Pressurization oil tank for injection molding machine

A pressurized oil tank and injection molding machine technology, applied in the direction of oil supply tank devices, mechanical equipment, fluid pressure converters, etc., can solve the problems of self-priming of oil pumps that cannot meet the standards, achieve optimized oil suction pipe diameter, reduce noise, and simple and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below with reference to the drawings and embodiments.

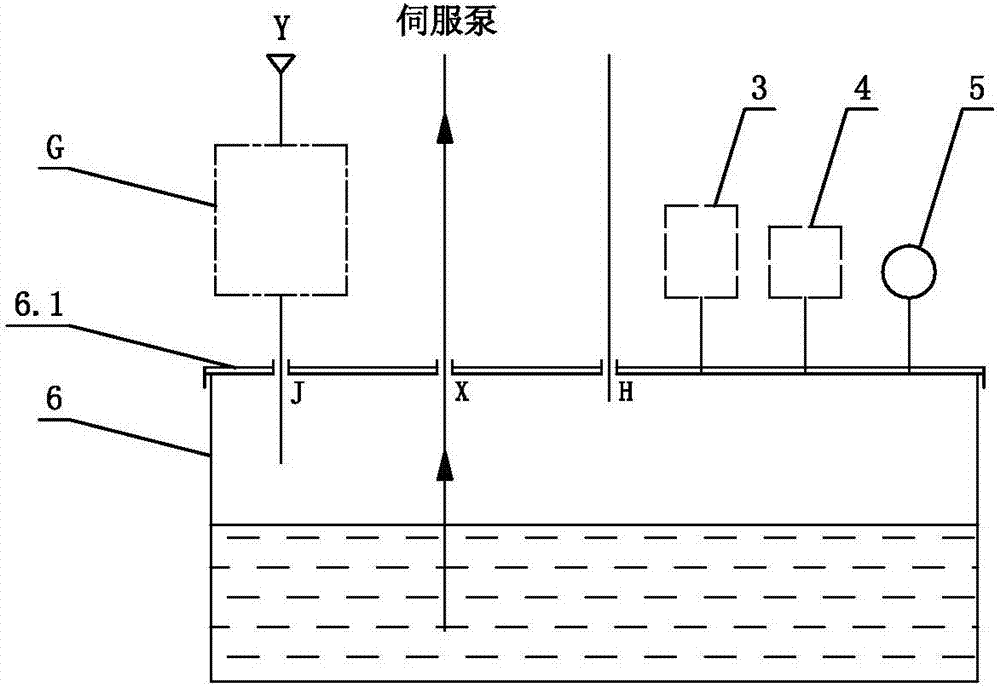

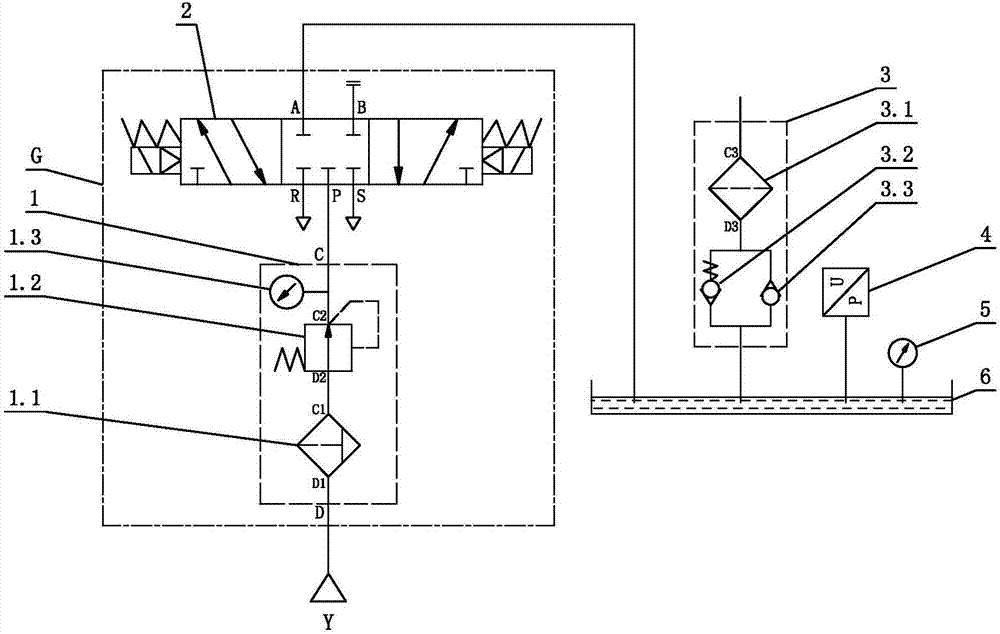

[0018] See figure 1 with figure 2 , The pressurized fuel tank for the injection molding machine includes a tank 6 for storing oil. The top of the tank 6 is provided with an air inlet J, an oil suction port X and an oil return port H; the air inlet J is connected with an air supply device G , The suction port X is connected to the suction end of the servo pump; the air supply device G includes a pneumatic two-piece 1 and a pneumatic reversing valve 2, and the air inlet J is connected to an external compressed air source through the pneumatic reversing valve 2 and the pneumatic two-piece 1 in turn Y. In this structure, the air supply device is provided to make the air pressure inside the box 6 greater than the outside air pressure, thereby improving the pressure of the oil pump suction port, thereby ensuring reliable operation of the hydraulic system of the injection mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com