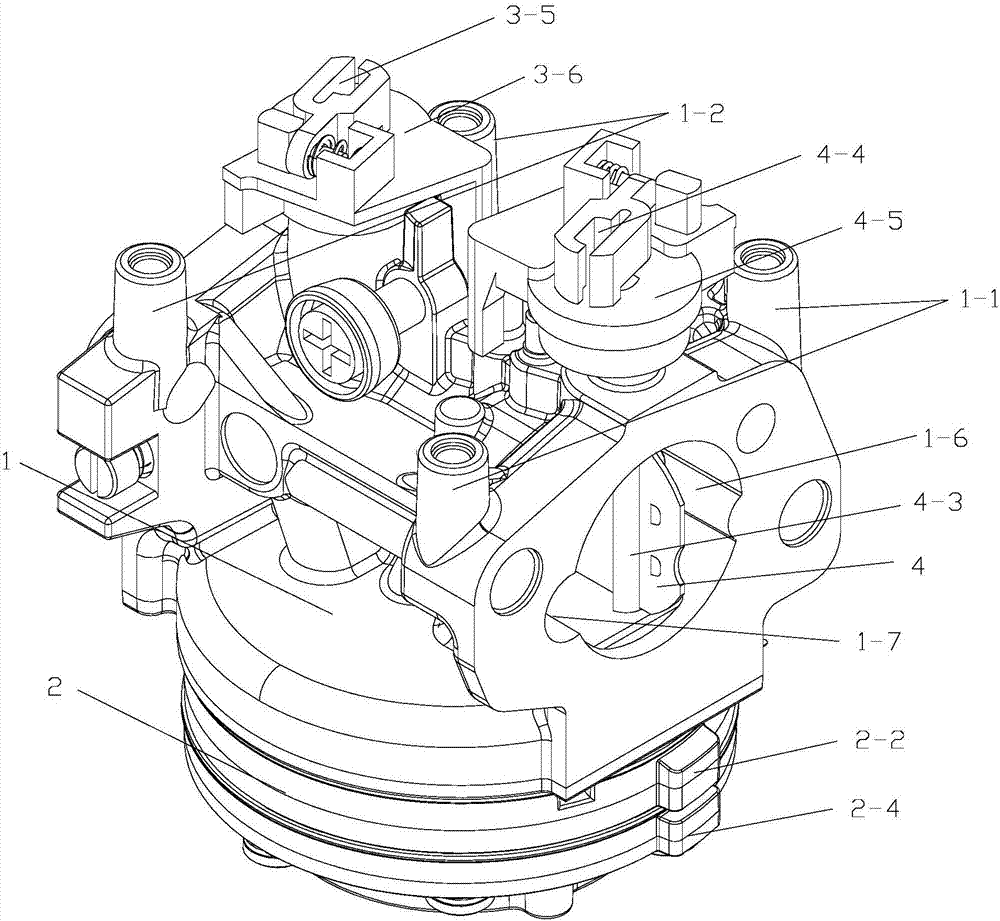

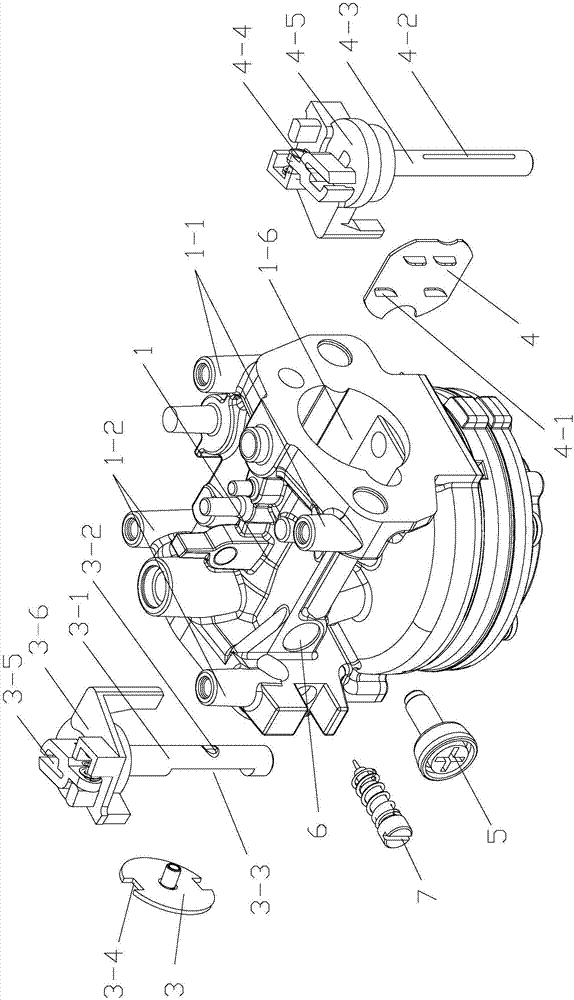

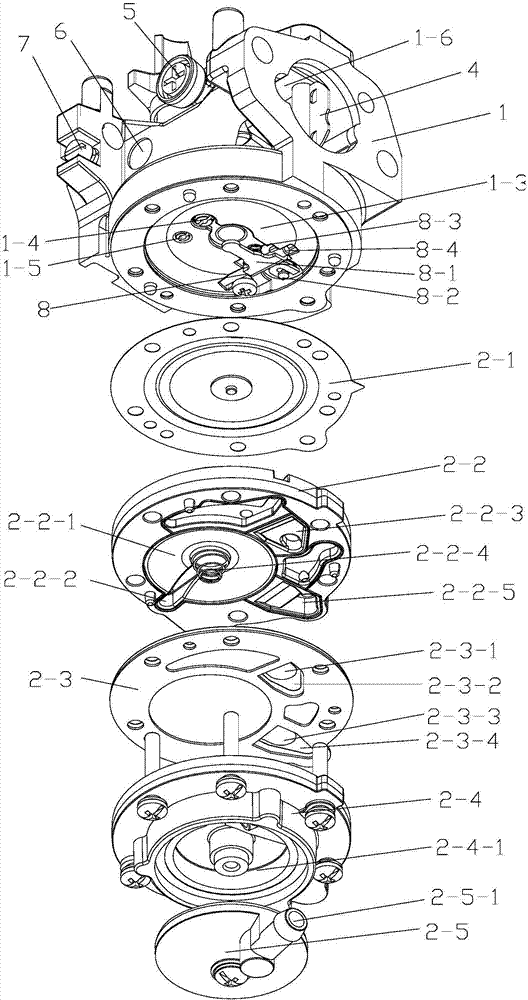

[0036] Such as Figure 1~6 As shown, this embodiment provides an improved diaphragm type carburetor for electric vehicle range-extended power through two stepping motors to control the rotation of the choke valve and the throttle valve respectively, including a carburetor body 1, the carburetor The upper body of the carburetor body 1 is provided with an air intake channel 1-6 that runs through the carburetor body 1, and the air intake channel 1-6 is sequentially provided with a choke valve 4 that can rotate to adjust the intake air volume along the air intake direction. The throat pipe 1-10 for accelerating the air flow speed and the throttle valve 3 that can be rotated to adjust the amount of mixed gas, the lower side of the carburetor body 1 is provided with a fuel injection chamber 1-3 for storing fuel, and the carburetor body 1 is provided with a fuel injection passage for spraying the fuel in the fuel injection chamber 1-3 to the air intake passage 1-6, and the lower part...

Embodiment 2

[0042] Such as Figure 7 or Figure 8 As shown, this embodiment provides an improved diaphragm type carburetor for electric vehicles with extended range and power controlled by a stepping motor, which includes a carburetor body 1, and the upper part of the carburetor body 1 is set in the body There are air intake passages 1-6 that run through the carburetor body 1, and the air intake passages 1-6 are sequentially provided with a choke valve 4 that can rotate to adjust the intake air volume along the air intake direction, and a valve for accelerating the air flow velocity. Throat 1-10 and throttle valve 3 that can be rotated to adjust the amount of mixed gas. The lower side of the carburetor body 1 is provided with a fuel injection chamber 1-3 for storing fuel. The fuel in the fuel injection chamber 1-3 is sprayed to the fuel injection passage in the intake passage 1-6, and the lower part of the carburetor body 1 is equipped with a negative pressure for controlling the fuel ta...

Embodiment 3

[0047] This embodiment provides an electric vehicle range-extending power improved diaphragm carburetor that controls the rotation of the throttle valve through a stepping motor, including a carburetor body 1, and the upper body of the carburetor body 1 is provided with a penetrating carburetor. The air intake channel 1-6 of the oiler body 1, the air intake channel 1-6 is sequentially provided with a choke valve 4 that can be rotated to adjust the intake air volume, and a throat pipe 1 for accelerating the air flow speed along the air intake direction. -10 and the throttle valve 3 that can be rotated to adjust the amount of mixed gas, the lower side of the carburetor body 1 is provided with a fuel injection chamber 1-3 for storing fuel, and the carburetor body 1 is provided with a fuel injection chamber for making The fuel in 1-3 is sprayed to the fuel injection passage in the intake passage 1-6, and the lower part of the carburetor body 1 is equipped with a negative pressure a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com